Conical rolling device

A spheronizing machine and cone technology, which is applied in the field of new machinery and equipment, can solve the problems of inability to roll conical parts and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

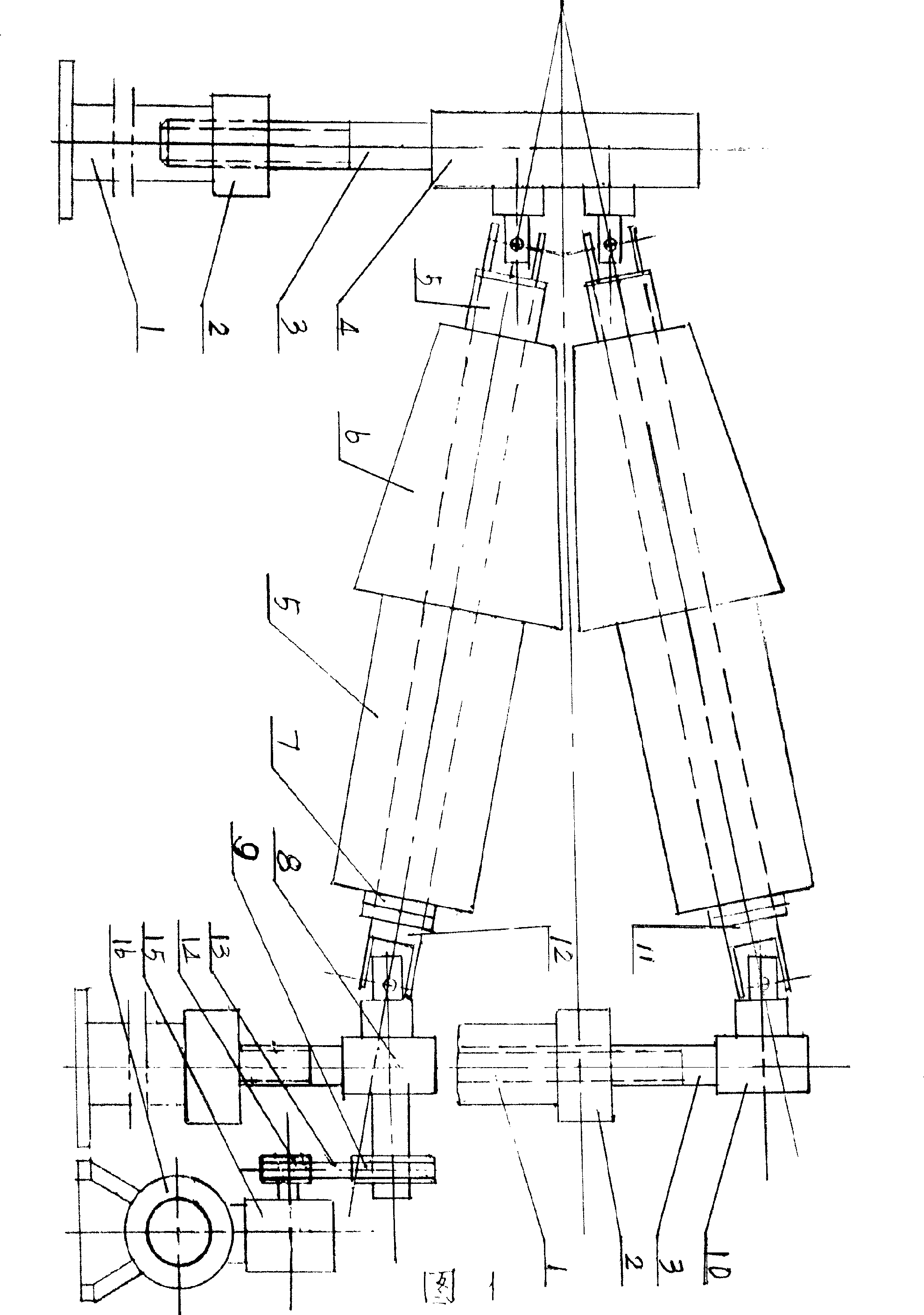

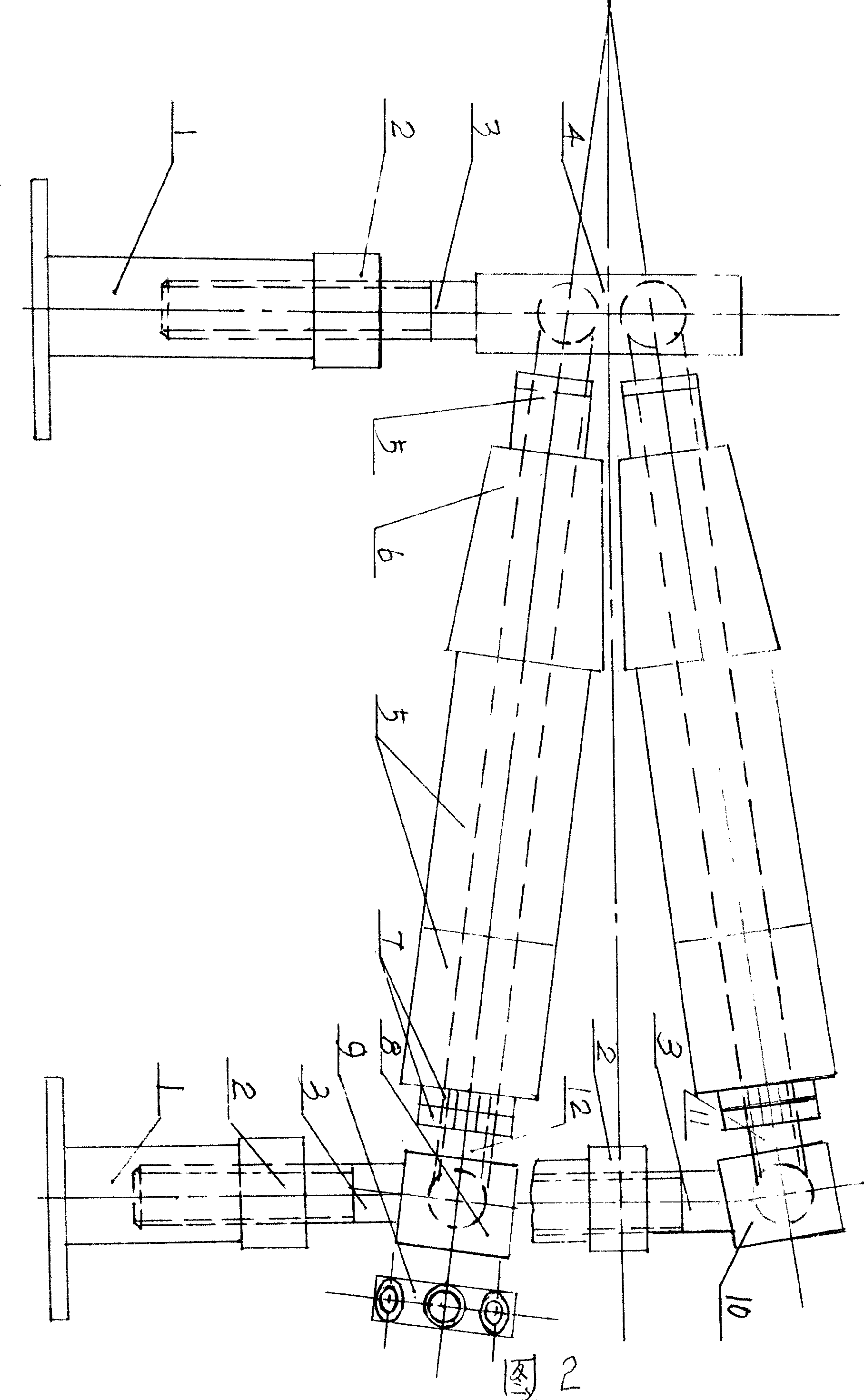

[0009] Attached drawing 1. The main body of the electric-driven conical rolling machine consists of supporting legs 1, screw nut 2, screw 3, supporting disc 4, pad cover 5, tapered roller 6, lock nut 7, lower support sleeve 8, upper support Cover 10, upper roller 11, lower roller 12 form. Power system is made up of large pulley 9, V-belt 13, small pulley 14, worm gear reducer 15, motor 16 several parts. Three rollers are installed on the support disc 4 and the upper support sleeve 10 and the lower support sleeve 8, and their connection mode is to utilize a universal joint. Both ends of the three shafts are integrated with one end of the universal joint, and the other end of the universal joint is fixedly connected with the upper and lower support sleeves of the support disc respectively. The extended line of the central line of one upper roller and two lower rollers intersects at a point, which is called a vertex. The end near the apex is called the apex, and the end farther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com