Elevating mechanism of objective table

A lifting mechanism and stage technology, which is applied to workbenches, manufacturing tools, etc., can solve the problems of inability to adjust the processing requirements of the equipment flexibly, inaccurate transmission, etc., and achieve the effect of flexible stroke changes, accurate transmission, and high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

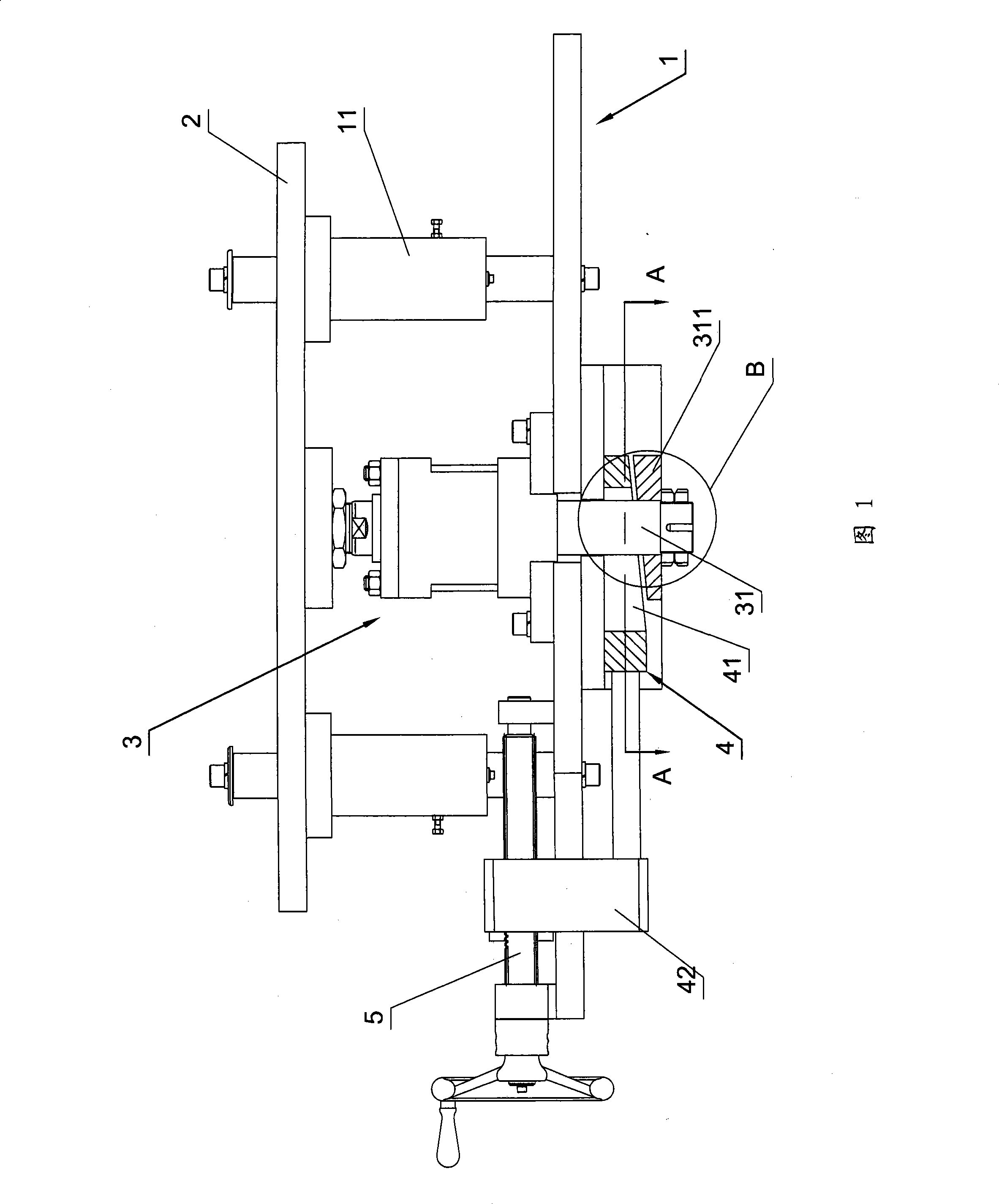

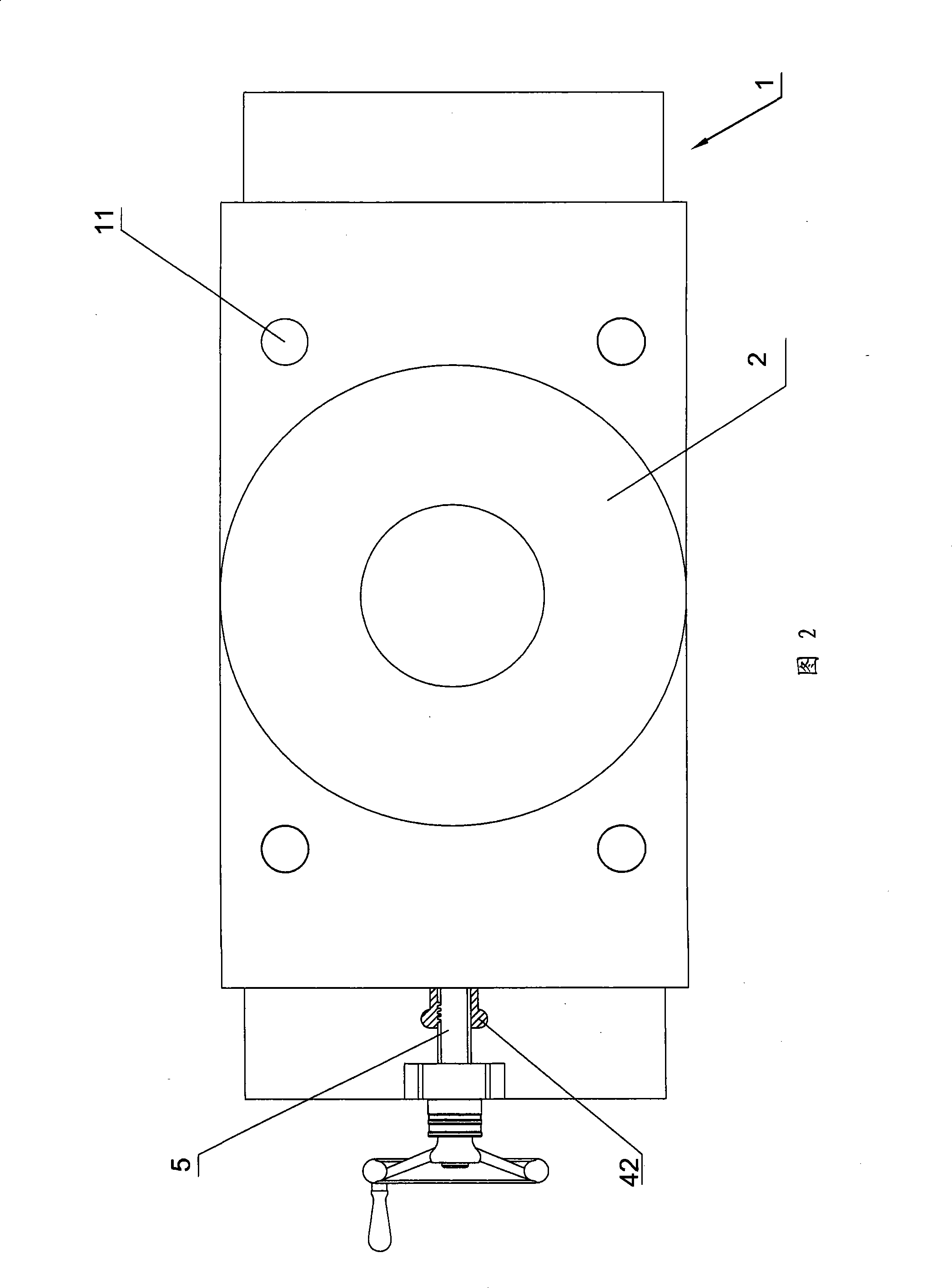

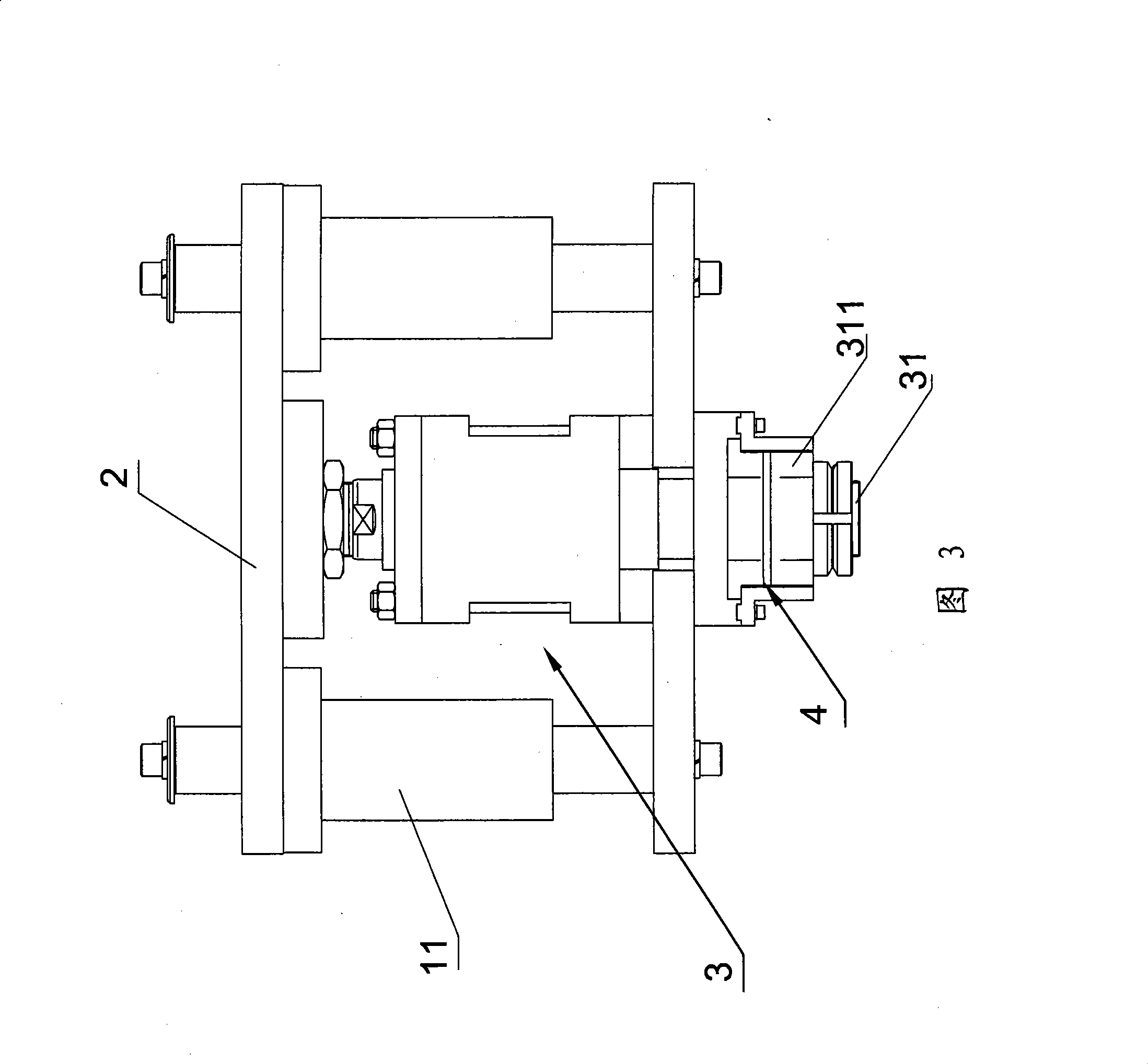

[0013] Referring to accompanying drawings 1 to 5, a lifting mechanism for a stage includes a seat body 1 connected to a supporting object, and a connecting plate 2 fixedly connected to the stage. Usually, the seat body 1 is a large A part of the frame of the equipment, and the connecting plate 2 can also be directly used as a stage for carrying workpieces.

[0014] The seat body 1 has a plurality of guide rods 11 arranged in the vertical direction, the connecting plate 2 is slidably sleeved on the guide rods 11, and the connecting plate 2 can be vertically slid along the guide rods 11 to realize the lifting of the rim ( The "vertical direction" described in this specification refers to the up-down direction in accompanying drawing 1).

[0015] Cylinder 3 is also fixedly arranged on seat body 1, and cylinder 3 adopts double outlet rod cylinder, as shown in accompanying drawing 1, cylinder 3 has piston rod 31 that is arranged along the vertical direction, and the upper end and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com