Catalytic conversion method for preparing aromatic hydrocarbons and light olefins

A catalytic conversion method and technology of low-carbon olefins, applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of increased dry gas yield, underutilization, low yield of aromatics, etc., and achieve the effect of increased selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

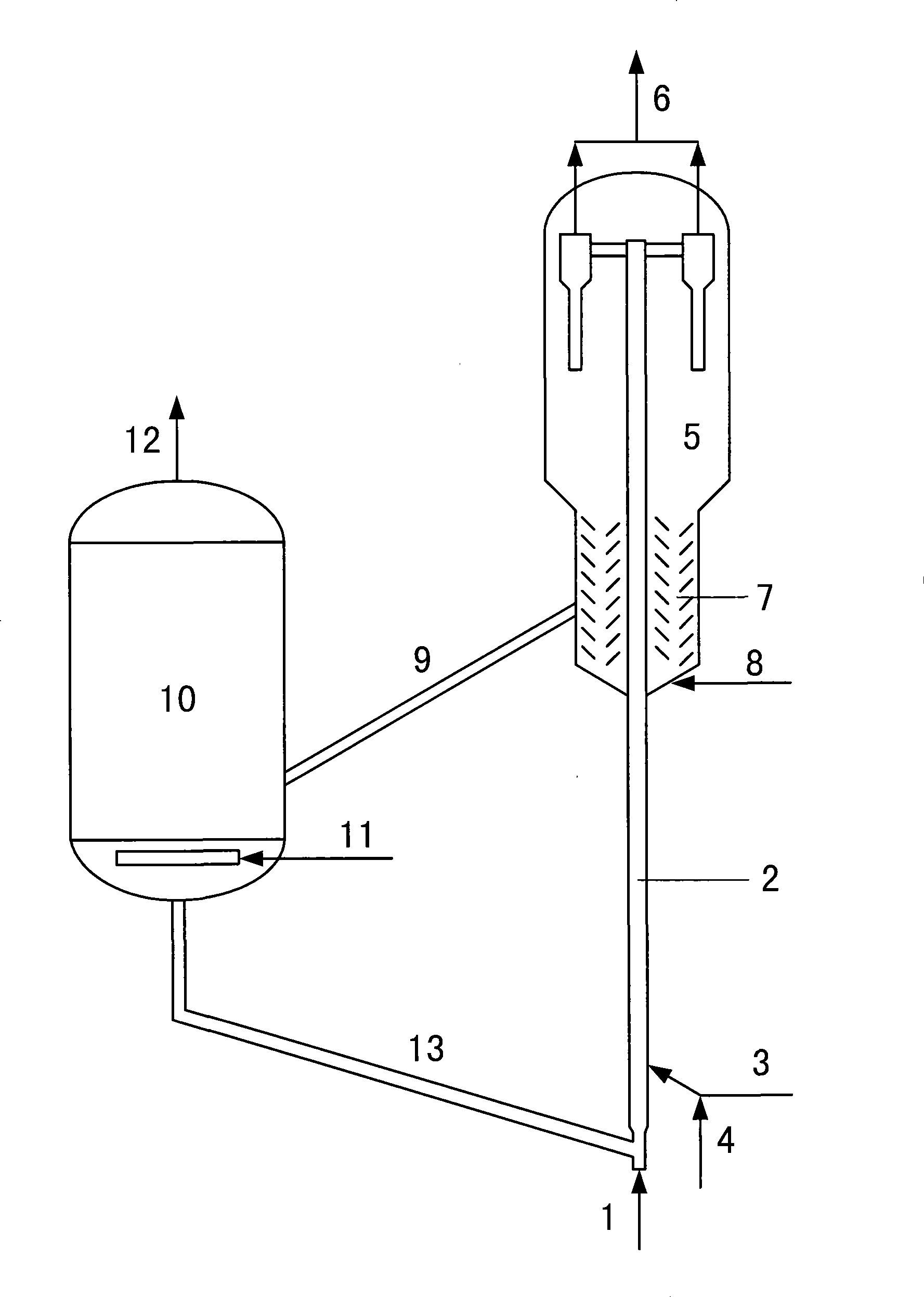

Image

Examples

Embodiment 1

[0036] This example illustrates the use of the method provided by the present invention to prepare aromatics and light olefins by catalytic conversion in a small fluidized bed reactor.

[0037] Distillate oil A with an initial boiling point greater than 165°C listed in Table 1 is used as a raw material for catalytic cracking, and the catalytic cracking catalyst prepared in this example is used to carry out catalytic conversion of distillate oil in a small-scale fluidized bed reaction of continuous reaction regeneration operation. Take experiments with aromatics and light olefins. Distillate A is mixed with preheated high-temperature steam and then enters the fluidized bed reactor. The reaction temperature is 545°C, the top pressure of the reaction is 0.3MPa, and the weight hourly space velocity is 13h -1 , the ratio of agent to oil is 9, and the weight ratio of water vapor to raw material is 0.15, and the catalyst is contacted to carry out catalytic conversion to prepare light...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap