Method for producing safe cone using recycled material

A technology of safety cones and recycled materials, applied in roads, road signs, traffic signals, etc., can solve the problems of perishable color, expensive raw materials, loss, etc., and achieve the effect of non-perishable color, color retention, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

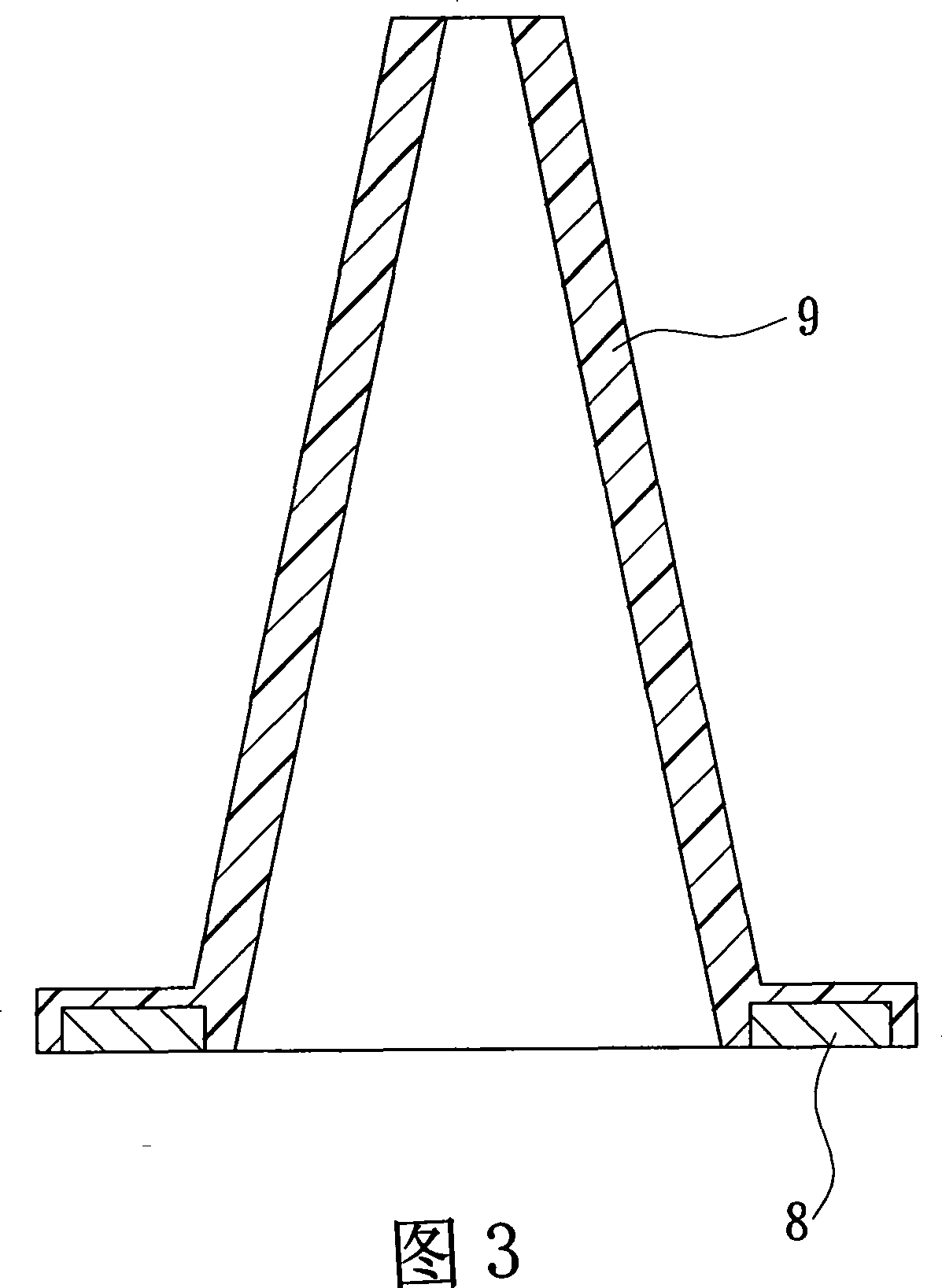

[0022] For preferred embodiments of the present invention, please refer to figure 1 and figure 2 , shown in the figure are all selected preferred embodiments of the present invention.

[0023] The first embodiment of the present invention provides a method for making a safety cone using recycled materials, the steps of which include:

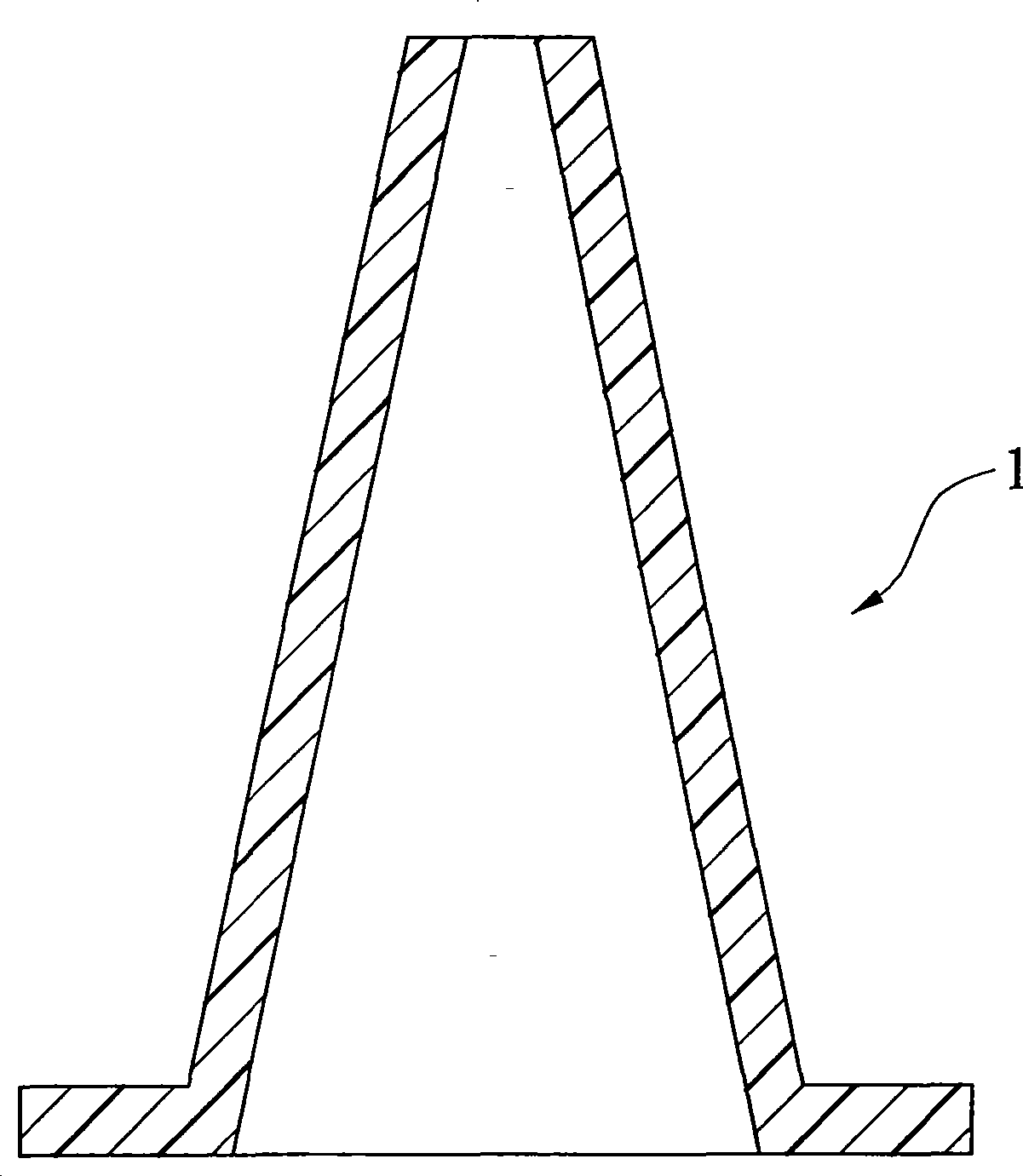

[0024] First set the recycled material in the molding machine, and use the molding machine to make the recycled material into an integrally formed safety cone blank 1. Its structure is as follows figure 1 shown.

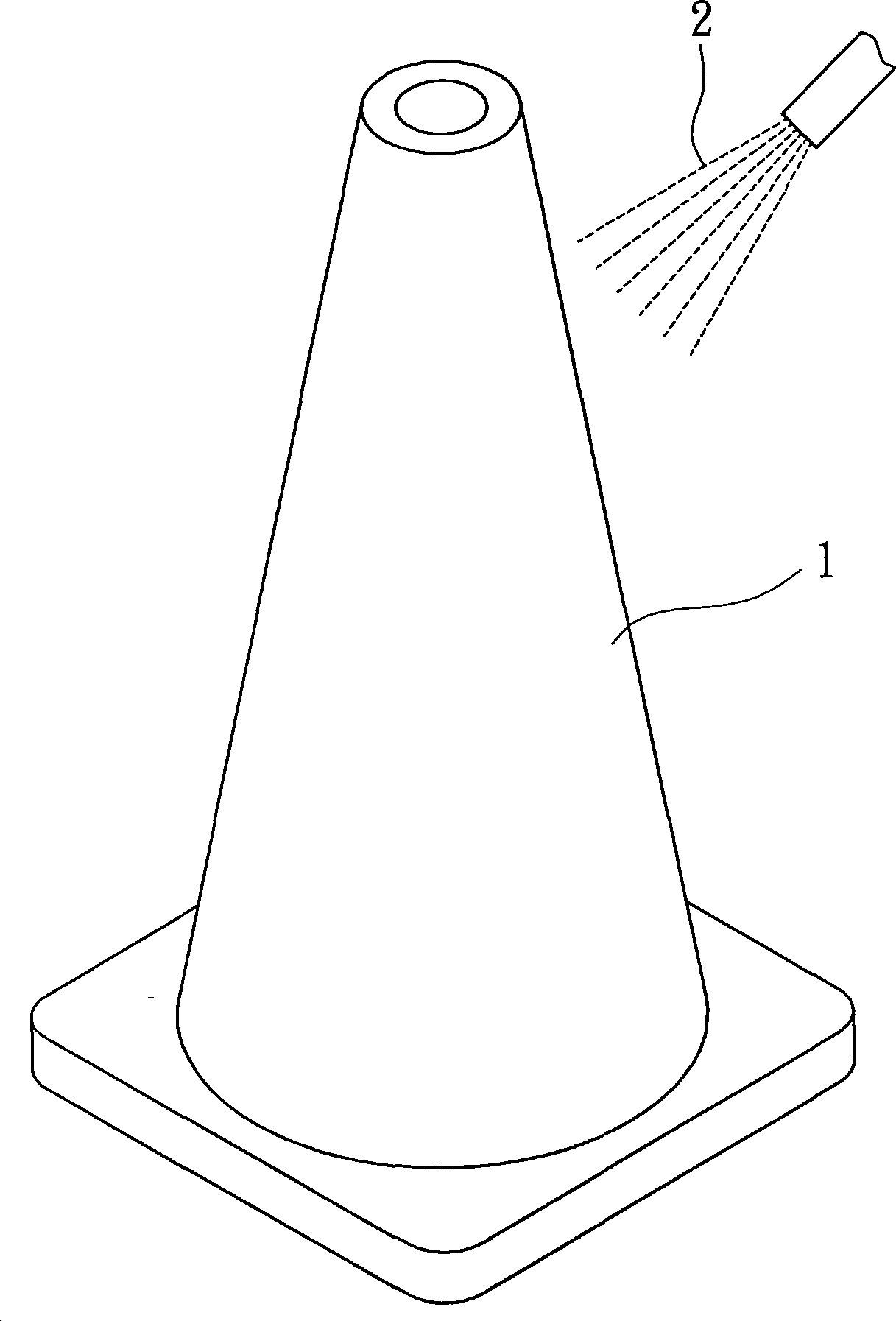

[0025] Utilize the coating 2 that has plastic powder, solvent, dyeing agent again, it is arranged on the surface of this safety cone blank 1, makes safety cone blank 1 become a safety cone with color, as figure 2 As shown, the paint 2 can be sprayed, coated, poured, and dipped to make the surface of the safety cone blank 1 be coated with the paint 2.

[0026] Among them, the plastic powder of the paint and the recycled material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com