Dual clutch transmission of a motor vehicle

A sealing device and clutch technology, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of lifting, adverse effects of sealing, complicated structure of discharge parts, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

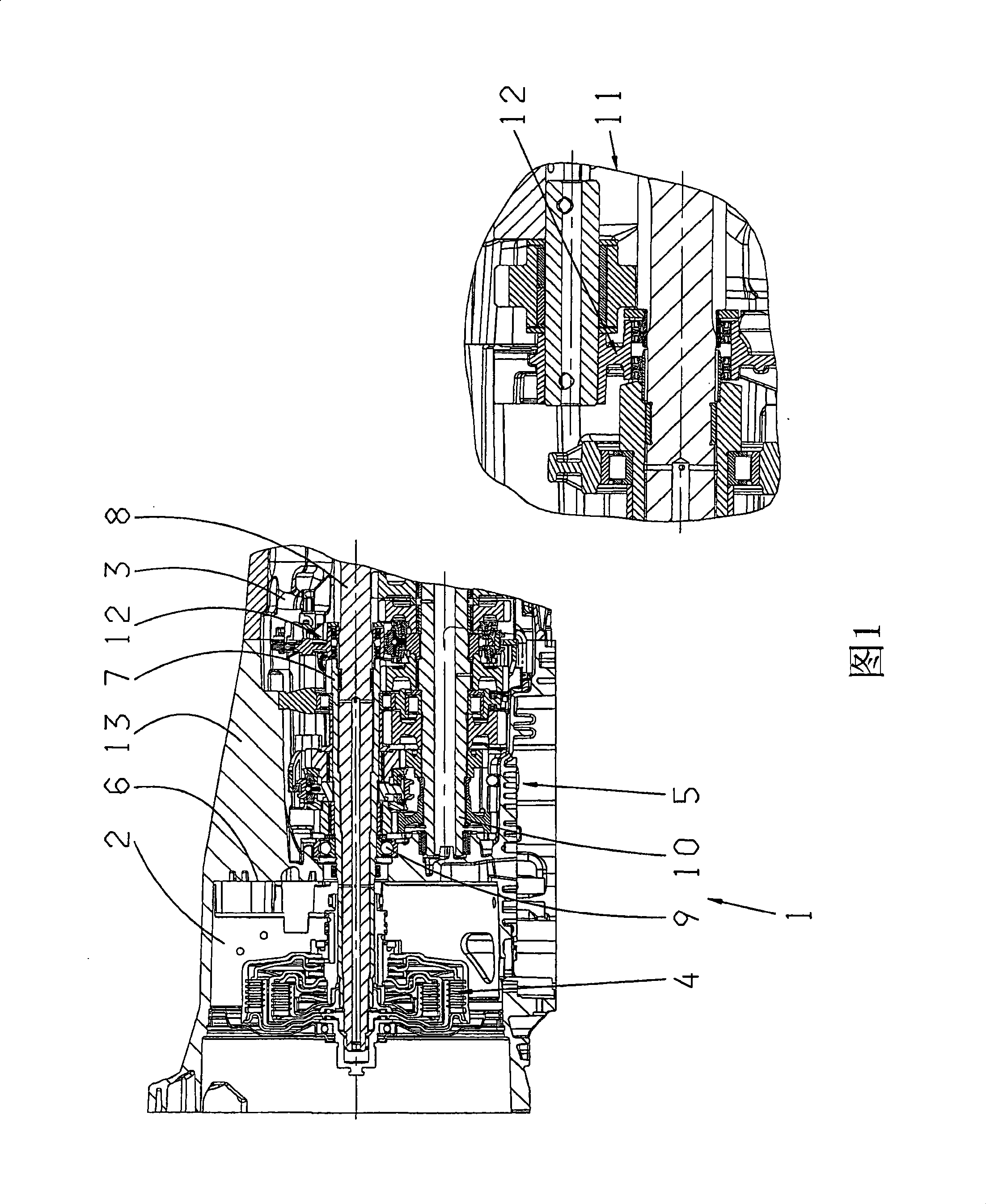

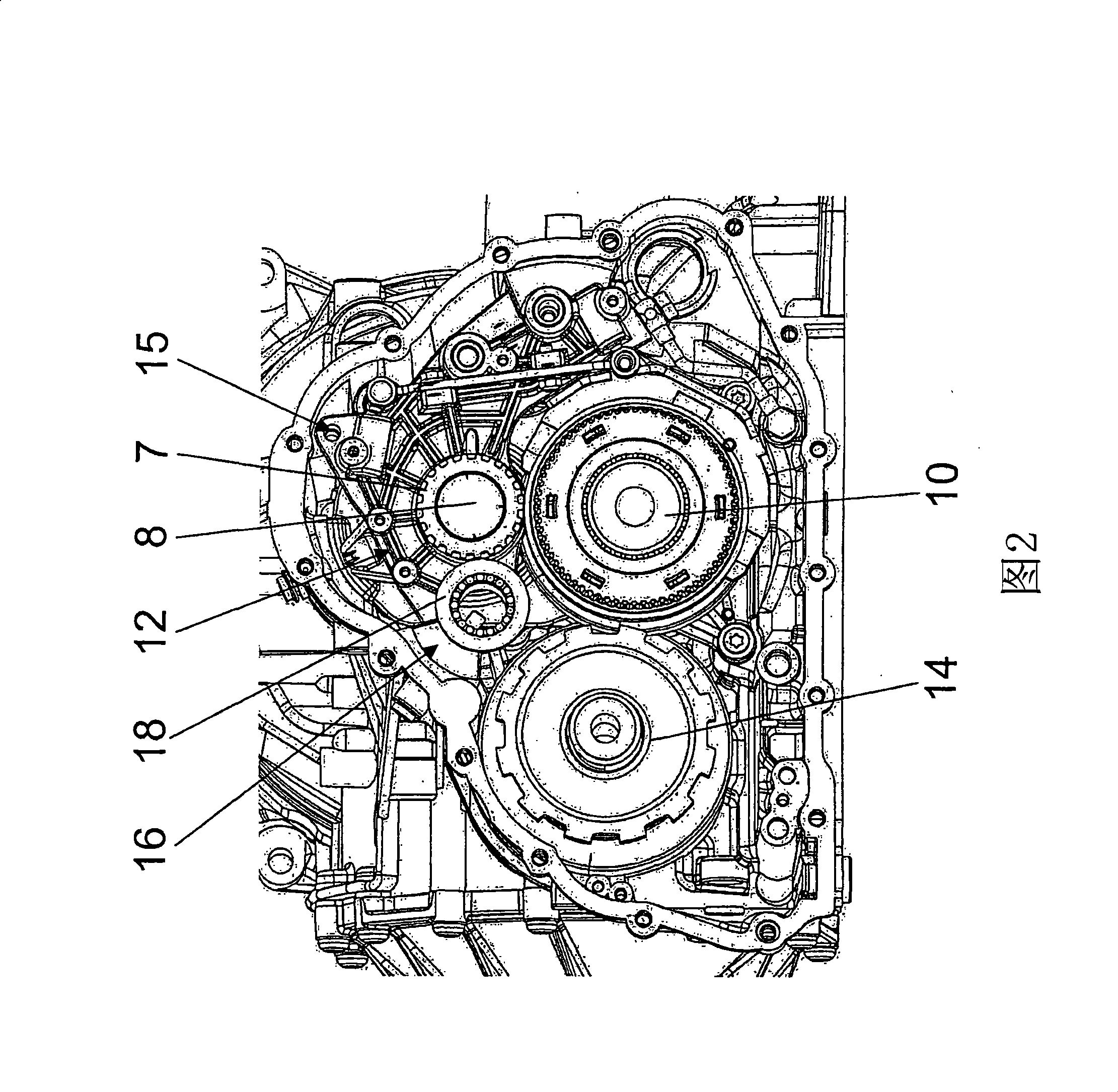

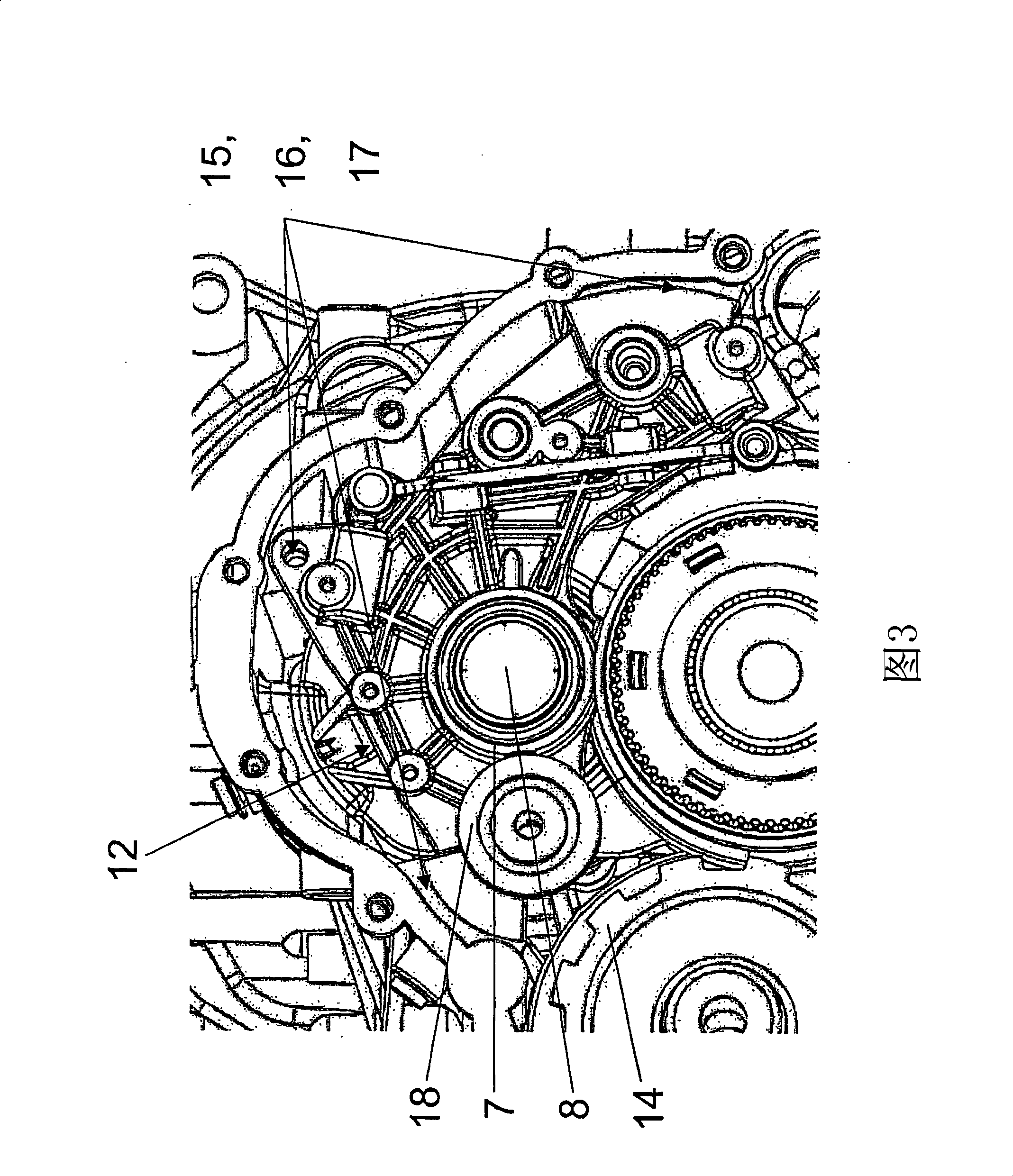

[0031] FIG. 1 shows a multiple clutch transmission 1 of a motor vehicle with separate oil chambers 2 , 3 . The oil chamber 2 is configured as a clutch chamber for accommodating a wet multi-plate clutch 4 . The oil chamber 3 is designed as a transmission chamber, which accommodates the clutch transmission gear set 5 in the sense of two partial transmissions. The oil chambers 2 and 3 are surrounded by a common transmission housing 13 . The principle of operation of multiple clutch transmissions is known per se. Therefore, only the sealing device according to the invention will be described in detail below.

[0032]The oil chambers 2, 3 are separated by a partition 6 through which the two transmission shafts pass. The first transmission shaft is formed as a hollow shaft 7 , through which the second transmission shaft, which is formed as a central shaft 8 , passes coaxially. Each of the two shafts 7 and 8 is rotatably mounted and connected to the single clutch of the multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com