Table stroke control apparatus and control method

A stroke control and control method technology, which is applied to the control of the control device and the stroke control of the machine tool table, can solve the problems of inconvenience, high failure rate and inaccuracy in setting the maximum stroke of the table, and achieve simplified daily maintenance and reliability. High performance and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

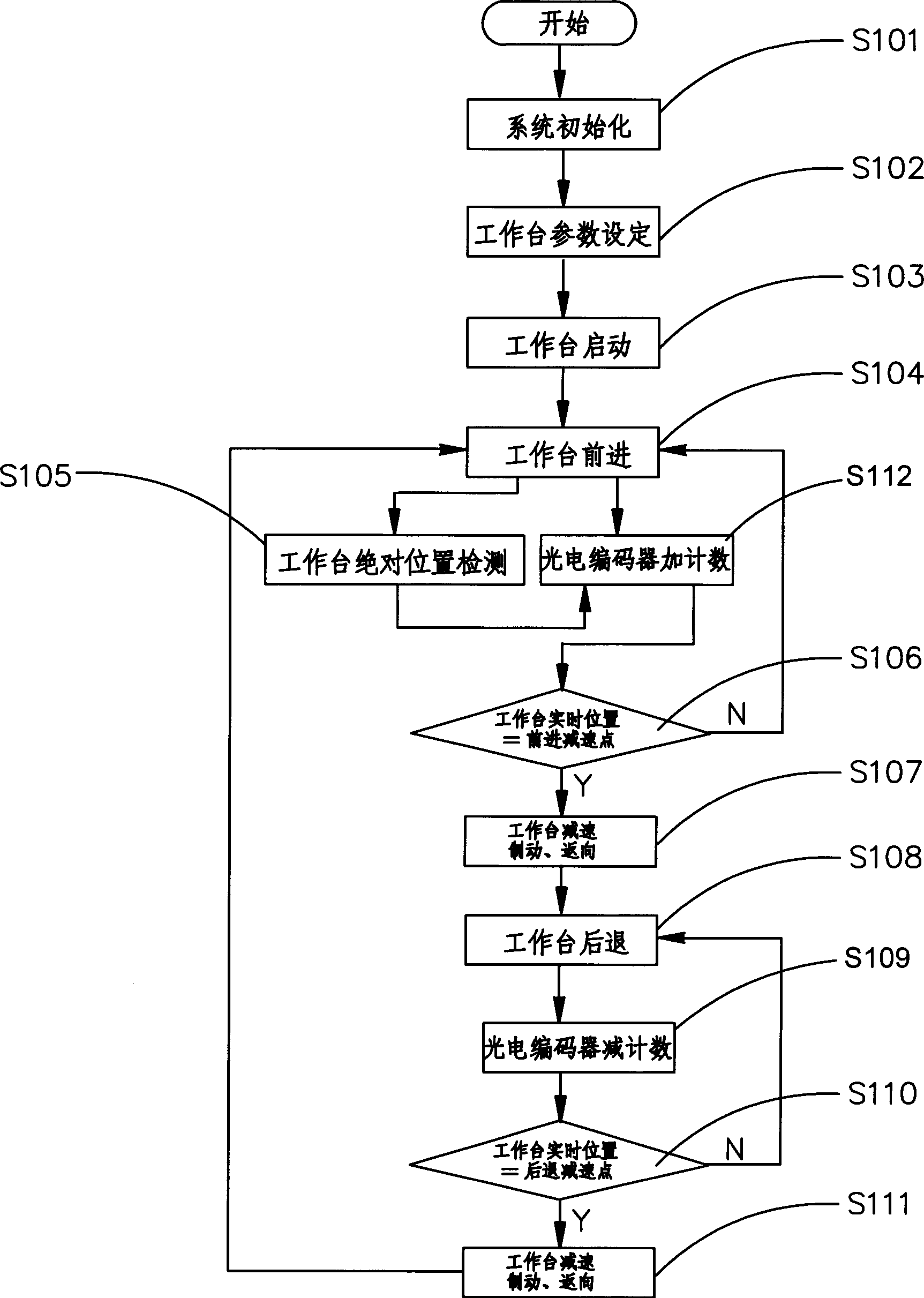

[0030] The principle of the present invention will be described in detail below in conjunction with the accompanying drawings:

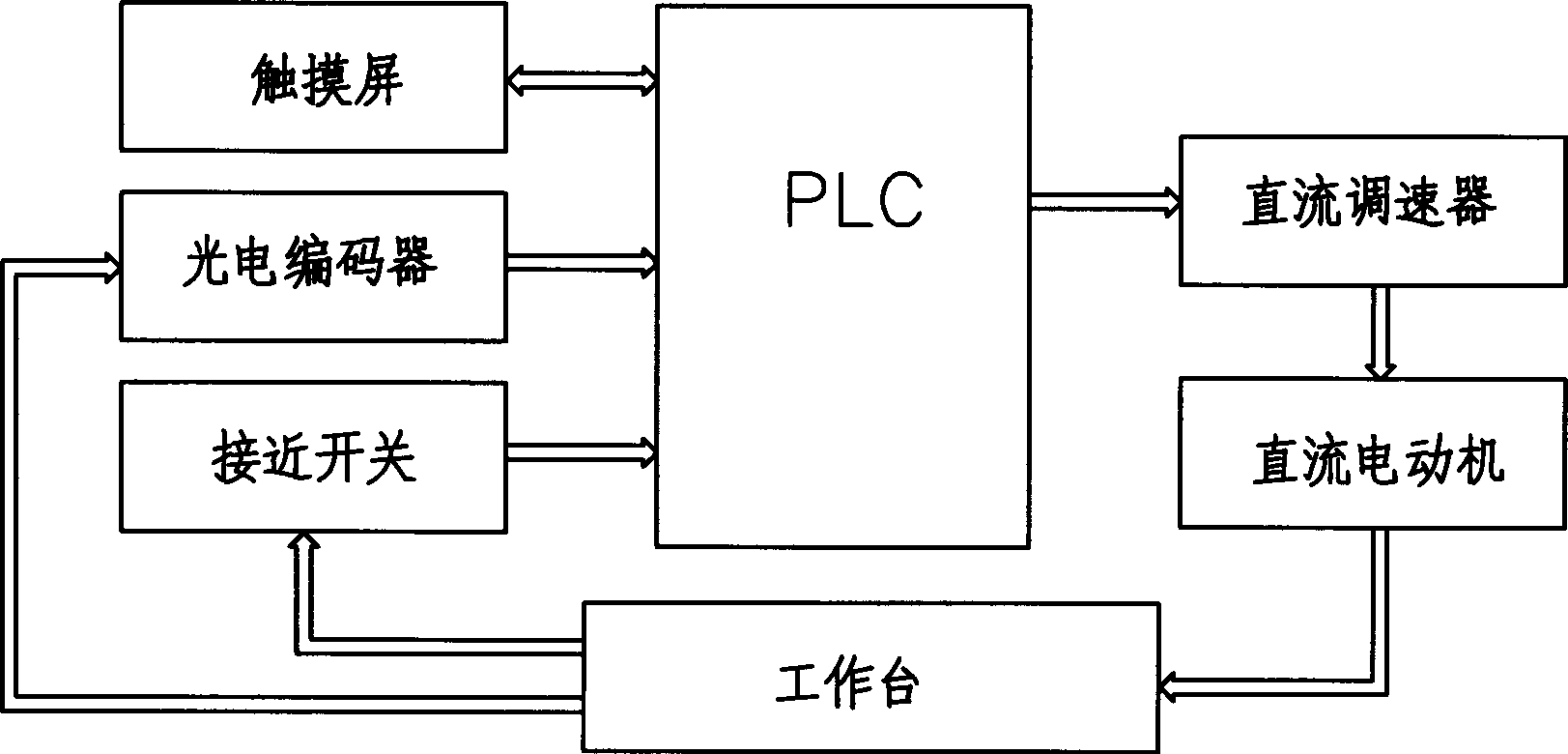

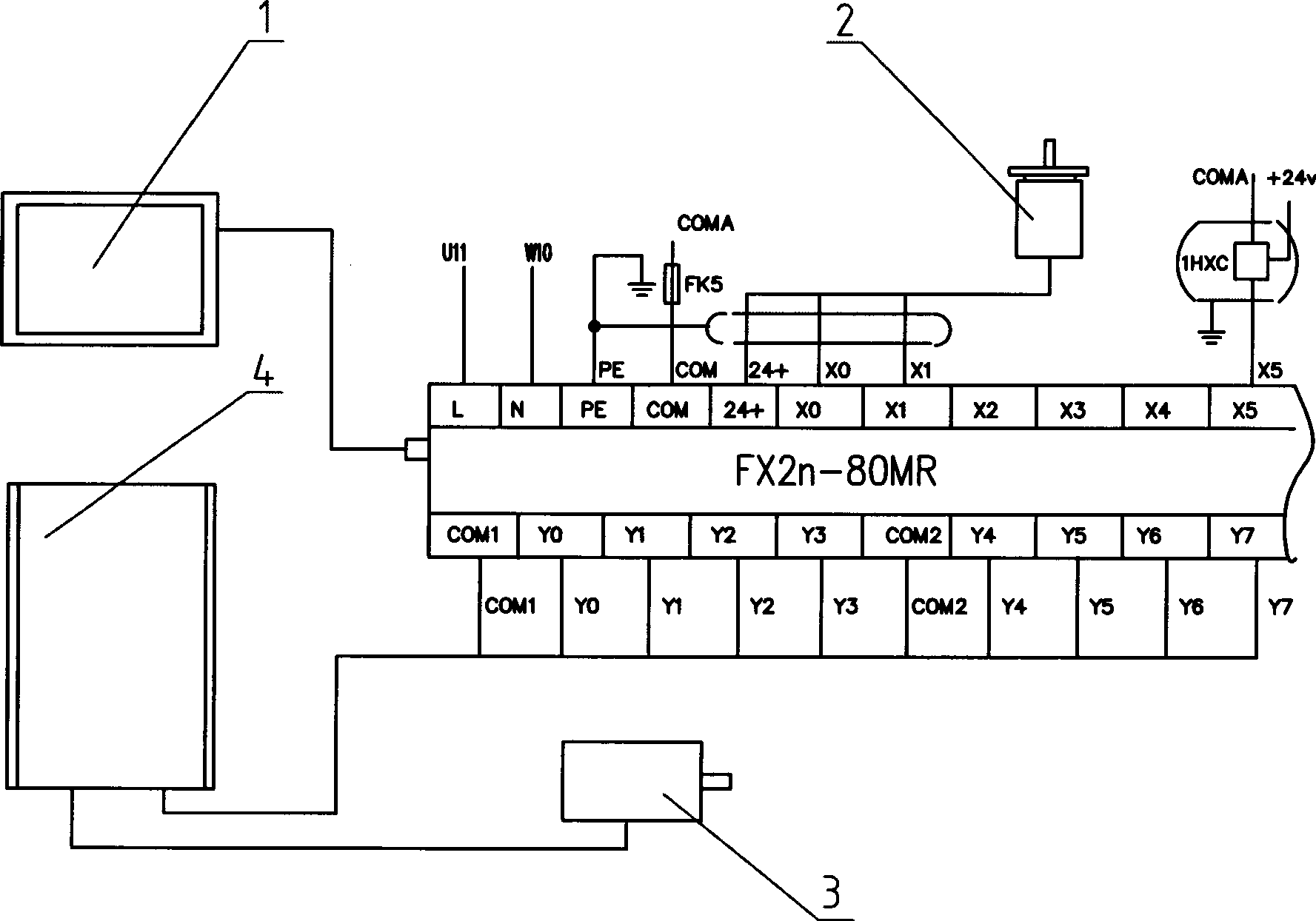

[0031] Refer to the attached Figures 1 to 3 , the utility model workbench travel control device, including a PLC as a control logic device, and a photoelectric encoder 2, its mechanical shaft is coaxial with the worm driving the workbench, used for real-time collection of workbench operating parameters, its output Connect the high-speed counter input port of the PLC, so that the pulse value output by the workbench forward motion photoelectric encoder is input in the bidirectional high-speed counter of the PLC controller; and a touch screen 1, connected to the serial port of the PLC, as The input interface and display interface of the main action command of the workbench; and a DC motor speed controller 3 connected to the PLC output port for receiving PLC control commands and driving the DC motor to drag the workbench back and forth.

[0032] It als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com