Fixer

A fixing device and fixing hole technology, which is applied in the fields of instrument, cooling/ventilation/heating transformation, electrical digital data processing, etc., can solve the problems of complicated assembly steps, increased manufacturing cost, low production efficiency, etc. The effect of improving production efficiency and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

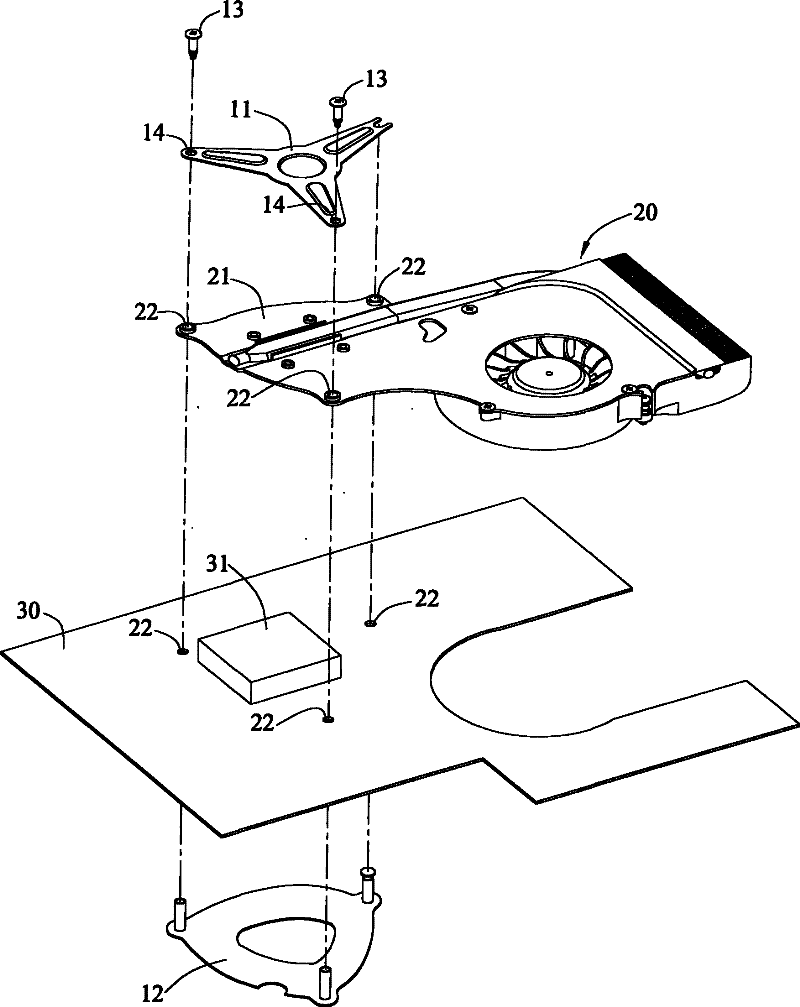

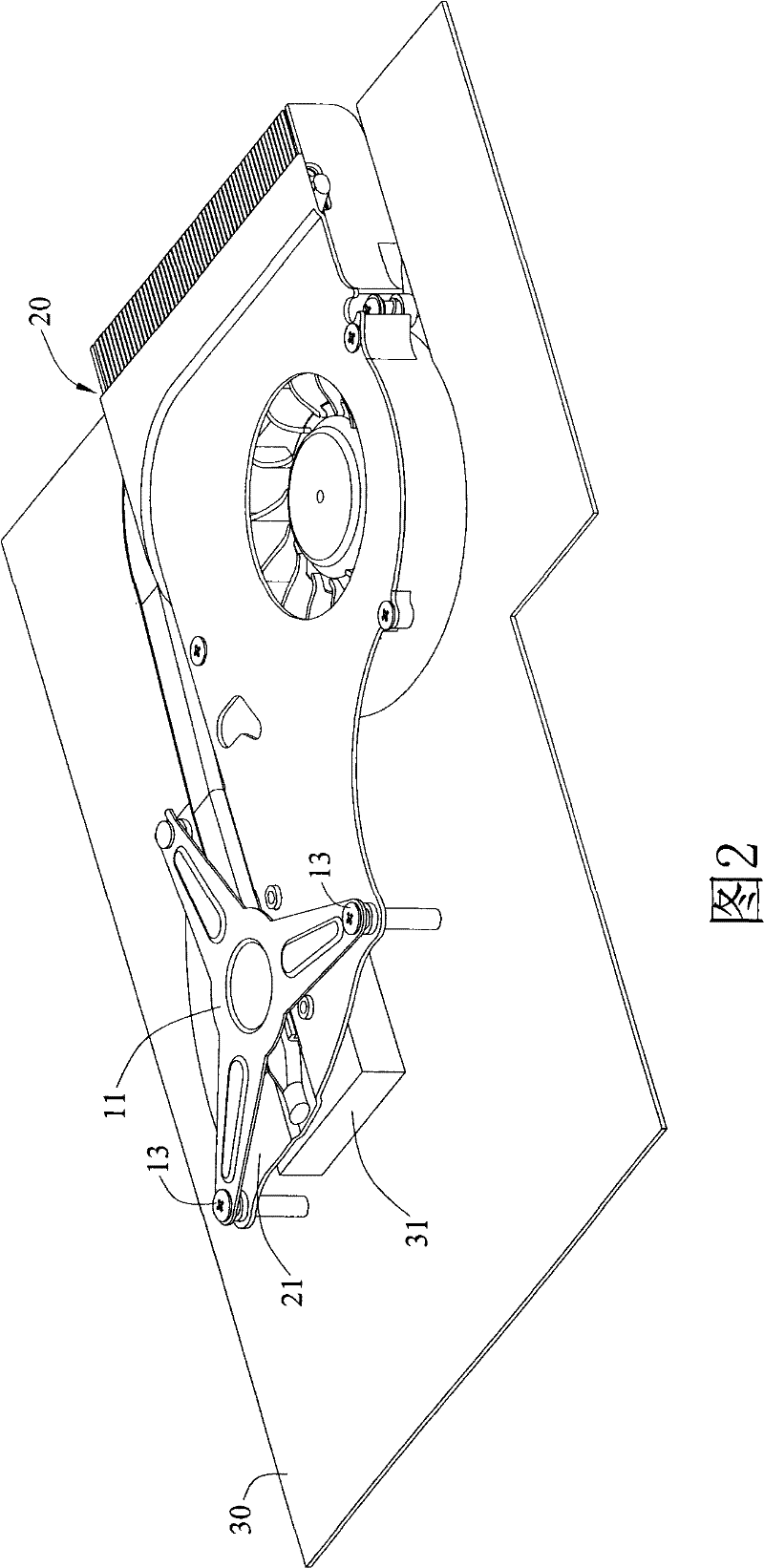

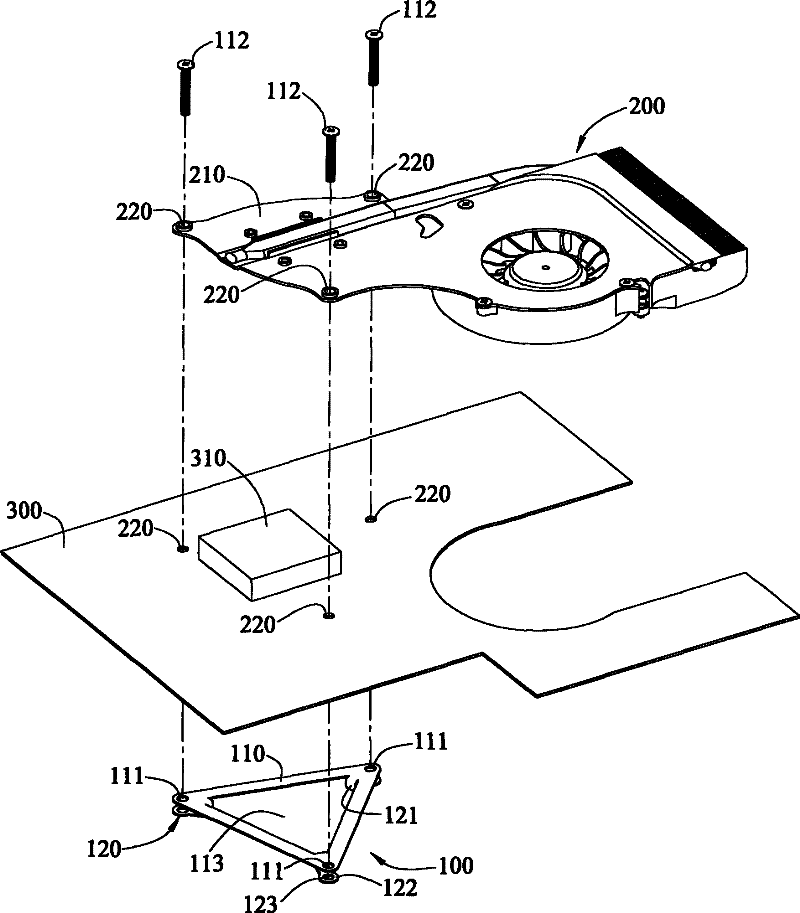

[0049] see image 3 , Figure 4 and Figure 5 As shown, this is a diagram of the first embodiment of the present invention. The fixing device 100 of the present invention is used to attach the heat conducting plate 210 of a heat sink 200 to the heating element 310 on the circuit board 300. The heating element 310 can be a south bridge chip, a north bridge chip, or a central processing unit (CPU), etc. Electronic components that generate high heat energy, and the heat conducting plate 210 and the circuit board 300 are respectively provided with a plurality of fixing holes 220 corresponding to each other.

[0050] The fixing device 100 includes a bracket 110 , a plurality of elastic portions 120 arranged on the bracket 110 at equal angles, and a plurality of locking components 112 . The bracket 110 is disposed on the other side of the circuit board 300 relative to the heat conducting plate 210 , and the bracket 110 has a plurality of through holes 111 corresponding to the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com