Busbar connection system

A busbar connection and connector technology, applied in the field of electrical systems, can solve problems such as high production costs, and achieve the effects of cost reduction, low cost, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

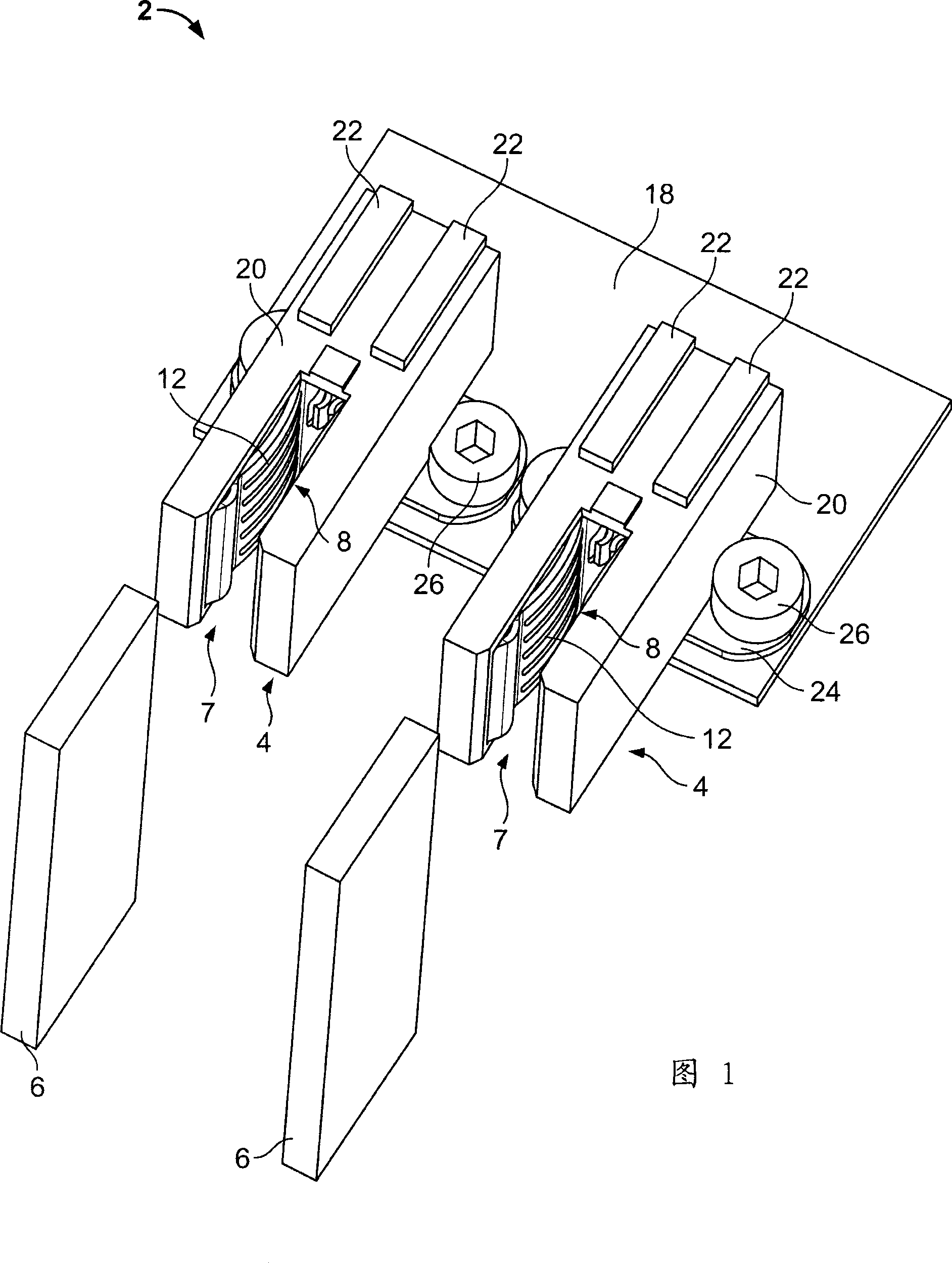

[0030] FIG. 1 shows a schematic perspective view of an exemplary busbar connection system 2 according to the invention. The busbar connection system 2 comprises two pluggable connectors 4 which are fixed side by side to the printed circuit board 18 via fixings 24 and screws 26 . Alternatively, the mount 24 may be secured to the printed circuit board 18 by press-fit contacts or soldering. Each connector 4 has a U-shape with an opening 7 opening forward away from the printed circuit board 18 . Contact members 8 are arranged on each side of each opening 7 extending substantially over the entire height of the opening. Each contact member 8 has a curved shape with an arcuate contact area 12 protruding into the opening 7 . The connectors 4 are covered by respective housings 20 made of plastic.

[0031] Two guide rails 22 are arranged on the rear top end of each housing 20 . Guide rails 22 are arranged to accommodate corresponding protrusions (not visible) formed on the top end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com