Rotary printing press

A technology for printing machines and printing mechanisms, applied in printing machines, rotary printing machines, printing, etc., can solve problems such as multiple structural spaces, and achieve the effect of reducing structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

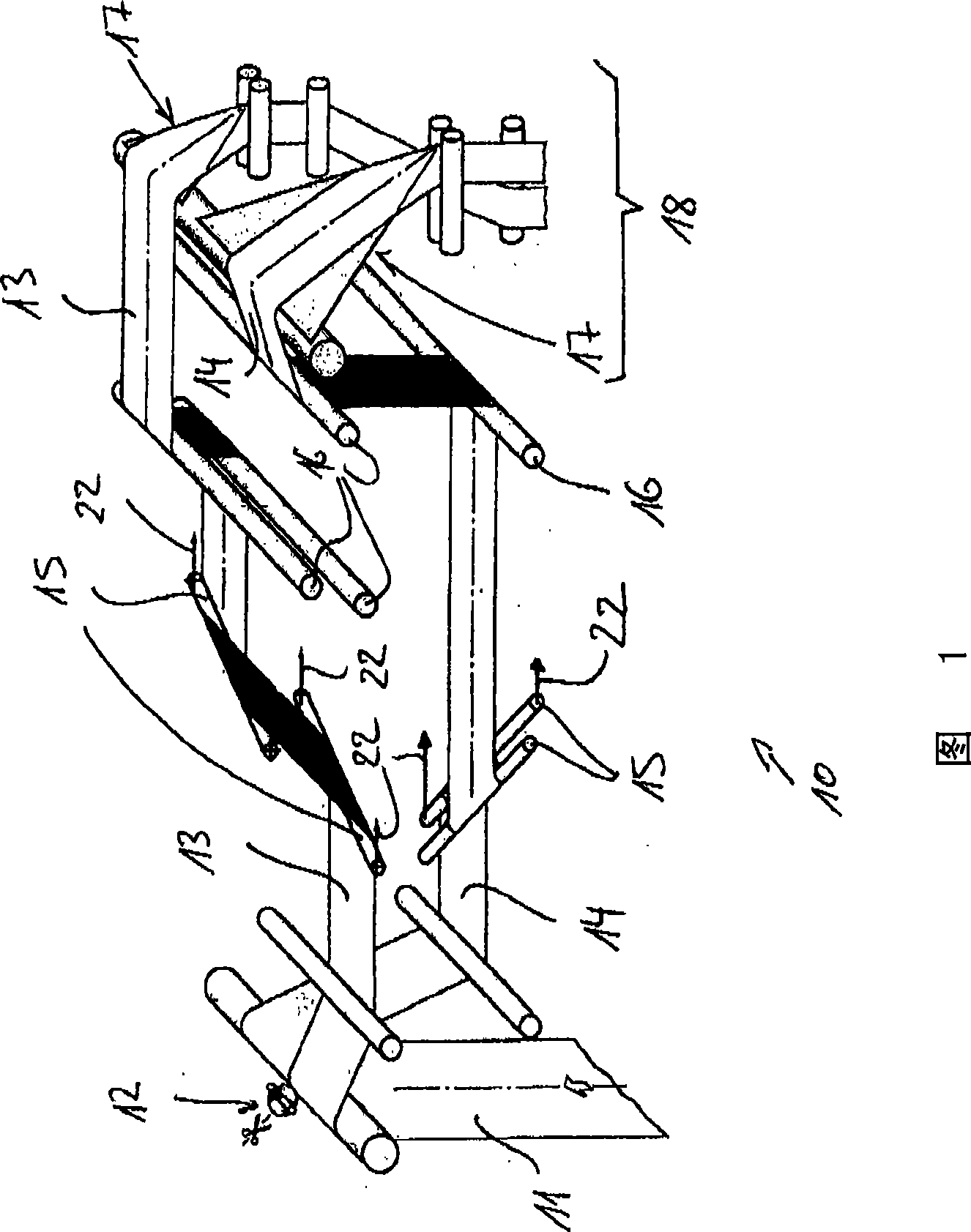

[0010] The invention relates to a web-fed printing press with a plurality of printing units for printing at least one track of printed material and a folding unit. In the region of the folding mechanism, samples can be cut out from one or each track of printed material by transverse cutting. Furthermore, at least one longitudinal fold and / or at least one transverse fold can be formed in the region of the folding means. A so-called turning structure and folding structure are installed between the printing mechanism and the folding mechanism.

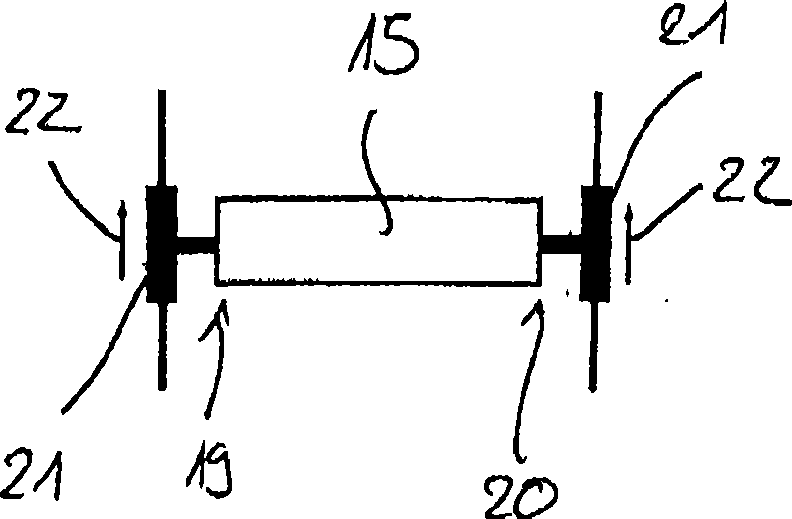

[0011] FIG. 1 shows a partial view from a web-fed printing press in the region of a turning structure 10, wherein in the region of the turning structure 10 of FIG. The cutting device 12 divides into two sub-tracks 13 , 14 by longitudinal cutting. The sub-tracks 13 , 14 can be transported via guide rollers 15 , 16 towards a folder straightener 17 of a folding mechanism 18 of the turning structure 10 . In the area of the folder straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com