Ejection condition adjustment apparatus, droplet ejecting apparatus, and ejection condition adjustment method and program

A technology for adjusting devices and conditions, which is applied in the field of spraying conditions, can solve the problems of increased production costs and reduced production rates of large heads, and achieve the effects of increasing production rates and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Embodiments of the present invention will now be described by taking an inkjet large head including a plurality of small heads as an example.

[0077] Elements for which no specific drawings or descriptions are given here may be realized by prior art in the relevant technical field.

[0078] The embodiments described below are merely examples, and the present invention is not limited thereto.

[0079] (A) Spray condition adjustment method

[0080] (A-1) Adjustment method suitable for monochrome inkjet head

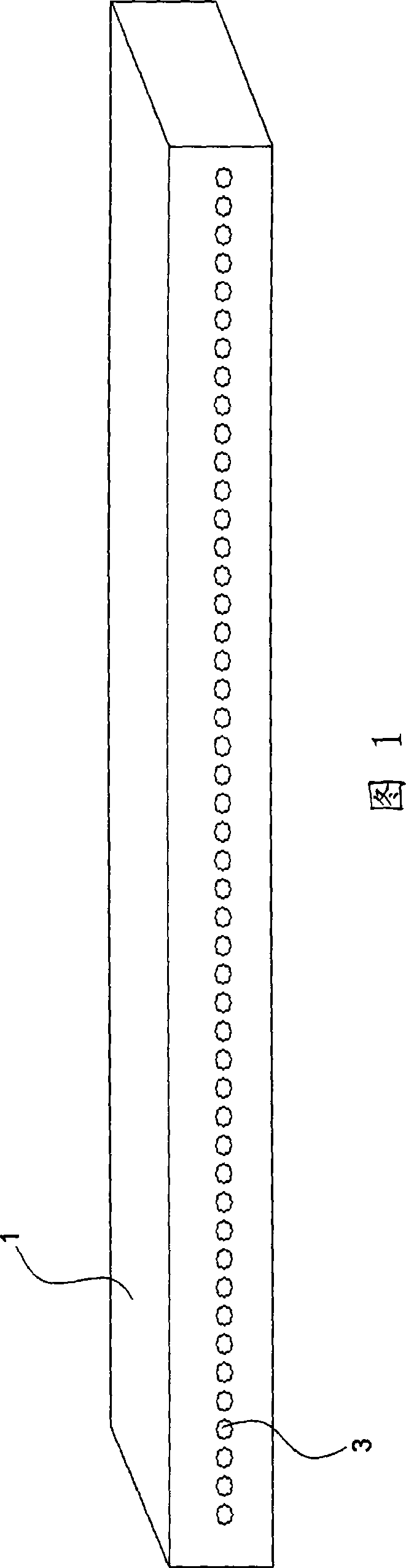

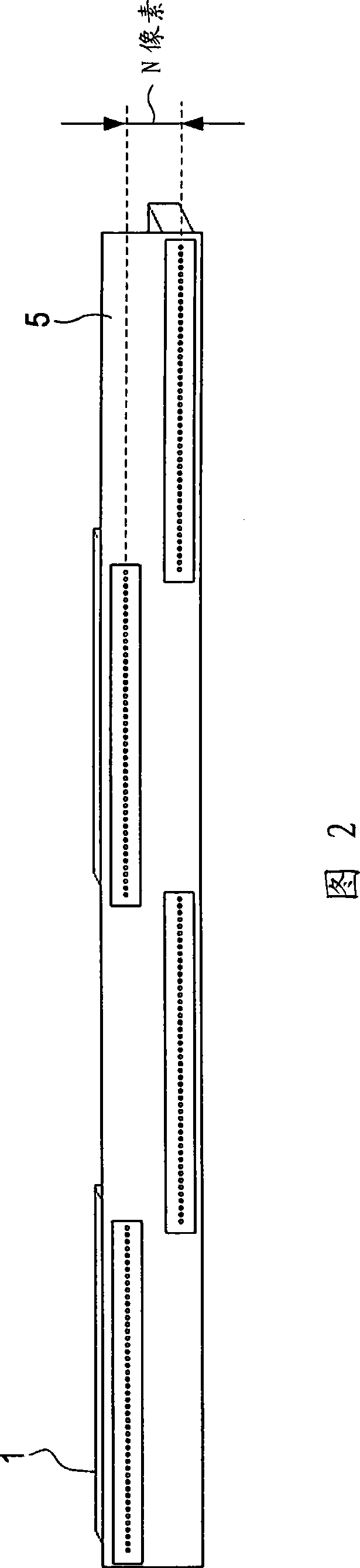

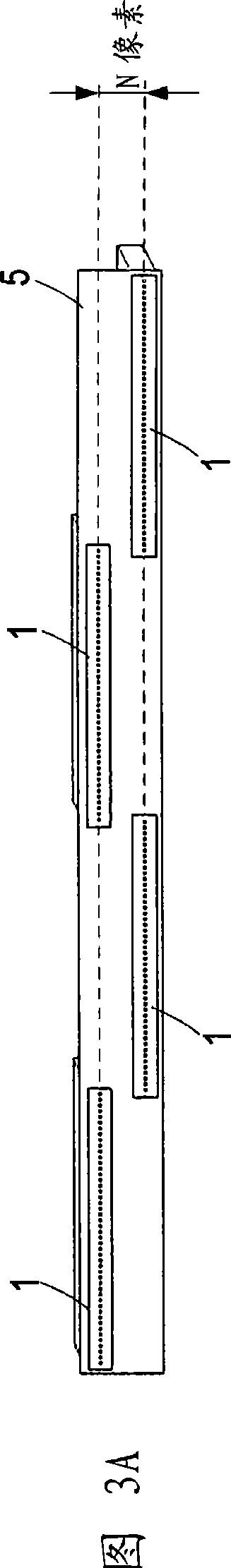

[0081] An example of a large head for monochrome printing will be described below. Fig. 11 shows an example structure of a bulk head 11 for monochrome printing. As shown in FIG. 11 , the large head 11 is provided with small heads 13 at staggered positions along the longitudinal direction. Each small head 13 has a row of a plurality of orifices 3 (dots shown on the small head 13).

[0082] (a) Example adjustment method 1

[0083] 12A to 12C show the reason why ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com