Intellectualized tridimensional storage device

A technology of equipment and walking mechanism, which is applied in the field of storage equipment, can solve the problems of wasting land resources and human resources, occupying a large area of flat storage, and not having intelligent management, so as to improve management efficiency, occupy a large area of passageways, and save The effect of land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

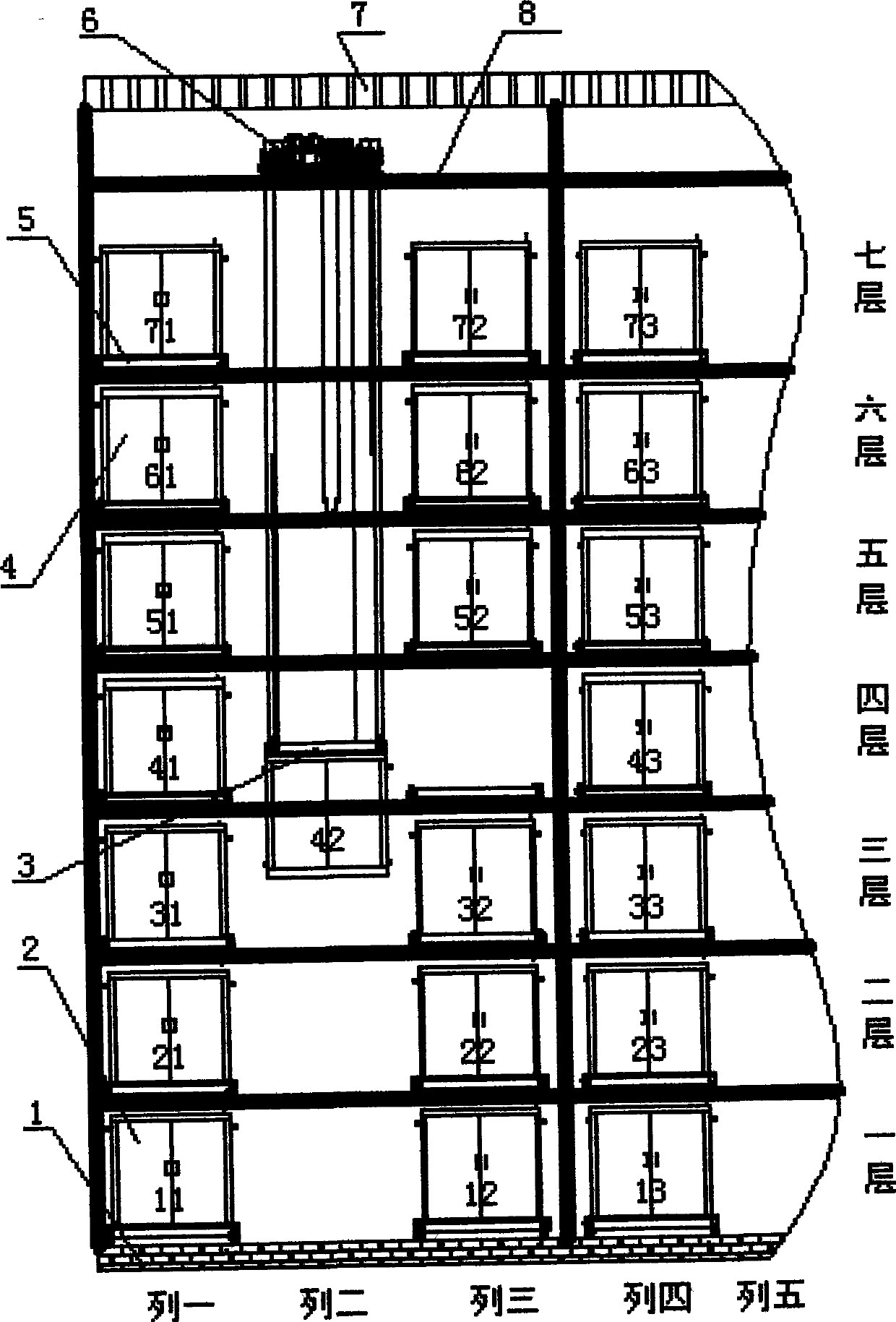

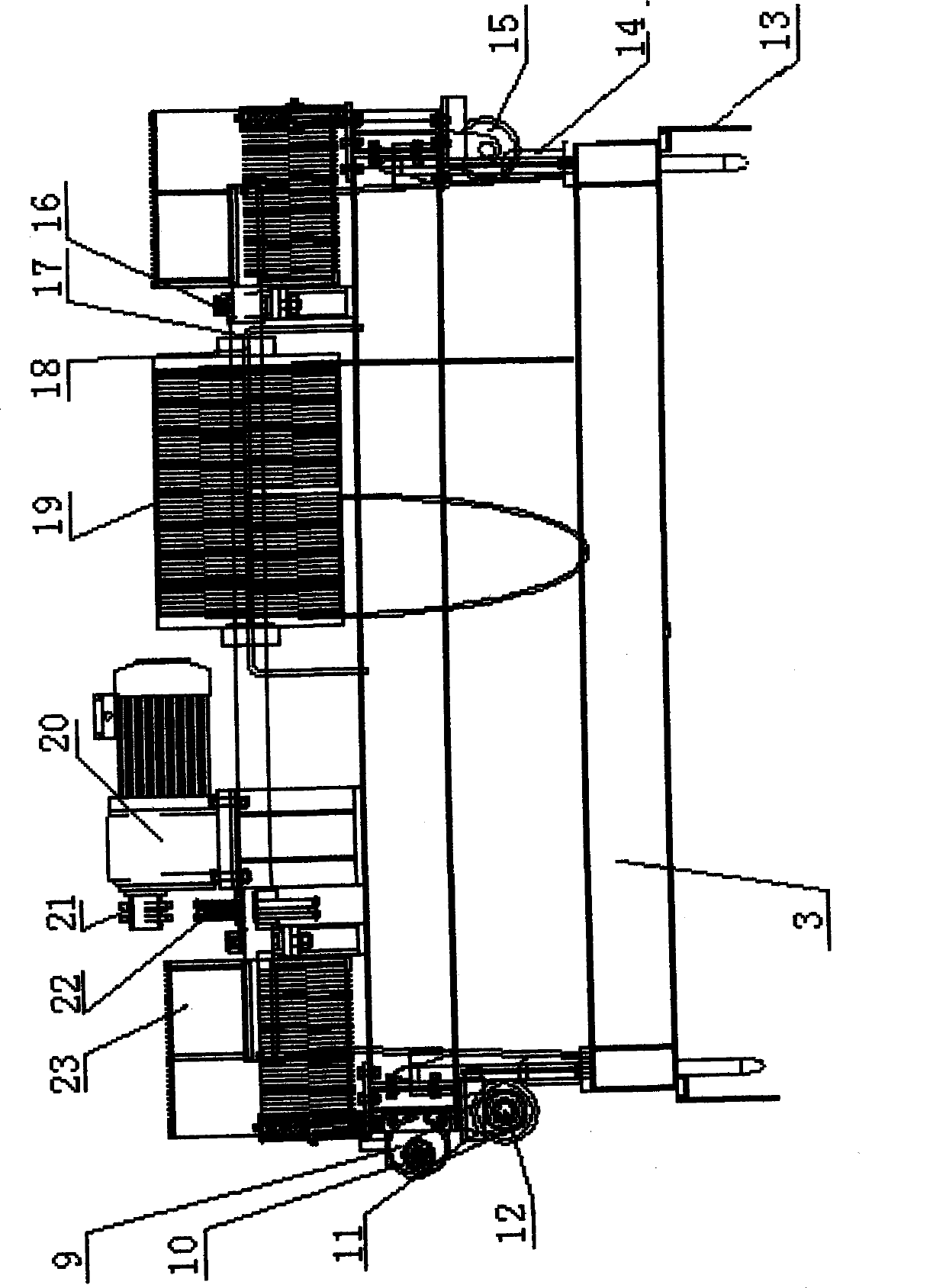

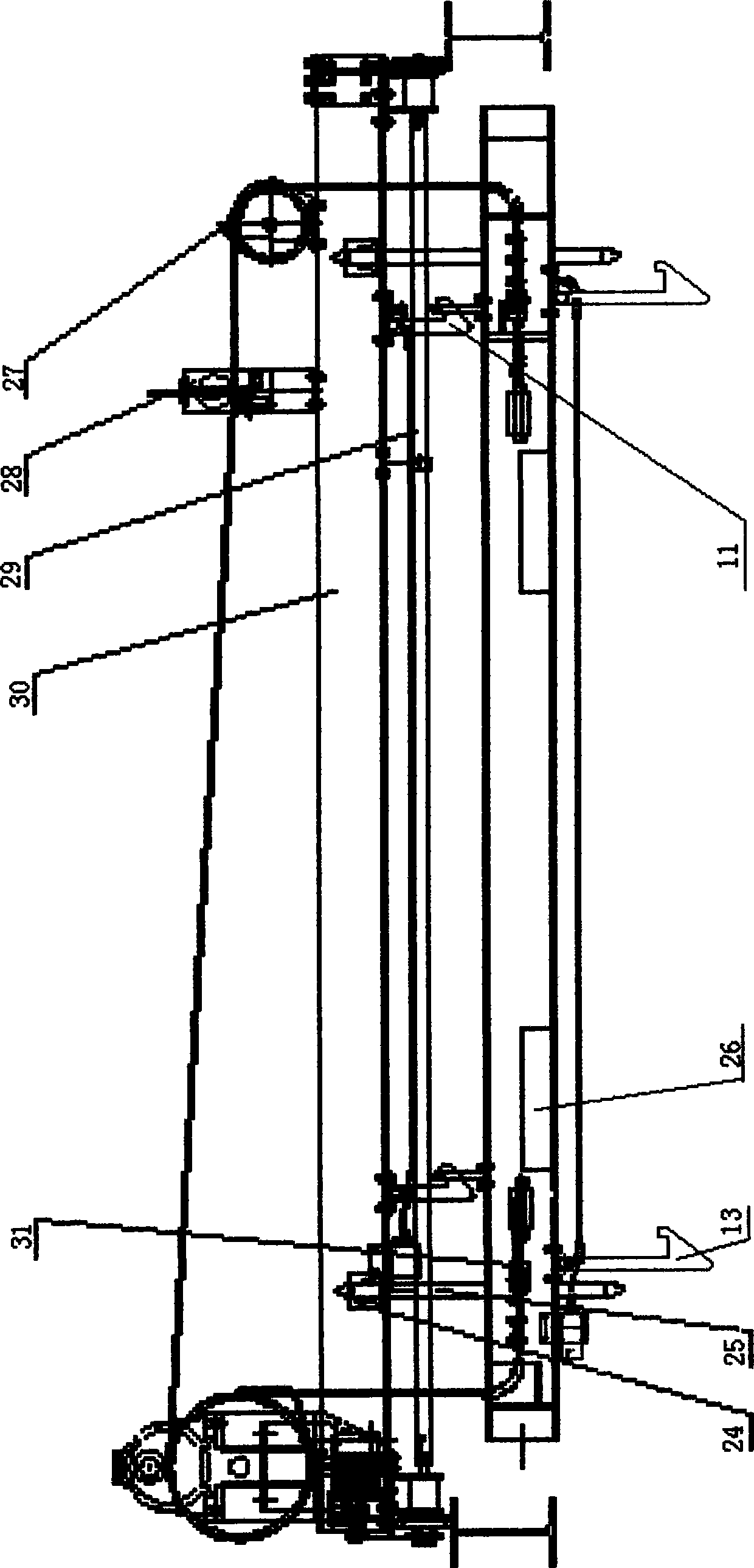

[0026] see figure 1 , describing the operation process of the intelligent three-dimensional storage equipment of the present invention, the traversing main vehicle 6 moves to the row corresponding to the No. Box No. 42 remains in the original position, and the other upper cargo boxes in the same column are moved horizontally away from the column by the movement of the traverse trolley; after the main traveling vehicle 6 moves in place, it contacts the travel switch installed on the steel structure frame 8 to make the horizontal movement The transfer vehicle 6 sends out the carrier frame 3 for a downward movement. After the carrier frame 3 is accurately positioned by the guide stalk 25 and the guide horn seat 34 on the upper container 4, it descends to the top of the No. 42 upper container and contacts it, and is installed on the carrier. The positioning switch at the lower part of the longitudinal beam of the device 3 works, and the spare hook 13 is lowered to the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com