IF steel cage type annealing process

An annealing process and steel cover technology, which is applied in the annealing process field of IF steel produced by bell furnace, can solve the problems of huge investment, steel plate can not meet the deep drawing performance, etc., and achieve the effect of excellent deep drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] 1. Material selection

[0021] In large-scale production, two kinds of Ti+Nb-IF steel and Ti+P-IF steel cold-rolled plates are selected as experimental materials as the implementation object of the annealing process of the present invention, and their chemical composition and hot-rolling process are shown in Table 2 and Table 3. Made into the size required for the experiment (20mm×300mm).

[0022] Table 2 Chemical composition of two IF steels (wt%)

[0023]

[0024] Note: 1-represents Ti+Nb-IF steel; 2-represents Ti+P-IF steel

[0025] Table 3 Two kinds of IF steel hot rolling process systems

[0026]

[0027] Note: 1-represents Ti+Nb-IF steel; 2-represents Ti+P-IF steel

[0028] 2. Annealing scheme

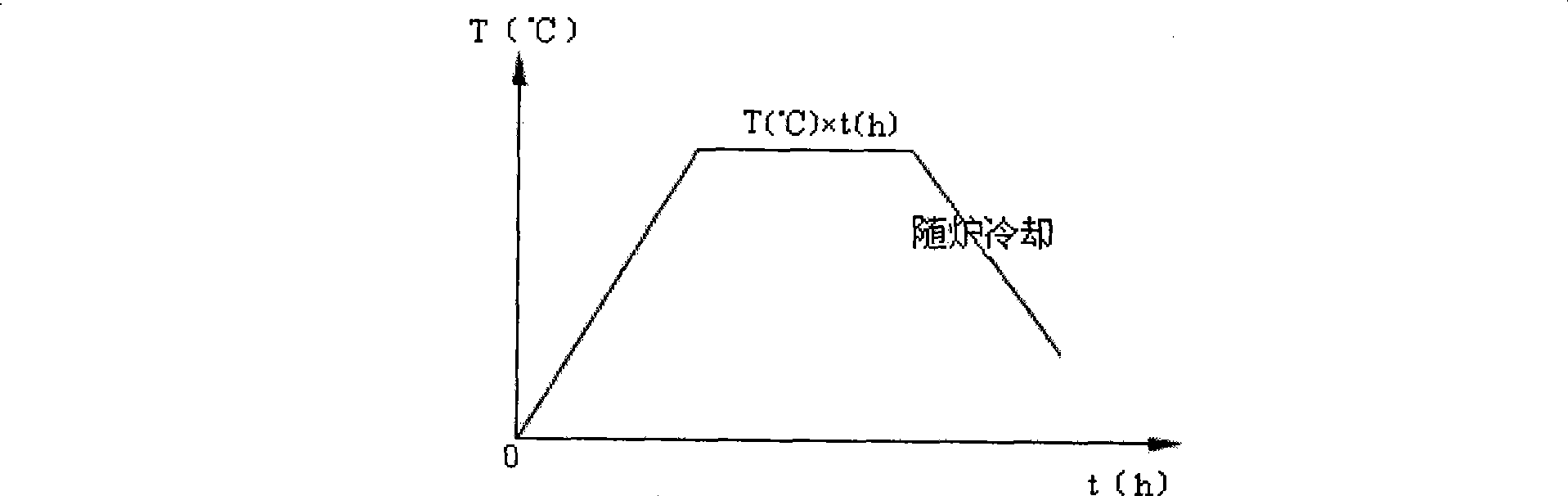

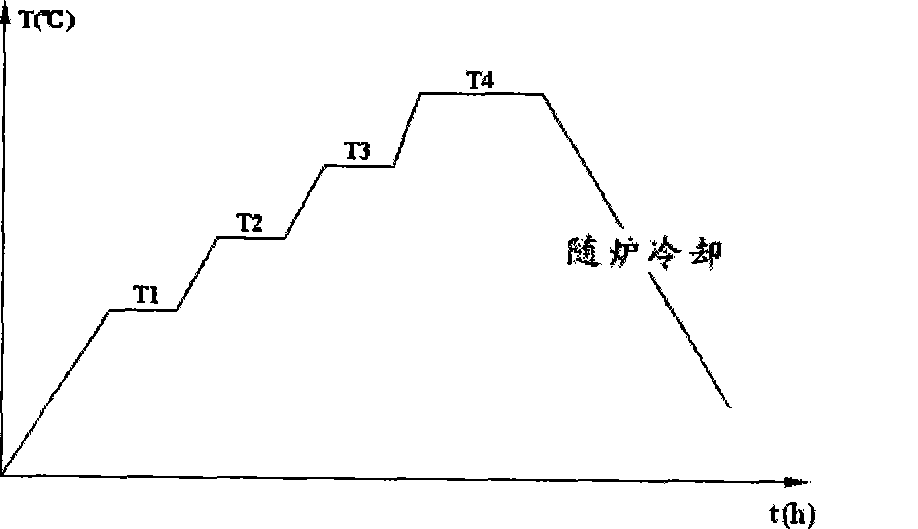

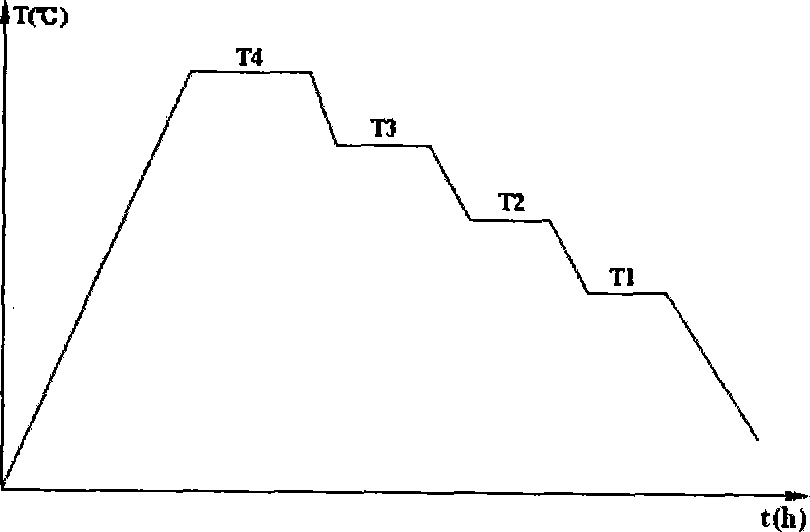

[0029] The selected IF steel cold-rolled plates were annealed in the laboratory according to the following three staged insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com