Pole tube and lift magnet

A pole tube and lift technology, applied in the direction of electromagnets, magnets, electromagnets, etc. with armatures, can solve problems such as thermal overload, deformation of structural components, and inability to design, so as to achieve low manufacturing costs, improve manufacturing quality, and avoid overheating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

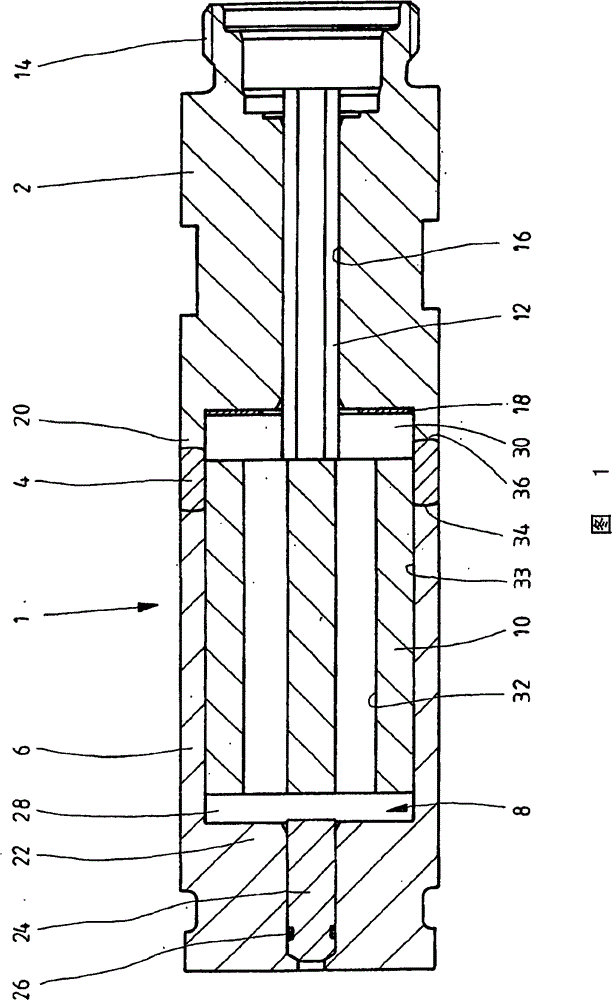

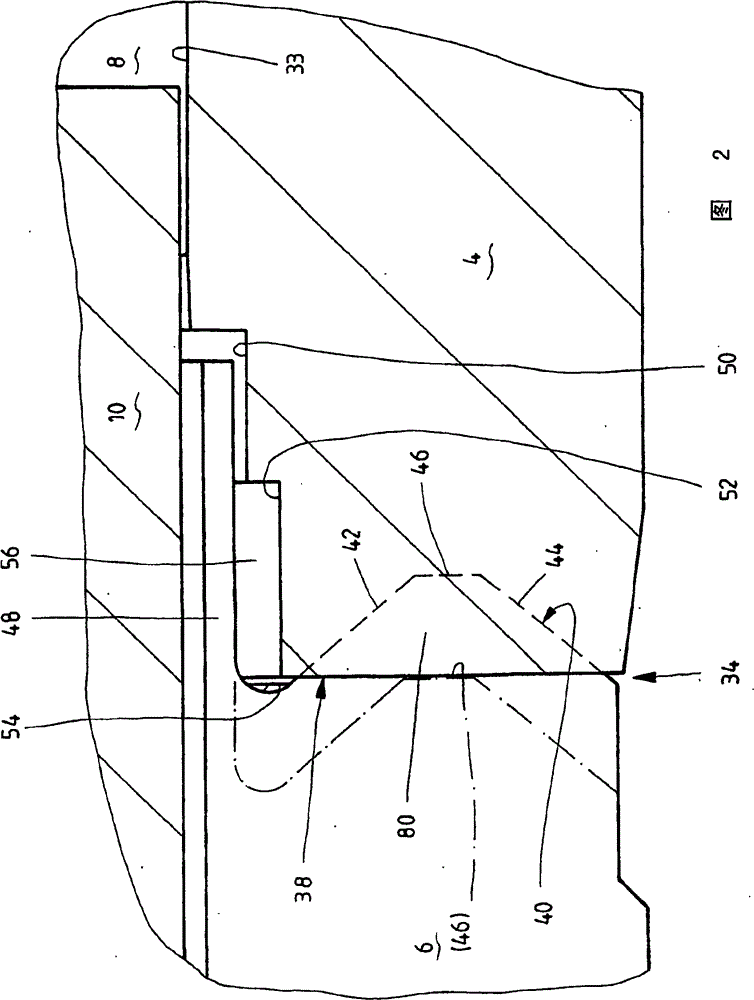

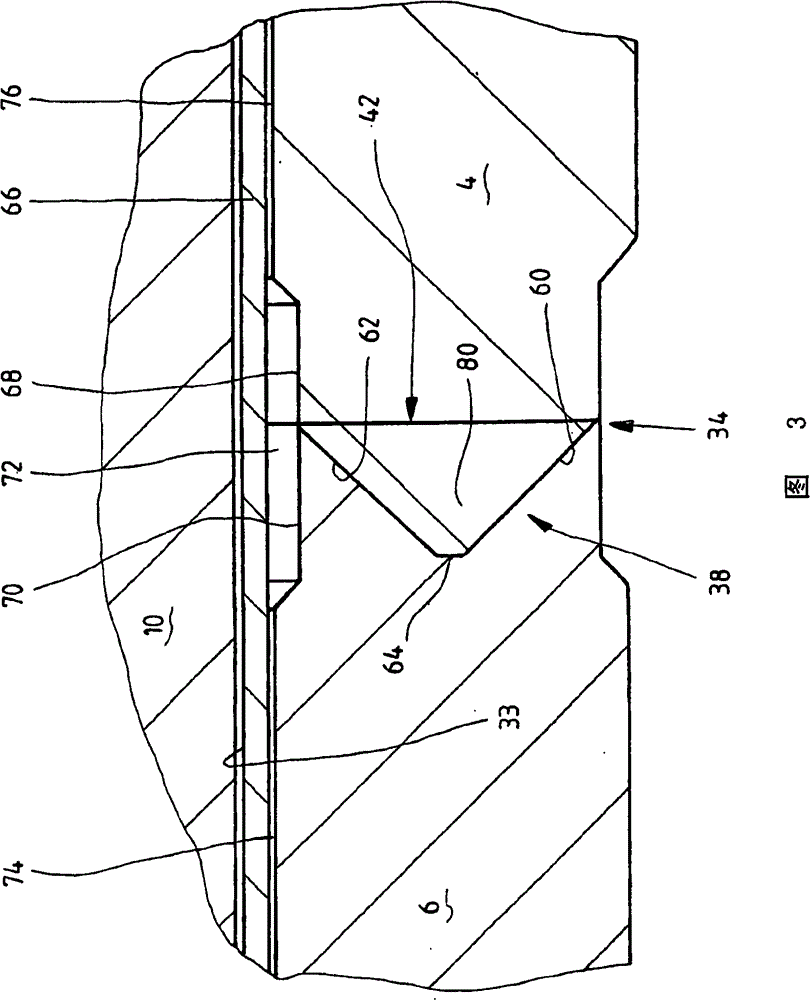

[0018] figure 1 A longitudinal section through a pole tube 1 of a simple-acting lift magnet in a pressure-tight design is shown. The pole tube essentially consists of a pole piece 2 , an intermediate piece 4 and a tube piece 6 , which are connected to one another by a thermal joining method, in the exemplary embodiment shown by capacitive discharge welding (KES). These three components together form the armature cavity 8 . In this cavity, the armature 10 of the lift magnet is guided axially displaceably. The plunger 12 is fixedly or detachably mounted on the armature 10 . This plunger passes through the pole piece 2 in the axial direction and serves to actuate the control slide of the valve to be actuated by the lift magnet.

[0019] pole shoe 2 in it's in figure 1 The right-hand end section shown in has a central thread 14 . With this central thread, the pole piece can be screwed into the valve bore of the valve housing, so that the operative connection of the plunger 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com