Thin paper winding apparatus having reverse poking mechanism

A reverse, paper roll technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of thin paper breakage, insufficient speed difference, and inability to absorb thin paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

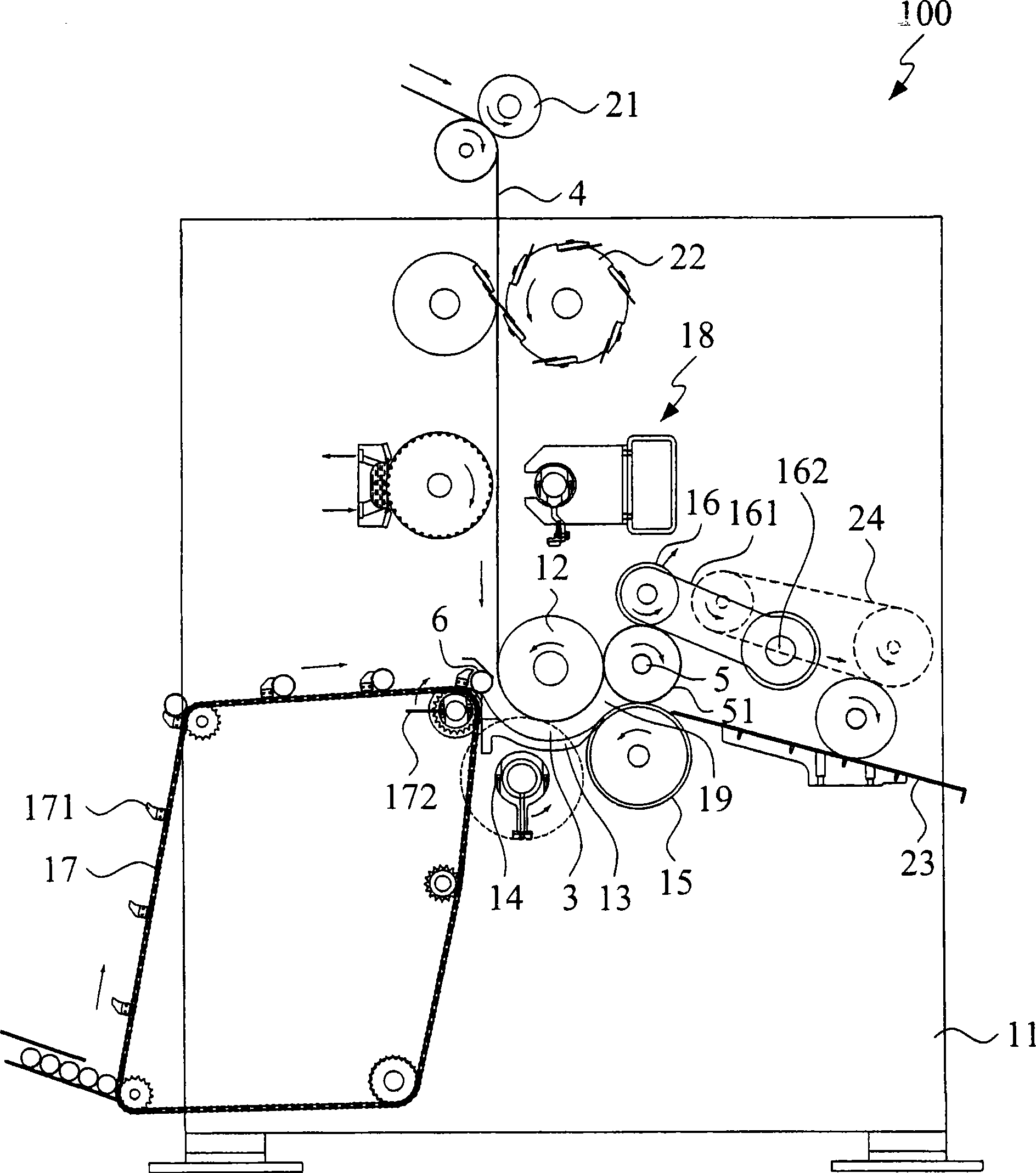

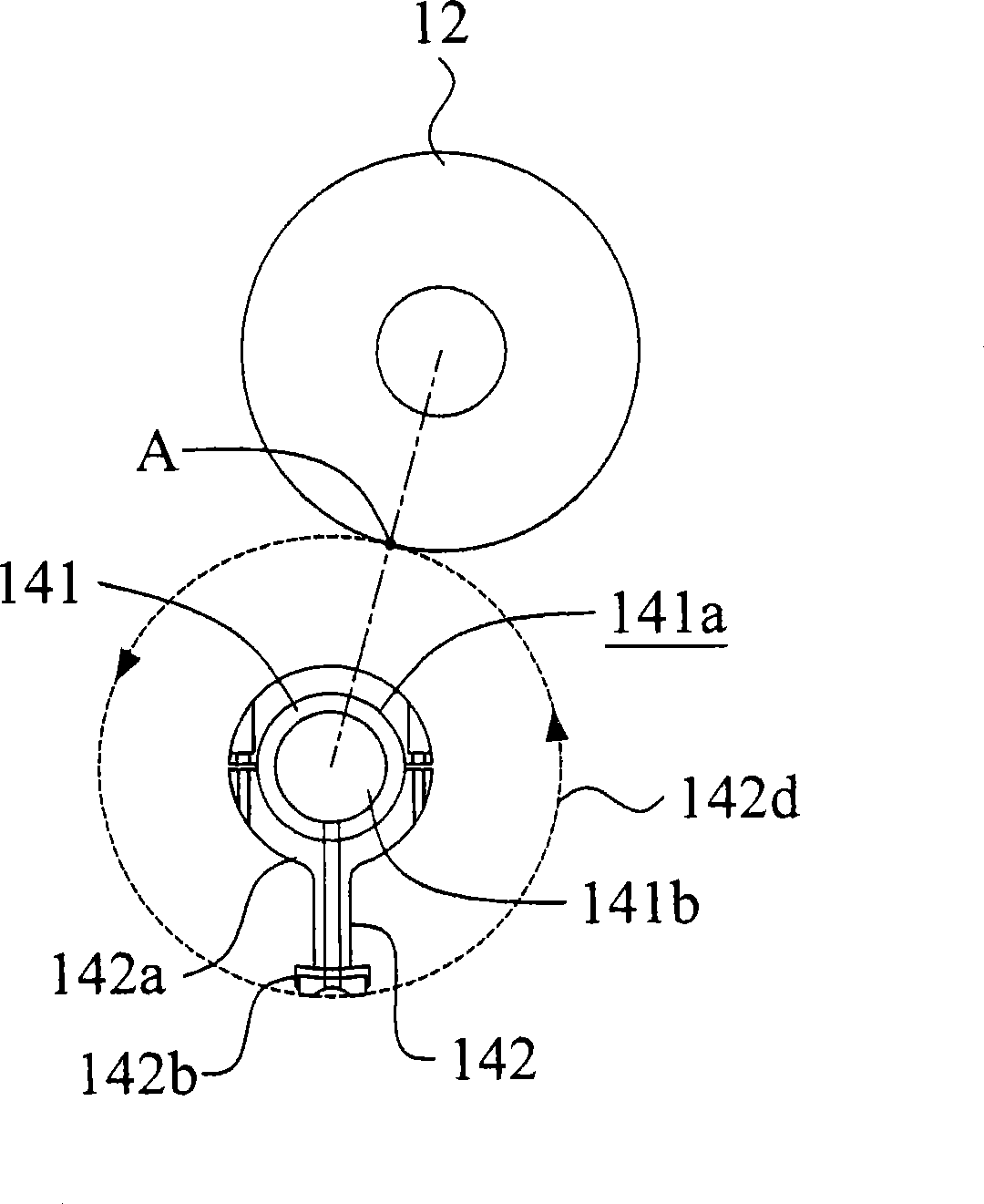

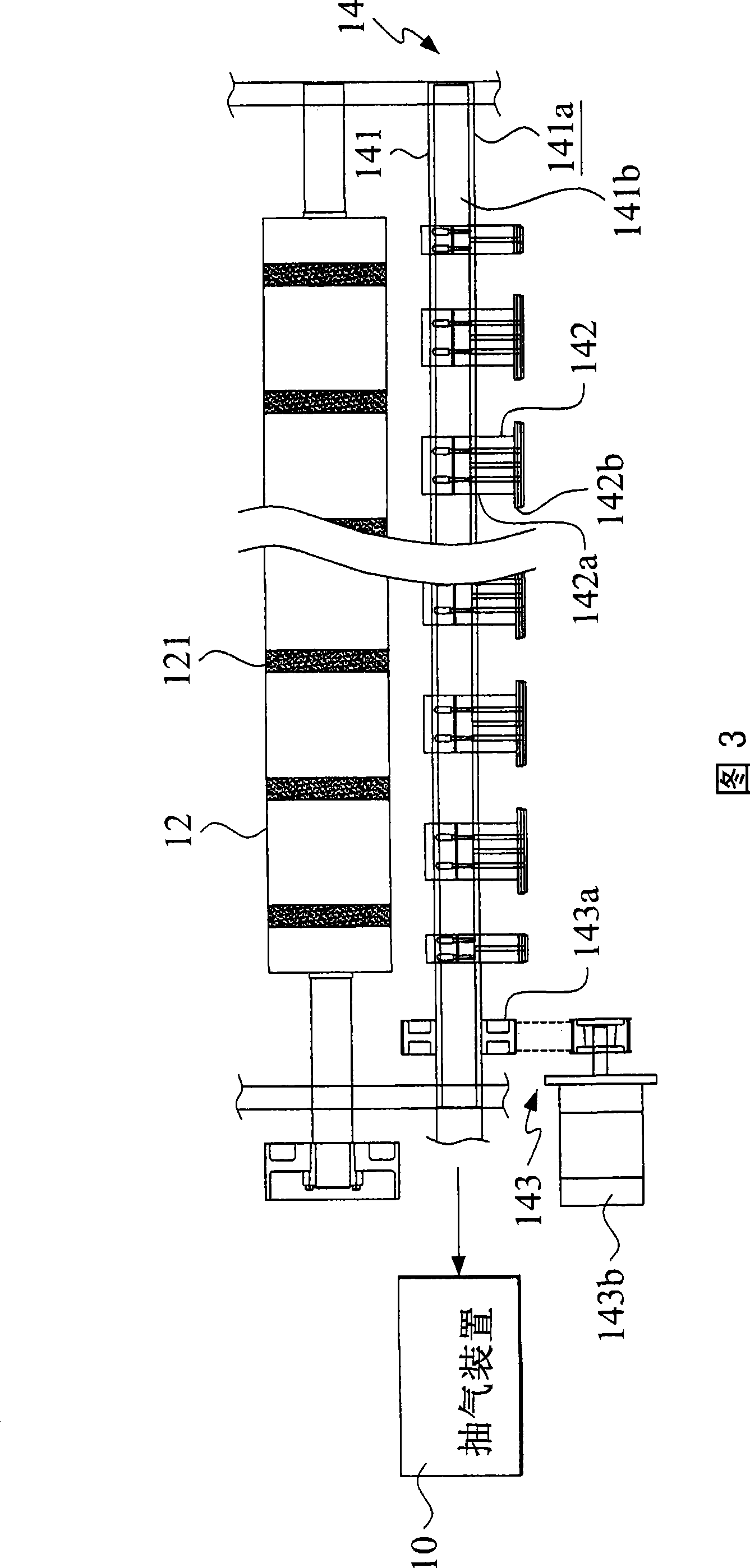

[0073] refer to figure 1 As shown, the first embodiment 100 of the tissue paper winding device with reverse dial-off mechanism of the present invention includes a base 11, a winding wheel 12, and a plurality of guide plates 13 (only one can be seen in the side view) , a reverse pull-off mechanism 14, a roll wheel 15, a riding wheel 16, a paper tube conveying device 17, a gluing mechanism 18, a pair of pinch wheels 21, a punching device 22, an inclined passage 23 and One compresses the conveyor belt 24.

[0074] The guide plate 13 is arranged at a position adjacent to the lower side of the winding wheel 12 and forms a channel 3 with the winding wheel 12 . A winding area 19 is formed between the upper winding wheel 12 , the lower winding wheel 15 and the riding wheel 16 . A thin paper 4 with a predetermined thickness and width is conveyed via the pinch wheel 21, and a row of holes is punched at a predetermined distance through the punching device 22, and then a tail glue and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com