Bird nest removing mechanism

A bird's nest and machine head technology, applied in the field of sewing machines, can solve problems such as increased production costs, and achieve the effects of convenient debugging, improved stability, and stable thread hooking and thread pulling processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

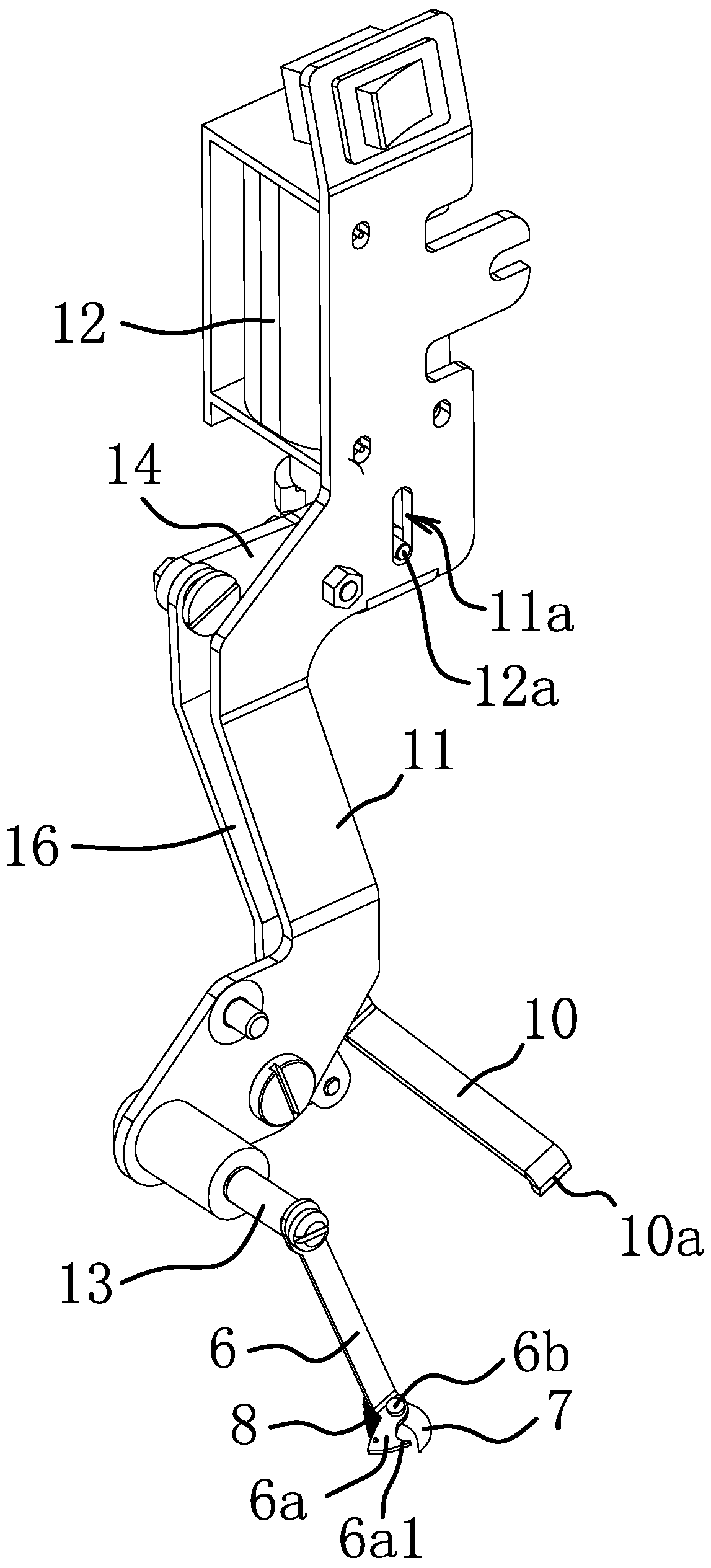

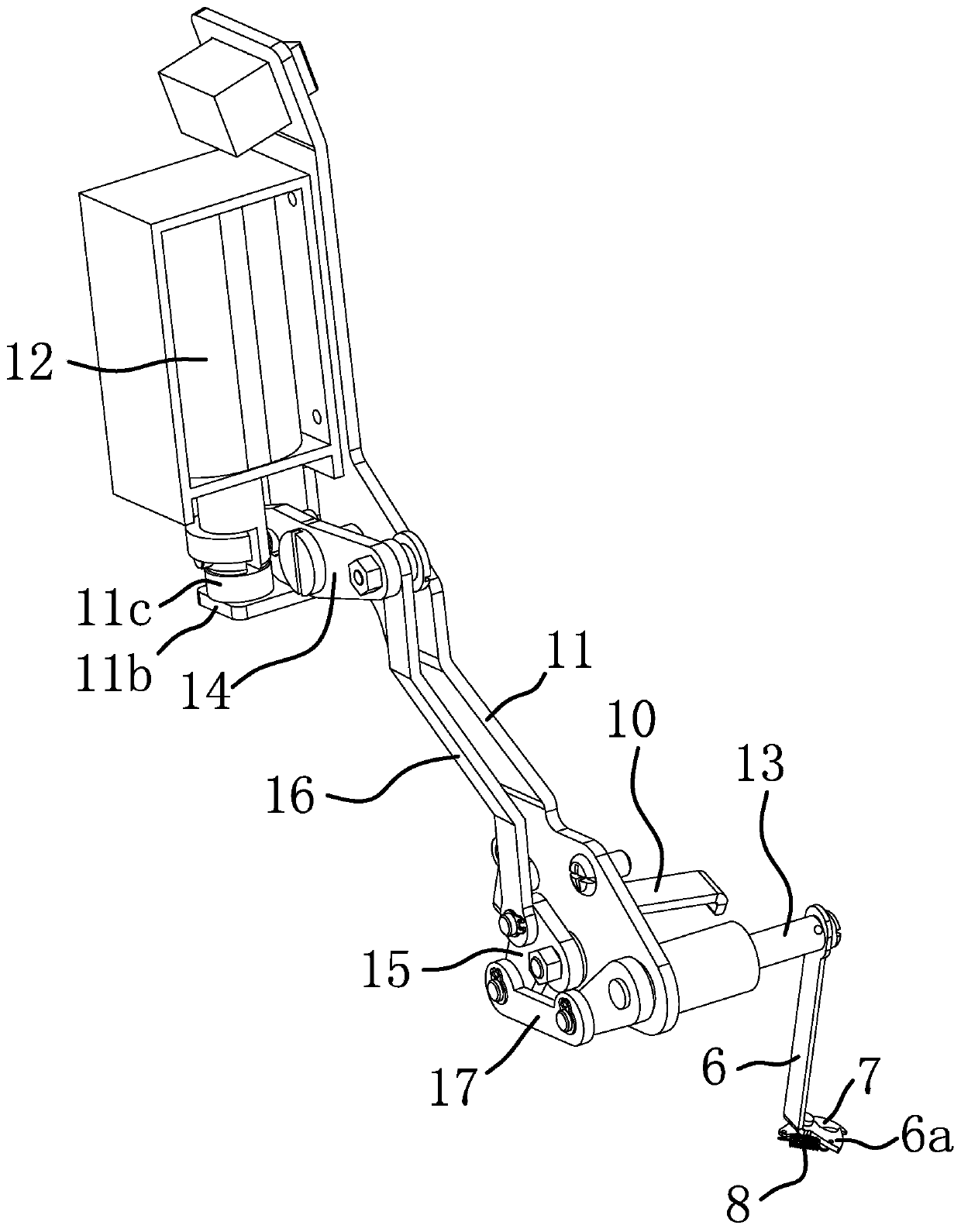

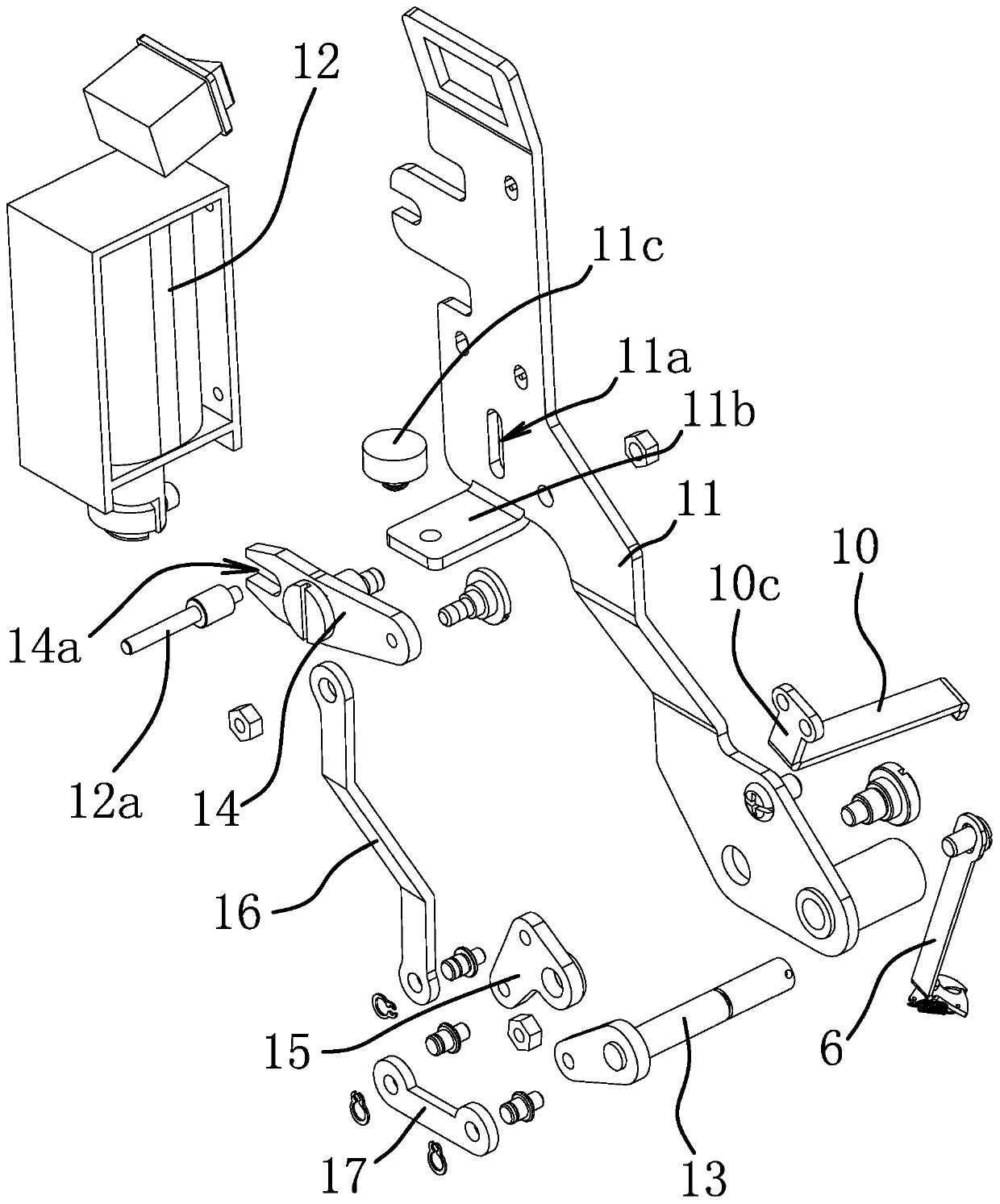

[0039] Such as Figure 1-Figure 8 As shown, the sewing machine includes a machine head 1 and a base 2. A machine needle 3 and a presser foot 4 are installed on the machine head 1 of the sewing machine. A suture 5 is threaded on the machine needle 3. The presser foot 4 is a presser foot with a knife, and the presser foot 4 The structure can refer to the patent document whose announcement number is: CN206873070U. Feeding teeth are installed on the base 2, and the feeding teeth are set correspondingly to the presser feet 4.

[0040] A bird's nest removal mechanism, which is arranged at the machine head 1, and includes a wire pulling part 6, a fixing part 10 and a drive assembly, and the wire pulling part 6, the fixing part 10 and the driving assembly are all fixed on a mounting plate 11, and the mounting plate 11 is fixedly connected on the rear face of the machine head 1. The wire pulling member 6 is in the shape of a strip, and the lower end of the wire pulling member 6 is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com