Post forming bending mould of automobile front wind screen glass

A front windshield and secondary molding technology, which is applied in glass molding, glass reshaping, glass production, etc., can solve problems that affect the development progress of new products, affect production efficiency, and have large quality fluctuations, so as to overcome debugging The effect of long time, improving production efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

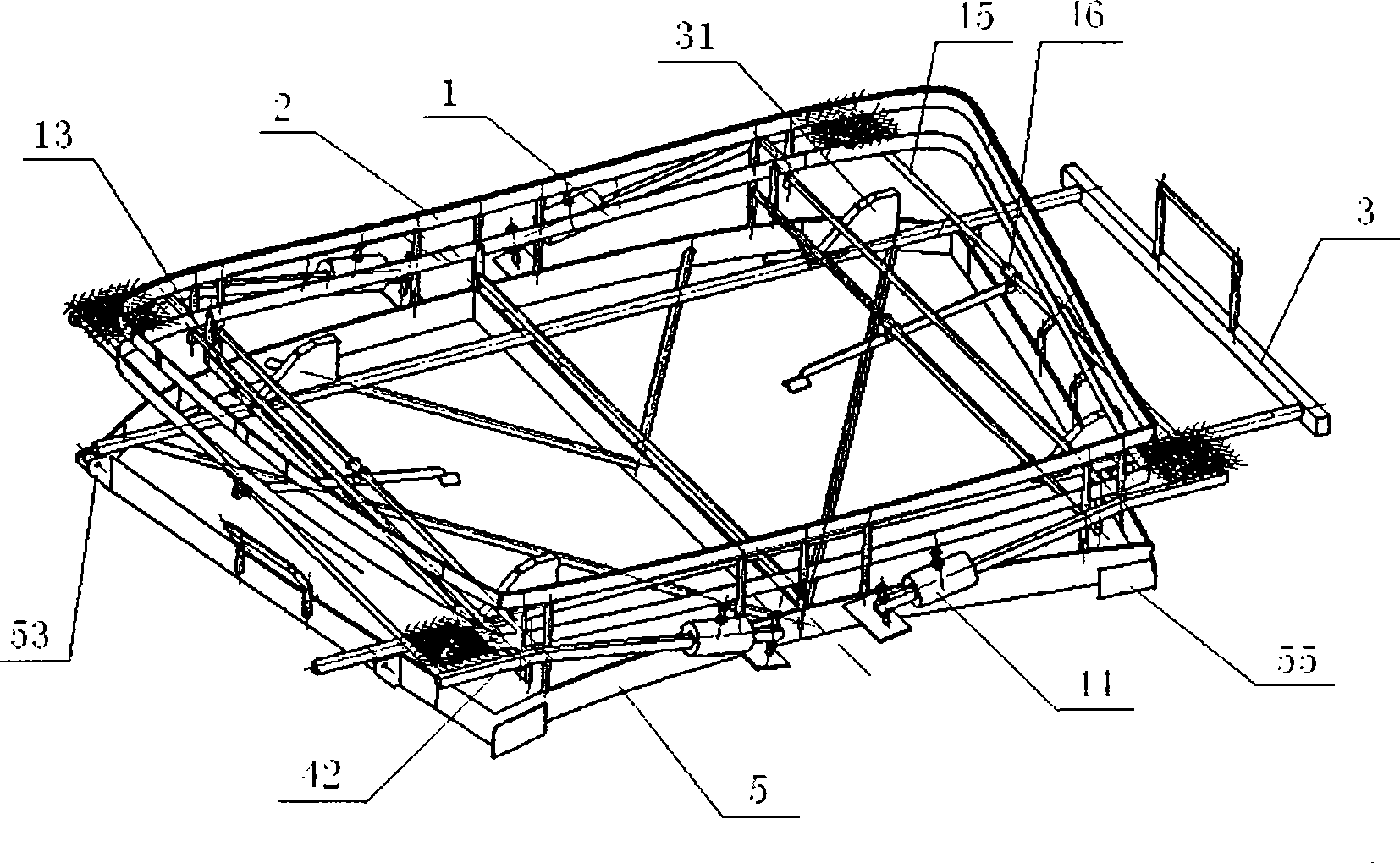

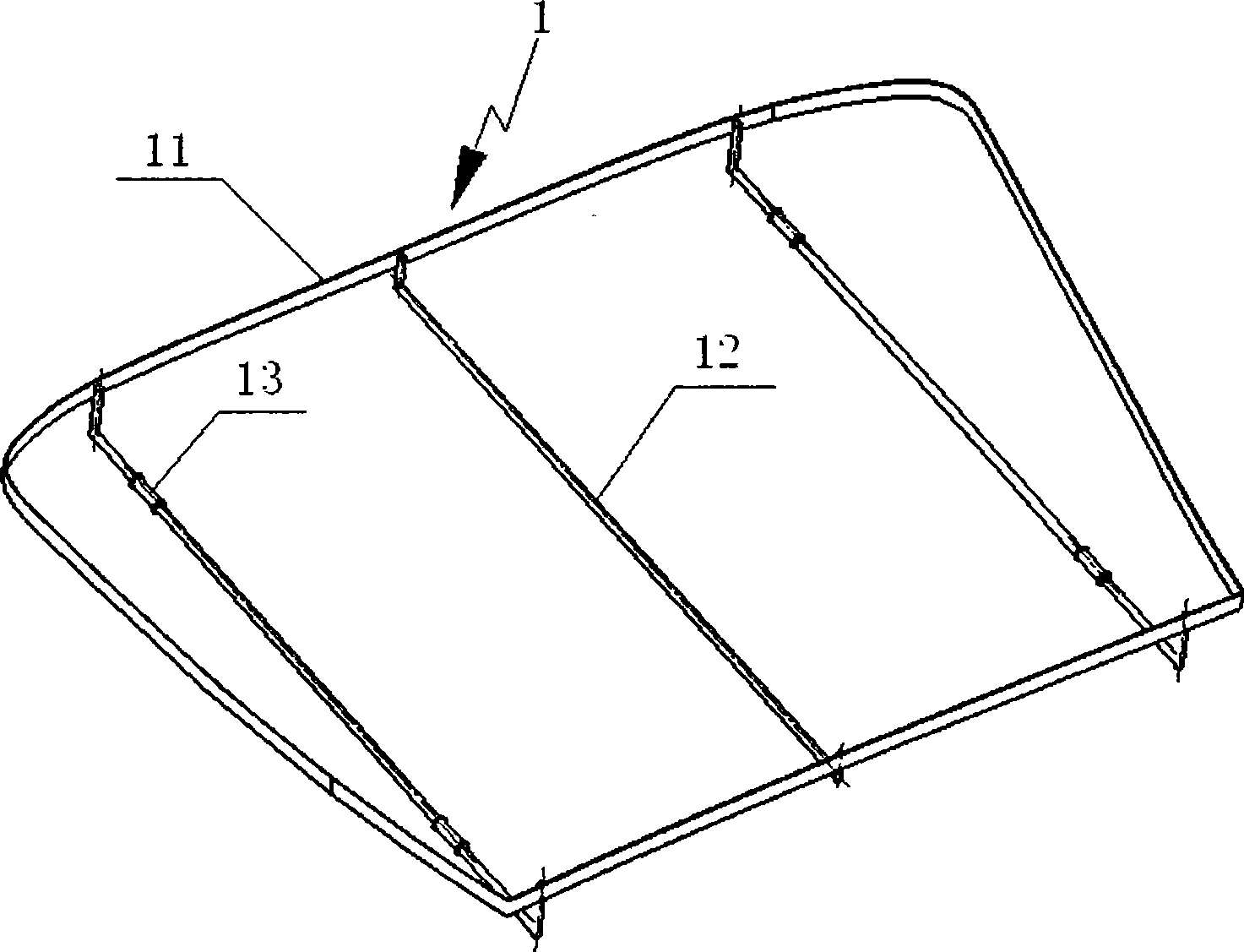

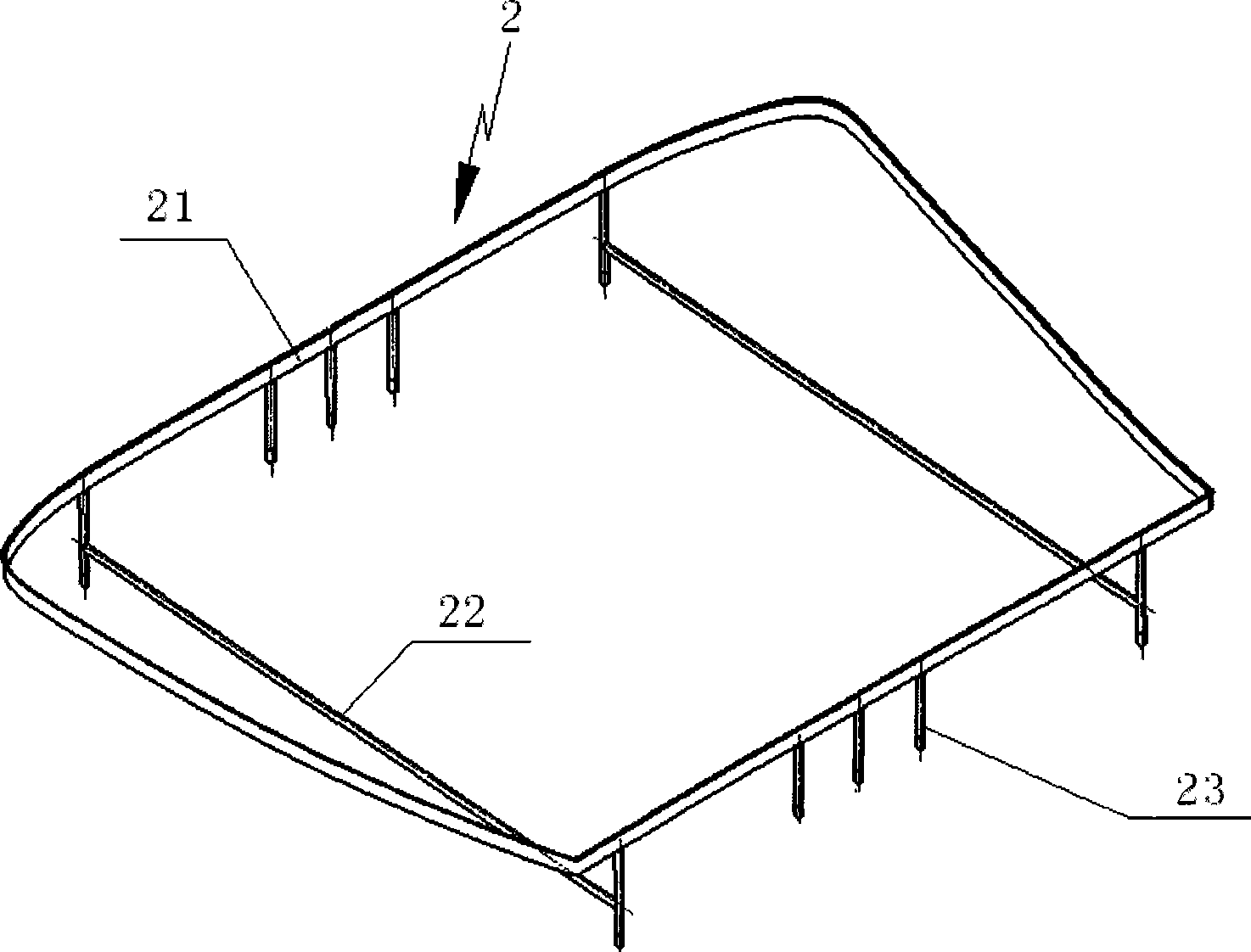

[0051]It is T3, a best-selling model of the French logo Citroen (PSA) facing the global market. It is very strict, with large radians on both sides and a relatively flat center. General baking and bending molds cannot meet its forming requirements. The present invention can improve this situation well by adopting two forming and bending molds: when the flat glass is placed on the mould, the movable inner frame is at the lowest position, and as the trolley enters the bending furnace, the temperature gradually rises, and the flat glass due to Under the action of gravity, the glass gradually deforms as it is heated. At this time, the forming of the middle of the glass is basically completed. When heated to about 500°C, the glass is in a softened state, and the forming temperature is optimal. At this time, under the action of the ejector pin, the inner frame rises steadily. Lift the glass up to make the glass completely fit the inner frame, and finally cool to complete the final s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com