Limestone powder dry powder mortar

A dry powder mortar and stone powder technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as insufficient supply of medium sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

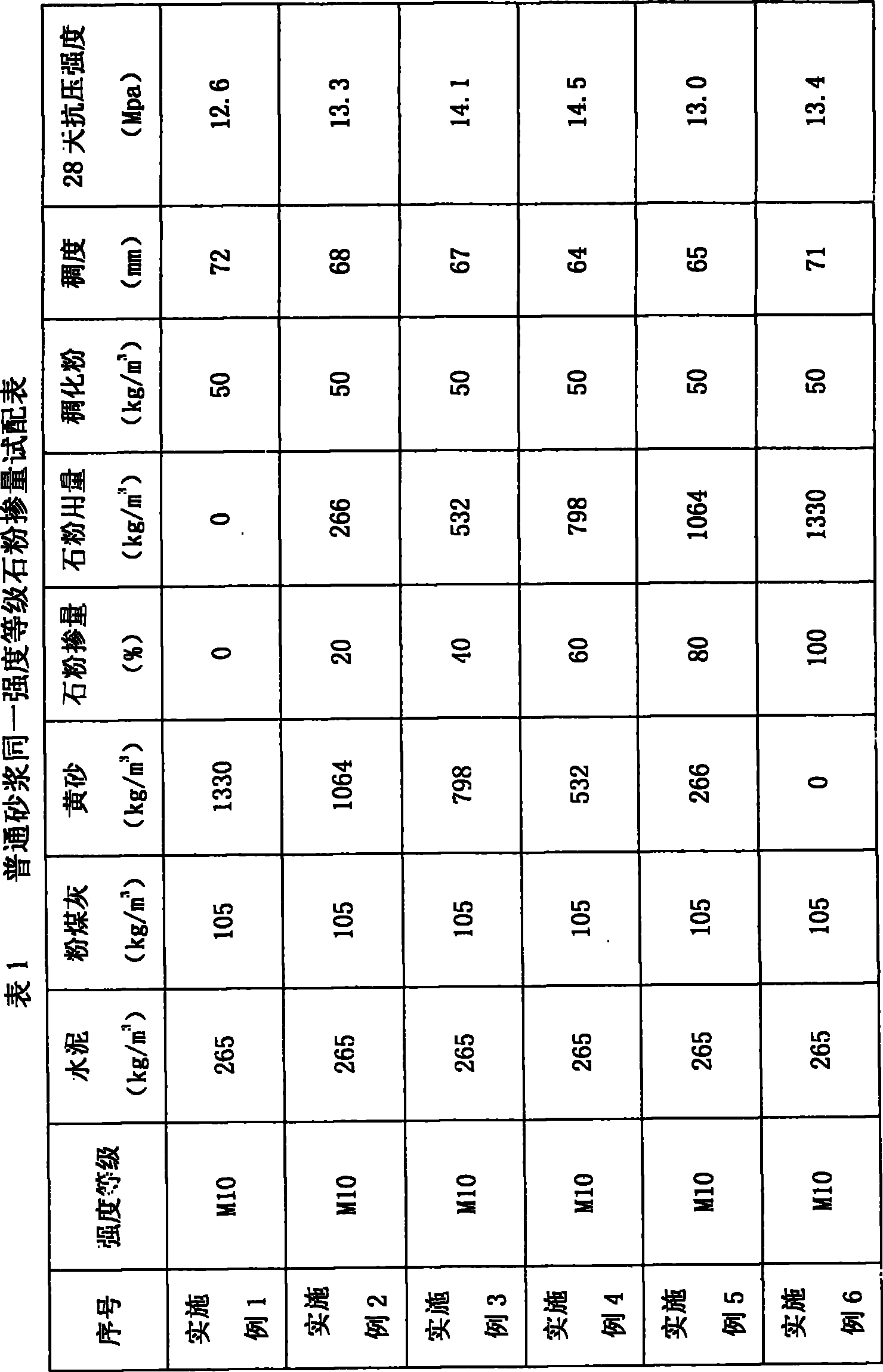

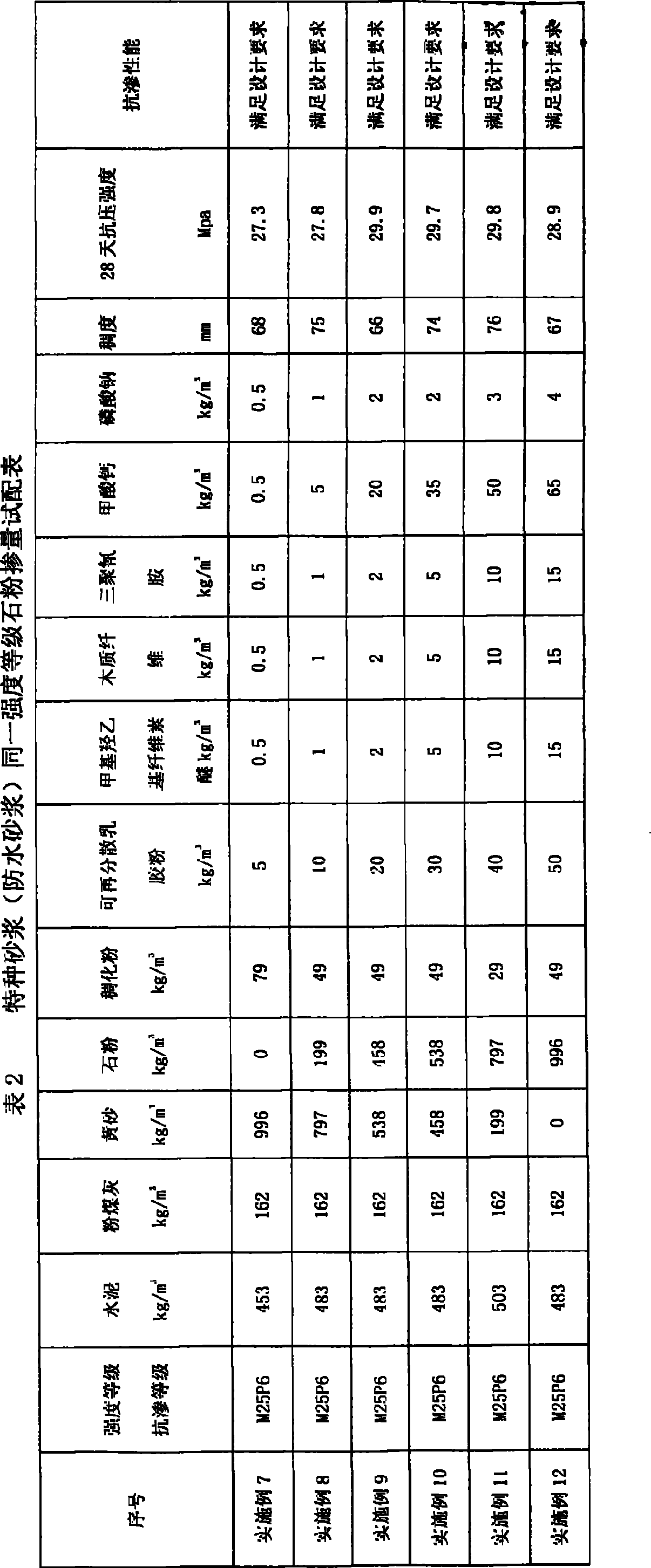

[0028] Embodiments 1-12 Mix the various raw materials weighed in proportion, add about one-fifth of the total weight of water and stir evenly.

[0029] The fineness modulus of yellow sand is 2.7-3.0, and it is medium sand in the second zone. The fineness modulus of stone powder is between 2.7 and 3.0, and it is graded in the second zone.

[0030] Results: From the test results of 12 ratios in Table 1 and Table 2, it can be seen that the strength is not greatly affected by the increasing amount of stone powder.

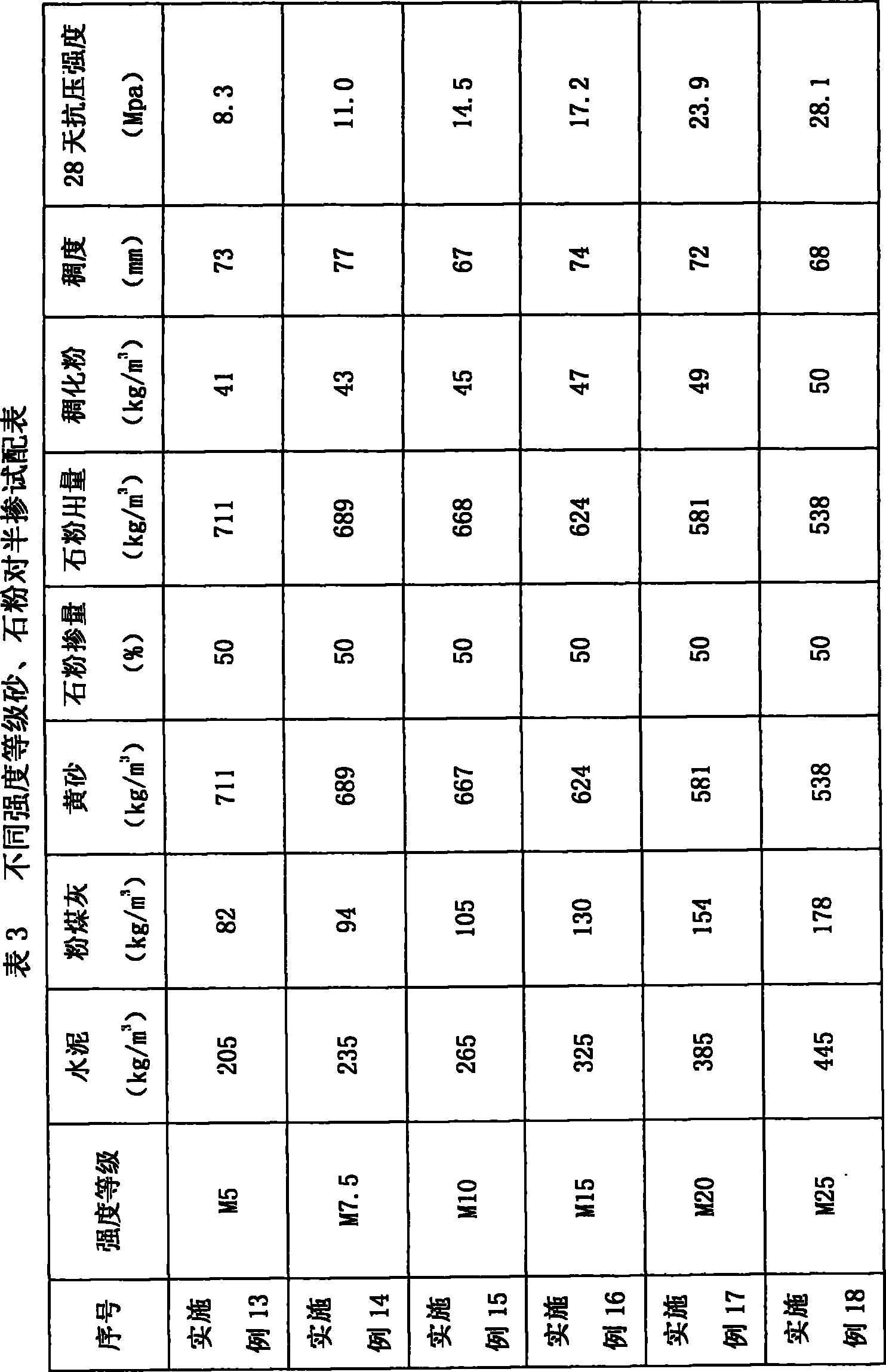

[0031] Examples 13-18 Mix the various raw materials weighed in proportion, add water about one-fifth of the weight of the total material and stir evenly. The fineness modulus of the yellow sand used is 2.8, which is medium sand in the second zone. The fineness modulus of stone powder is 2.9, and it is graded in the second zone.

[0032] Results: Through the comparison of Table 3 and Table 4, it is a group of 6 ordinary mortars with different strength grades for tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com