Method for lighting ultra-long shafting on marine vehicle to center

An ultra-long axis and lighting technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems that observers cannot accurately aim at the target image, it is difficult to meet the precision requirements of shipbuilding, and large precision errors, etc., to achieve accurate and fast Alignment, solve the problem of centering, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

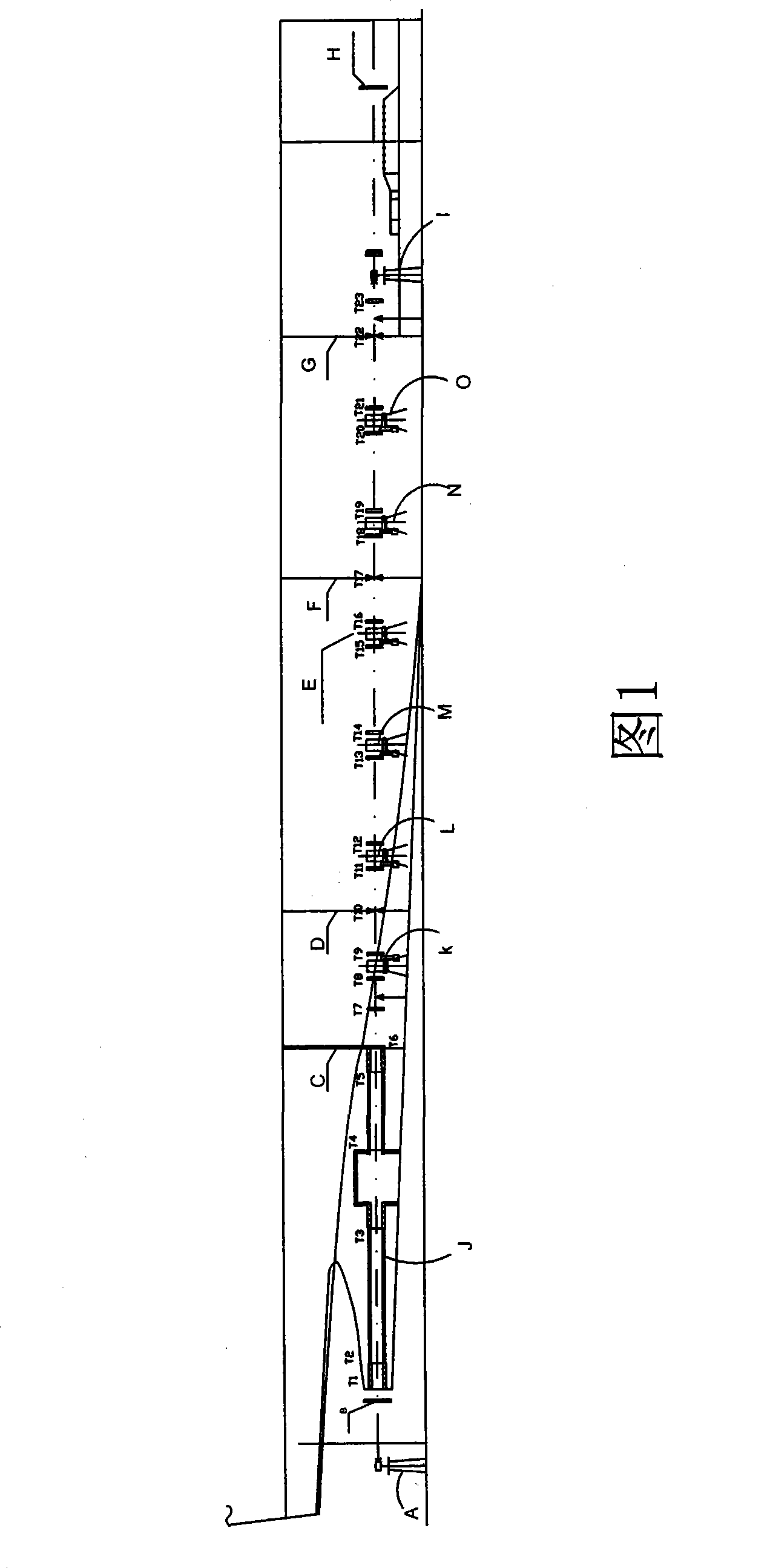

[0041]In this embodiment, the length of the ultra-long shafting of a large ship is about 90m, and 23 illumination targets will be arranged on the entire axis. The specific arrangement is shown in Figure 1, which is a schematic diagram of the distribution of light targets on a ship in an embodiment of the present invention. It can be seen from the figure that a total of 23 lighting targets T1~T23 are arranged on the shafting of a large ship with a length of about 90M: among them, T1~T6 lighting targets are set on the stern tube J; the six bearing seats in the middle each A lighting target is set on each side of each bearing seat: the two sides of the first bearing seat K are T8 lighting target and T9 lighting target, the two sides of the second bearing seat L are T11 lighting target and T12 lighting target, and the third bearing seat The two sides of M are T13 lighting target and T14 lighting target, the two sides of the fourth bearing seat E are T15 lighting target and T16 lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com