Making an elongated product

一种产品、细长的技术,应用在制造细长产品领域,能够解决难以确保芯和金属包层附着、技术方案复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

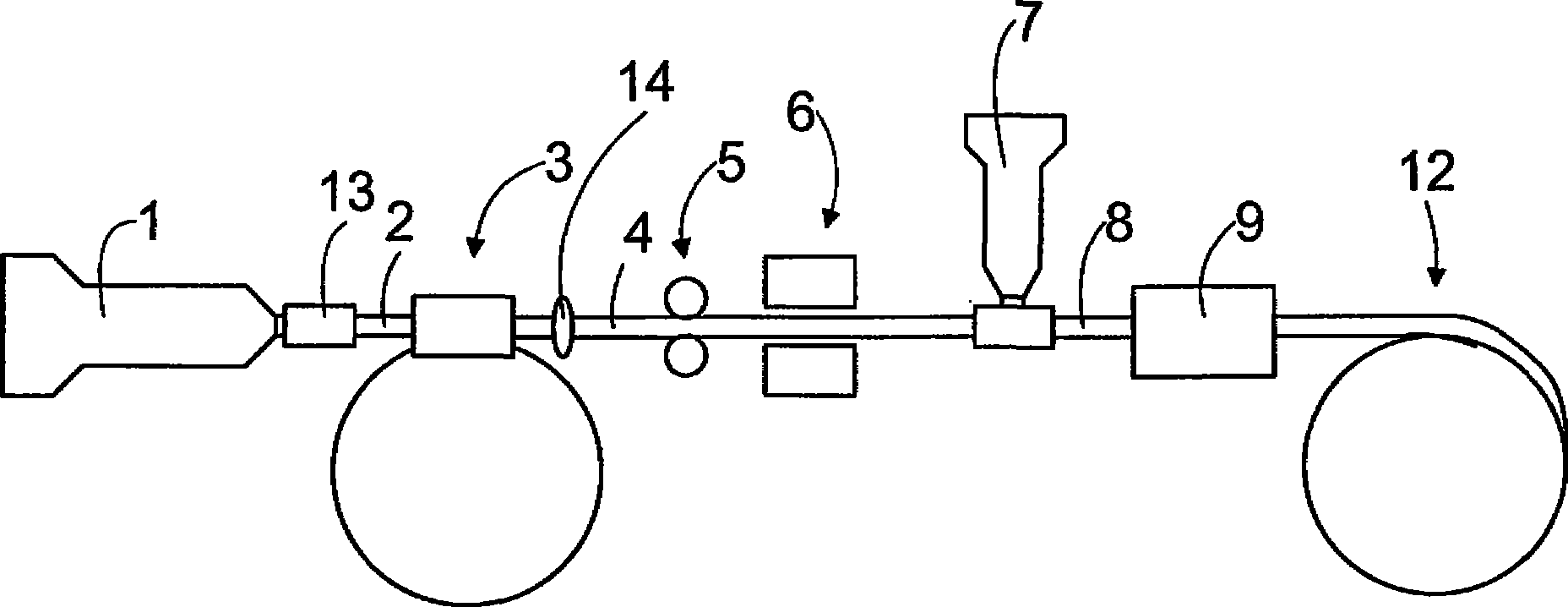

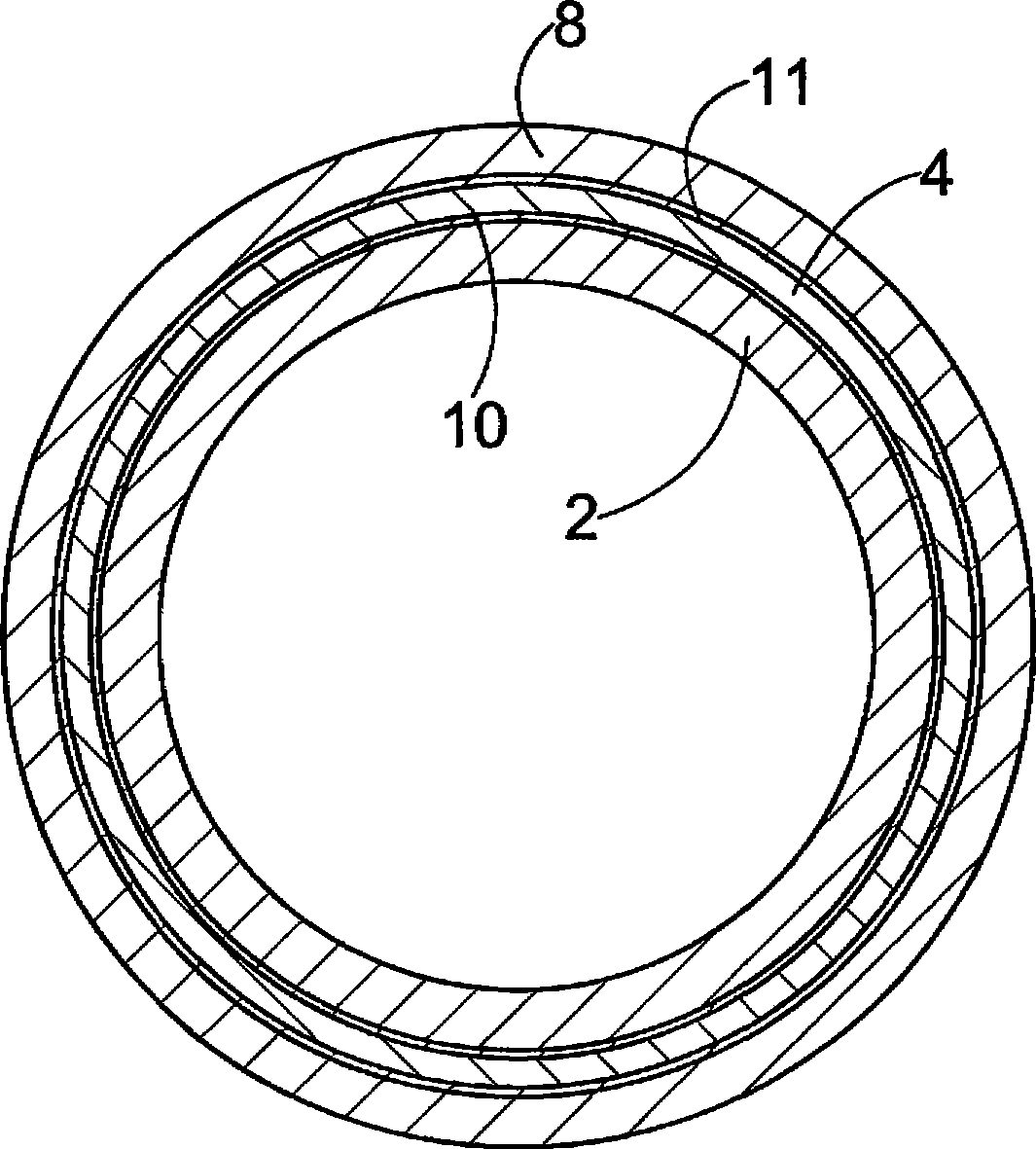

[0017] figure 1 It is disclosed how to form a multilayer composite pipe with seamless aluminum layers between plastic layers. figure 2 An example of such a tube is shown.

[0018] Firstly, the inner layer 2 of the tube is extruded using the first plastic extruder 1 . The inner layer 2 forms the die. After the first plastic extruder there is a calibration / cooling pool 13 . The inner layer 2 is coated with a tie layer. Thus, in the formed tube there is an inner bonding layer 10 between the inner layer 2 and the aluminum layer 4 . The inner bonding layer 10 and the inner layer 2 can be co-extruded. If the inner layer 2 is made of a high molecular weight plastic which itself has good adhesion properties, for example due to grafted functional end groups, then no tie layer is required.

[0019] The inner layer can be extruded from polyethylene PE, cross-linked polyethylene PEX, polypropylene PP or polybutylene-1PB, for example. The tie layer may comprise, for example, polyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com