Printer

A technology for printing presses and printing paper, applied in printing presses, printing, rotary printing presses, etc., can solve the problems of long operation time, difficult operation, and heavy burden on operators, and achieve the effect of easy replacement operation and easy maintenance operation.

Inactive Publication Date: 2010-11-10

MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when changing the blanket of a blanket cylinder, for example, if the blanket cylinder is stopped at a predetermined rotation angle using the constant-width button provided on the operation panel, the operator needs to operate the constant-width button while visually checking the rotational position of the blanket cylinder. The button rotates the rubber cylinder at a small angle every time, which makes the operation more troublesome, not only increases the operation time, but also increases the burden on the operator

On the other hand, during the oiling operation of the intermediate cylinder and the impression cylinder, when each cylinder stops at a predetermined rotation angle, the oiling position of the intermediate cylinder and the impression cylinder is at a position covered by the cover, and the operator It is impossible to operate the operation button while visually observing the rotation position of each drum, but to predict the stop position and operate the button based on the operator's experience, the work becomes difficult and the work time becomes longer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

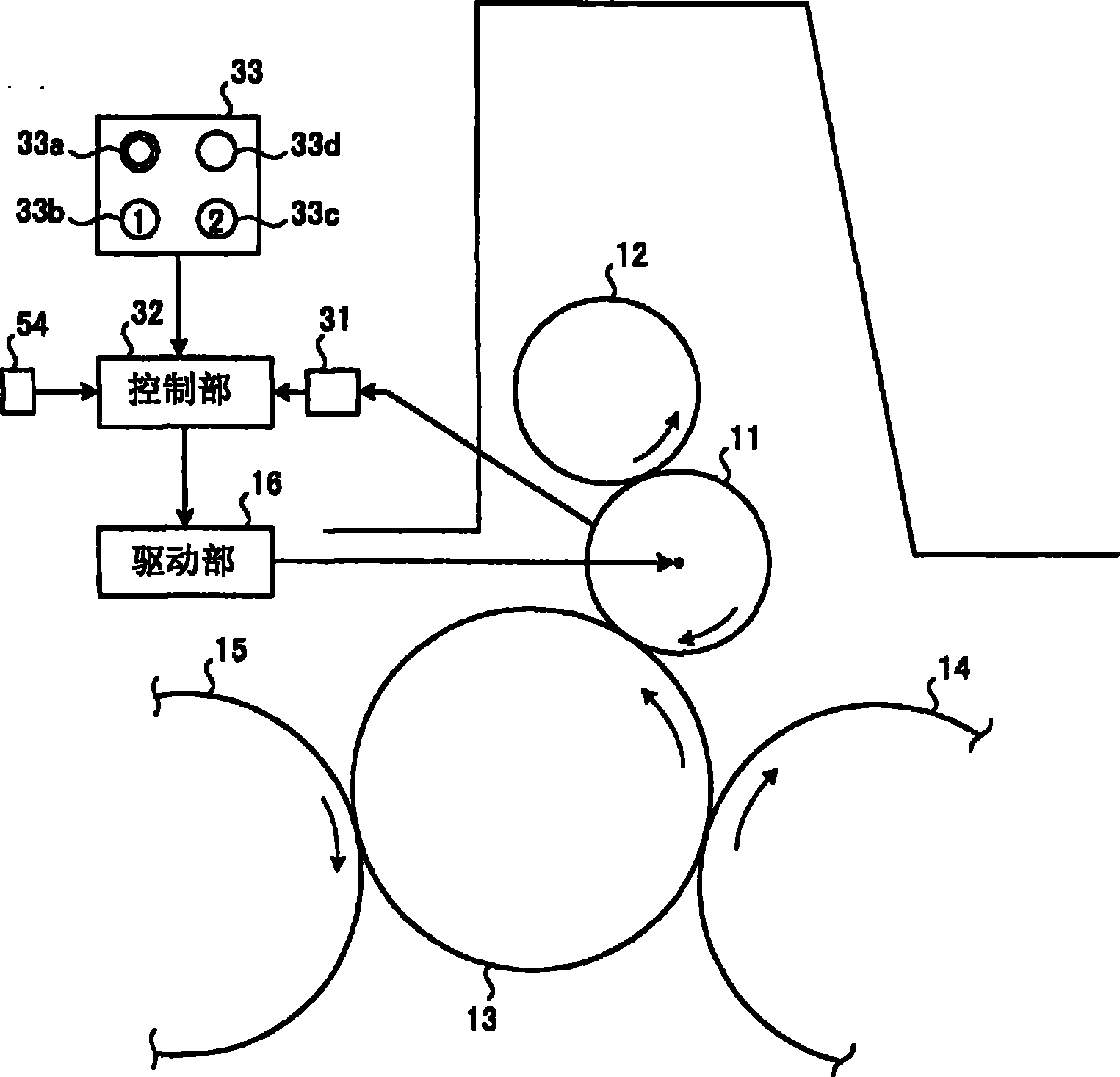

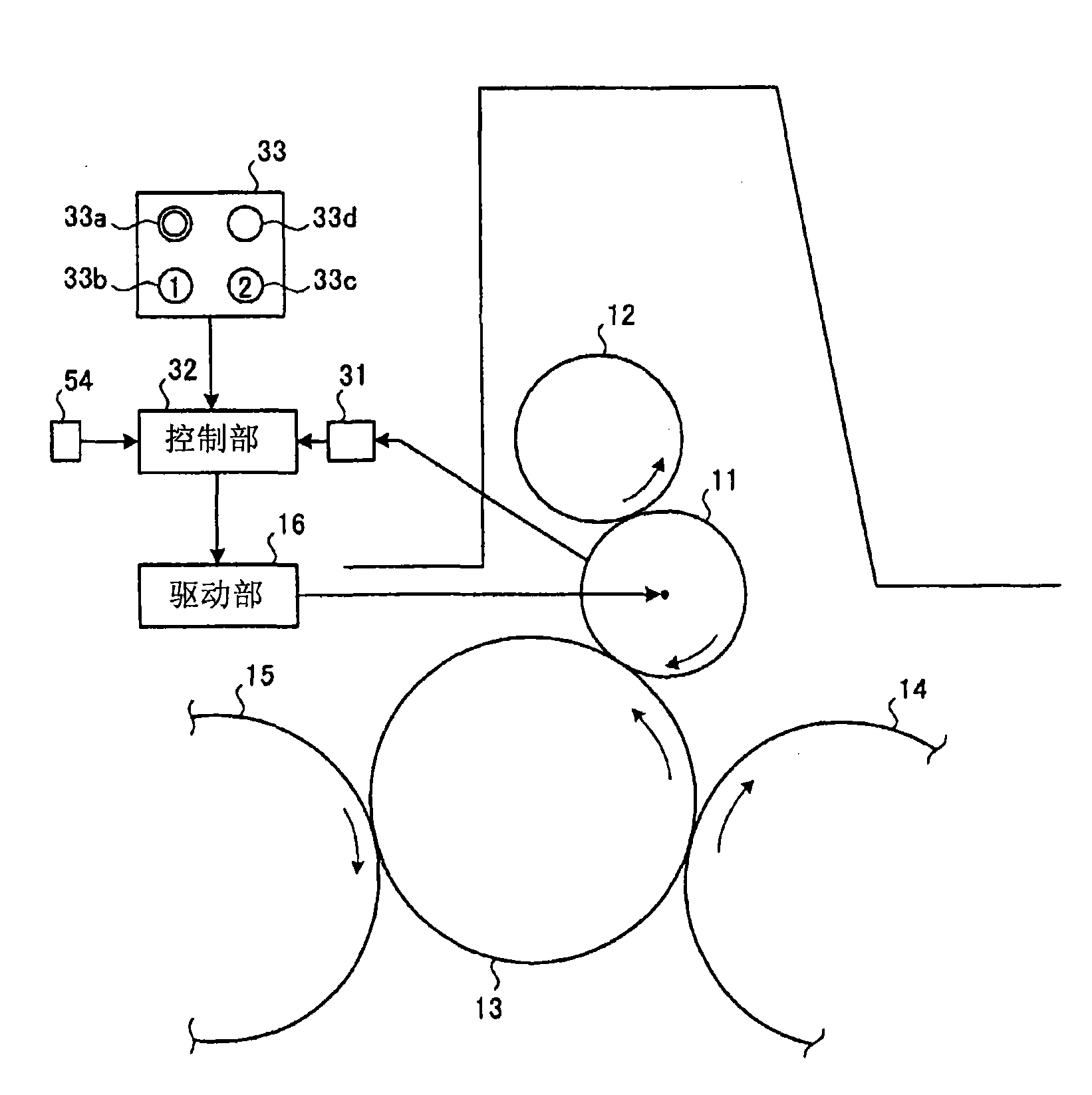

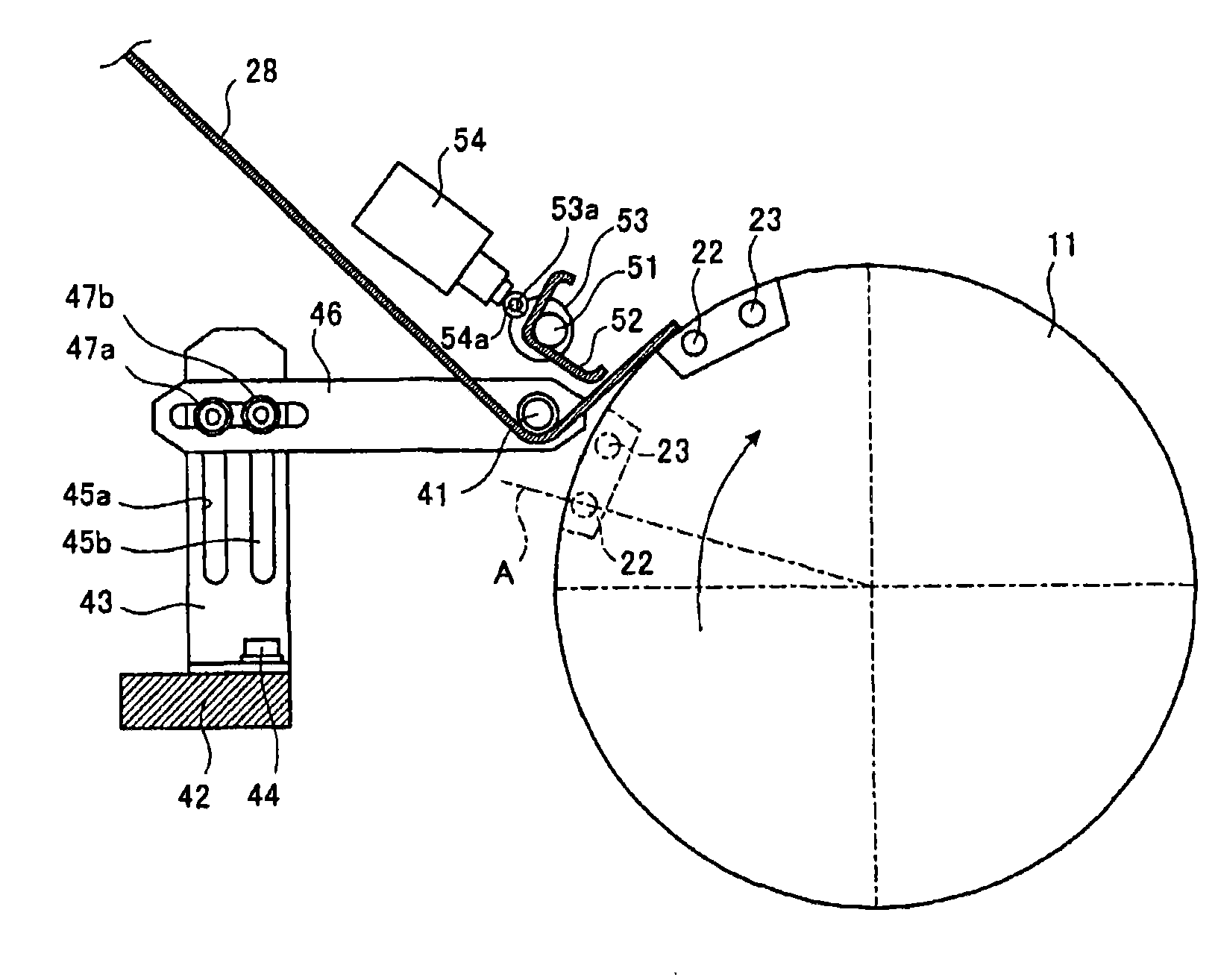

A printing press is configured such that the printing sheet is supplied from the paper feeding unit through the intermediate cylinder 14 while the ink is supplied from the ink apparatus to the blanket cylinder 11 through the printing cylinder 12 and, when the printing sheet passes between the blanket cylinder 11 and the impression cylinder 13, the ink is transferred from the blanket cylinder 11 and, thereby, printing is executed. In the printing press, the rotary encoder 31 detects the rotation angle of the blanket cylinder 11 and the control unit 32 receives the instructions of the head portion finding switches 33b, 33c and drives and controls the driving unit 16 and, thereby, the blanket cylinder 11 can be rotated and stopped to / at the blanket replacement angle for replacing the blanket28 wound around the blanket cylinder 11.

Description

printing press technical field The present invention relates to a printing machine, which supplies printing paper from a paper feeder via an intermediate cylinder, and supplies ink from an ink unit to a blanket cylinder via a printing plate cylinder on the other hand, when the printing paper passes between the blanket cylinder and the impression cylinder, from Printing is performed by transferring ink from a blanket cylinder. Background technique In a general offset printing machine, printing units of multiple ink colors (such as cyan, magenta, yellow, black, and other special colors according to needs, etc.) are arranged along the conveying path of the printing paper, and each printing unit has an ink supply. device. Therefore, the ink whose supply amount is adjusted by each ink unit is supplied to the plate surface of the plate cylinder through the ink roller group, and the ink adhering to the plate is supplied to the rubber cylinder. When the printing paper passes betw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B41F33/08B41F30/00B41F27/12

CPCB41F13/0045B41F33/0009B41F33/08

Inventor 濑户一哲望月泰宏平田靖彦八木哉森本聪佐藤刚松浦义郎

Owner MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com