Sealed flange joint for high pressure and high purity gas channels

A technology for sealing flanges and fluid passages. It is used in flange connections, pipe joints, and pipe connection arrangements. It can solve the problem that metal O-rings are not suitable for detachable connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

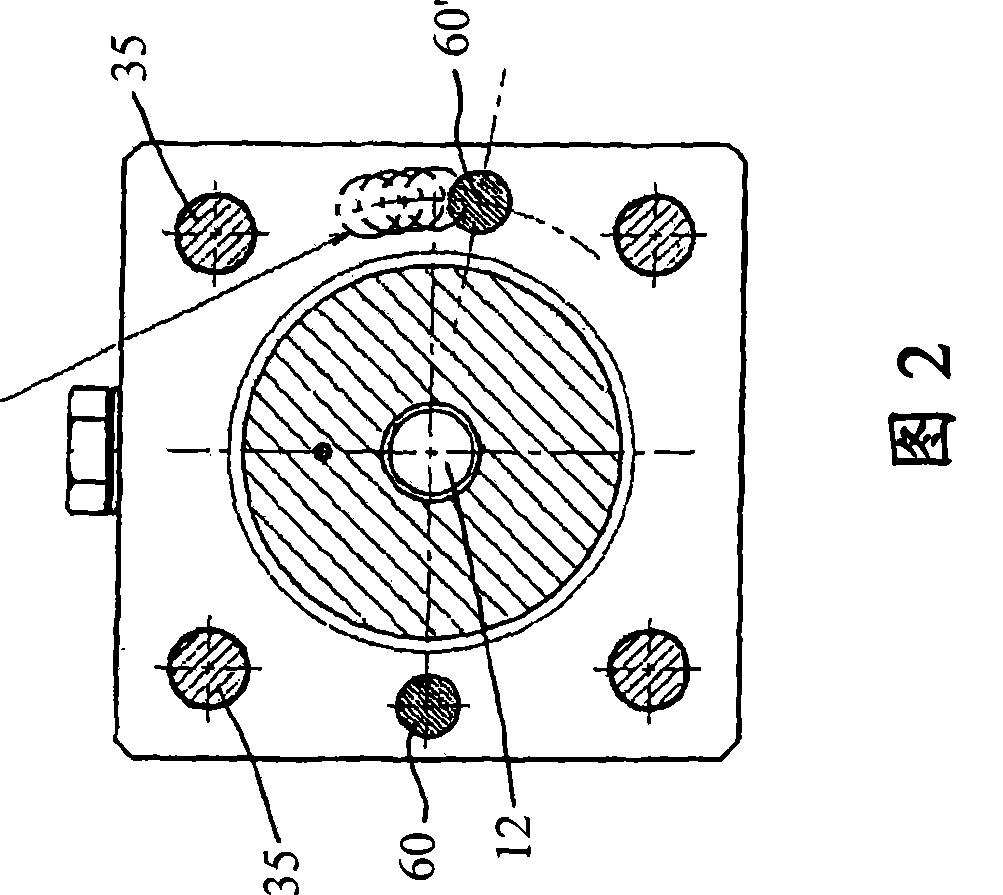

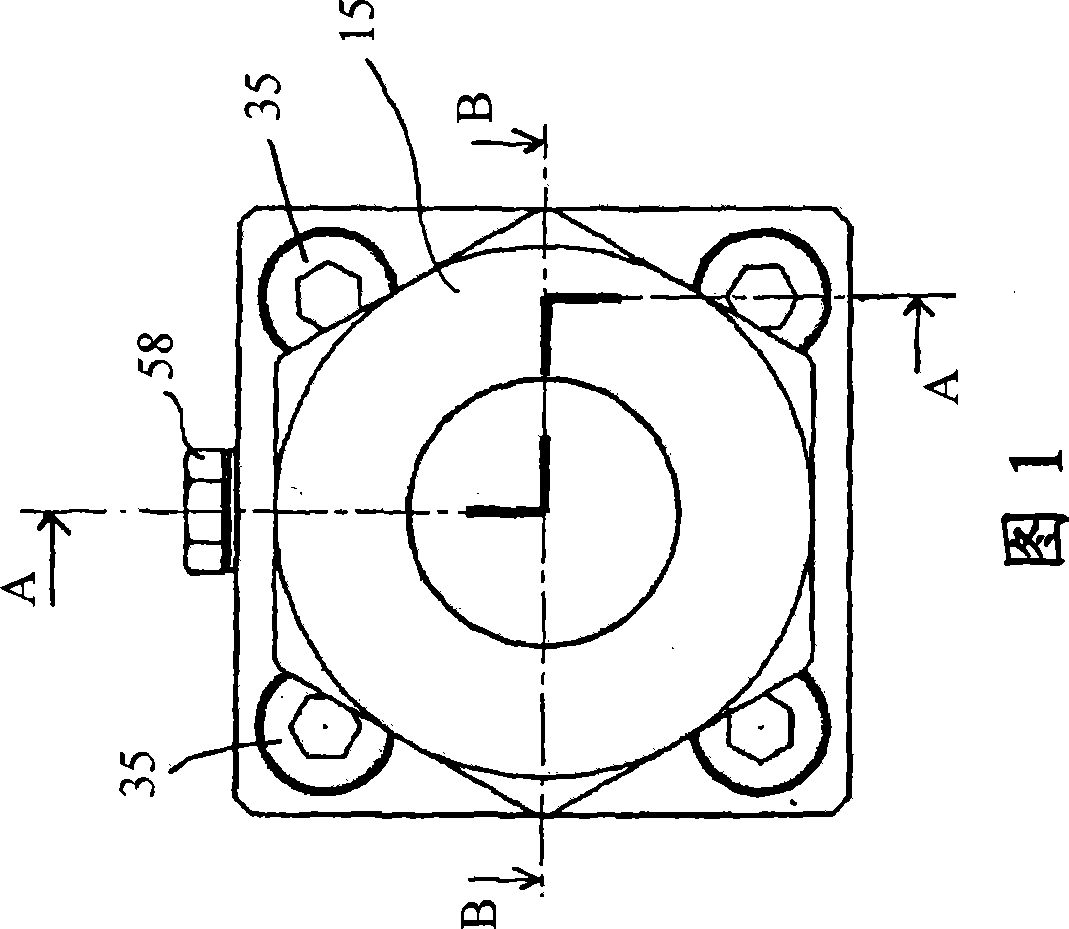

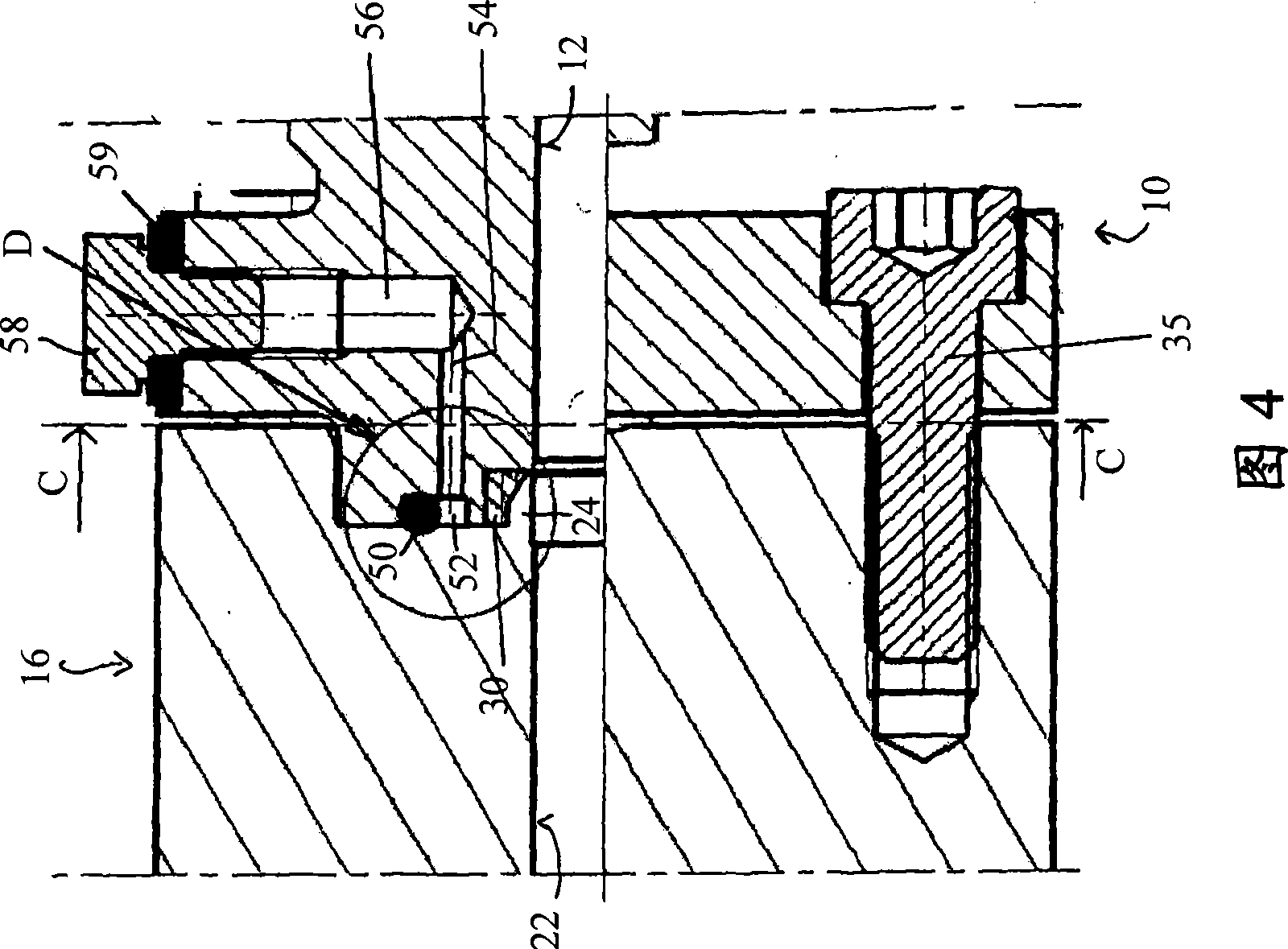

[0034] The figures show a preferred embodiment of a sealed flange joint according to the invention. As will be shown below, a sealed flange joint involves the fitting of a pair of flanges in a sealed manner. This flange joint design can be used as a variety of sealed connections in fluid (especially gas) passages and any fluid / gas containment, processing or distribution systems, such as between gas cylinder valve ports and delivery pipes. This type of flanged joint is especially suitable for applications using ultra-pure, highly corrosive, and high-pressure gases.

[0035]Referring now to FIG. 3 , there is shown a first flange 10 having a first gas passage 12 and a gas collector front cavity 14 . This first flange 10 can be arranged, for example, at the end of the conveying pipe 15 . Reference numeral 16 generally designates a second flange, the two flanges 10 and 16 being detachably secured to each other as will be further explained below. Such a second flange structure ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com