Image forming method and electronic photographing device using the same

A technology of image and shape factor, applied in electrography, instrument, developer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0384]Non-magnetic toner 1 and carrier 1 were blended at a toner concentration of 8%, thereby forming two-component developer No. 1.

[0385] Next, the electrophotographic photosensitive member 1 was assembled into a remodeled machine of an electrophotographic copier iRC6800 manufactured by CANON INC. (remodeled into a negative charging type) to be evaluated in the following manner.

[0386] First, under the environment of temperature 23° C. / humidity 50% RH, the condition of the potential is set so that the electrophotographic photosensitive member has a dark potential (Vd) of −700 V and a bright potential (Vl) of −200 V, and the electrons are adjusted. The initial potential of a photographic photosensitive member.

[0387] Next, a cleaning blade made of urethane rubber was set at a contact angle of 26 degrees with respect to the surface of the electrophotographic photosensitive member and a contact pressure of 0.294 N / cm (30 g / cm).

[0388] Then, using the above developer No...

Embodiment 2

[0411] An image reproduction test was performed in the same manner as in Example 1 except that the photosensitive member and developer used for image reproduction were changed as shown in Table 3. In addition, evaluation was performed in the same manner as in Example 1.

[0412] In the image forming method of this example, good cleaning performance was exhibited in low-density test chart reproduction, but line reproducibility in high-density test chart reproduction was inferior to that in Example 1. However, the torque did not rise during the durability test, so no image defects occurred throughout the durability test. Dot reproducibility is also good in a high-temperature, high-humidity environment. The evaluation results are shown in Table 3.

Embodiment 3 to 22

[0414] An image reproduction test was performed in the same manner as in Example 1 except that the photosensitive member and developer used for image reproduction were changed as shown in Table 3. In addition, evaluation was performed in the same manner as in Example 1.

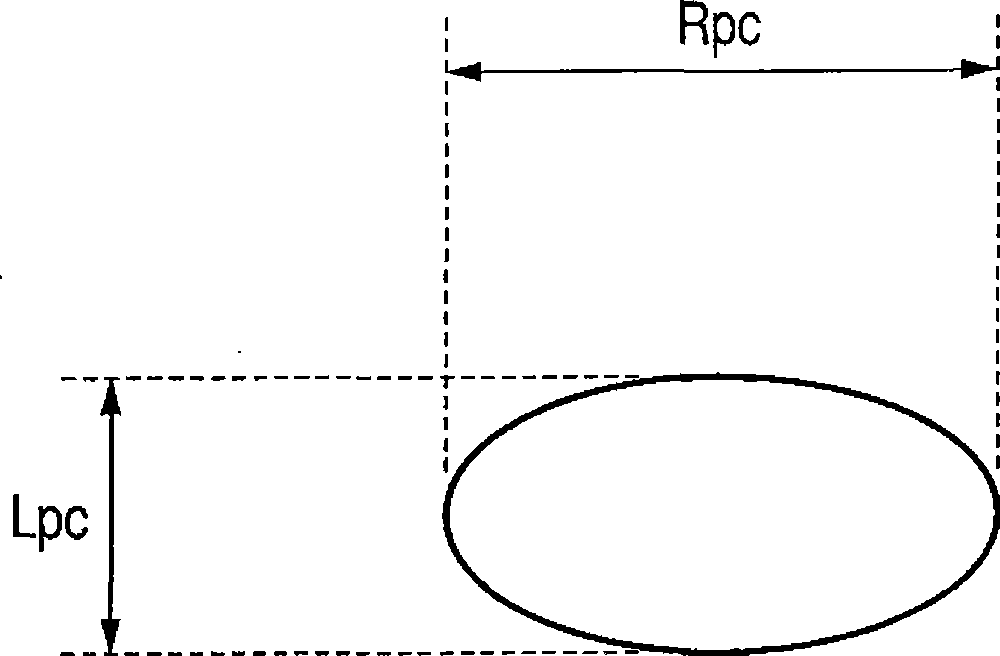

[0415] In the image forming methods of these Examples, it was seen that the line reproducibility in the reproduction of the high-density test chart was insufficient in some cases. In all cases, however, good cleaning performance was shown in the low concentration test chart reproduction. The evaluation results are shown in Table 3. Wherein the photosensitive member surface profile index K (K=tan -1 ((Epc-Epch) / Edv) as the abscissa and the toner average circularity as the ordinate are plotted to show the evaluation results of the line reproducibility in the reproduction of the high density test chart is shown in FIG. 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com