High-efficiency bottle cover arrangement machine

A bottle cap, high-efficiency technology, applied in the field of machinery, can solve the problems of long arrangement time, huge equipment, easy deformation of bottle caps and low efficiency, and achieves the effect of simple operation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

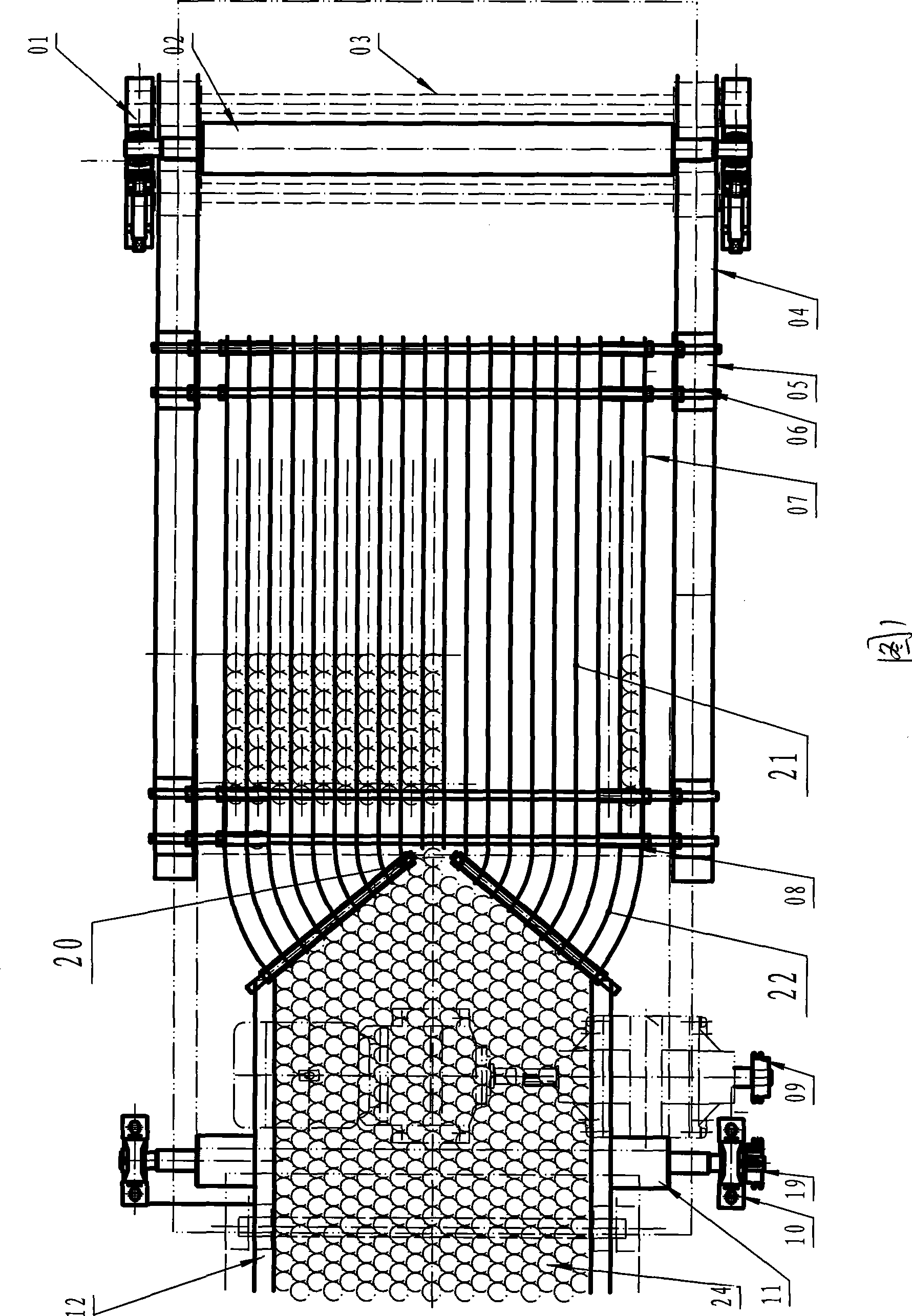

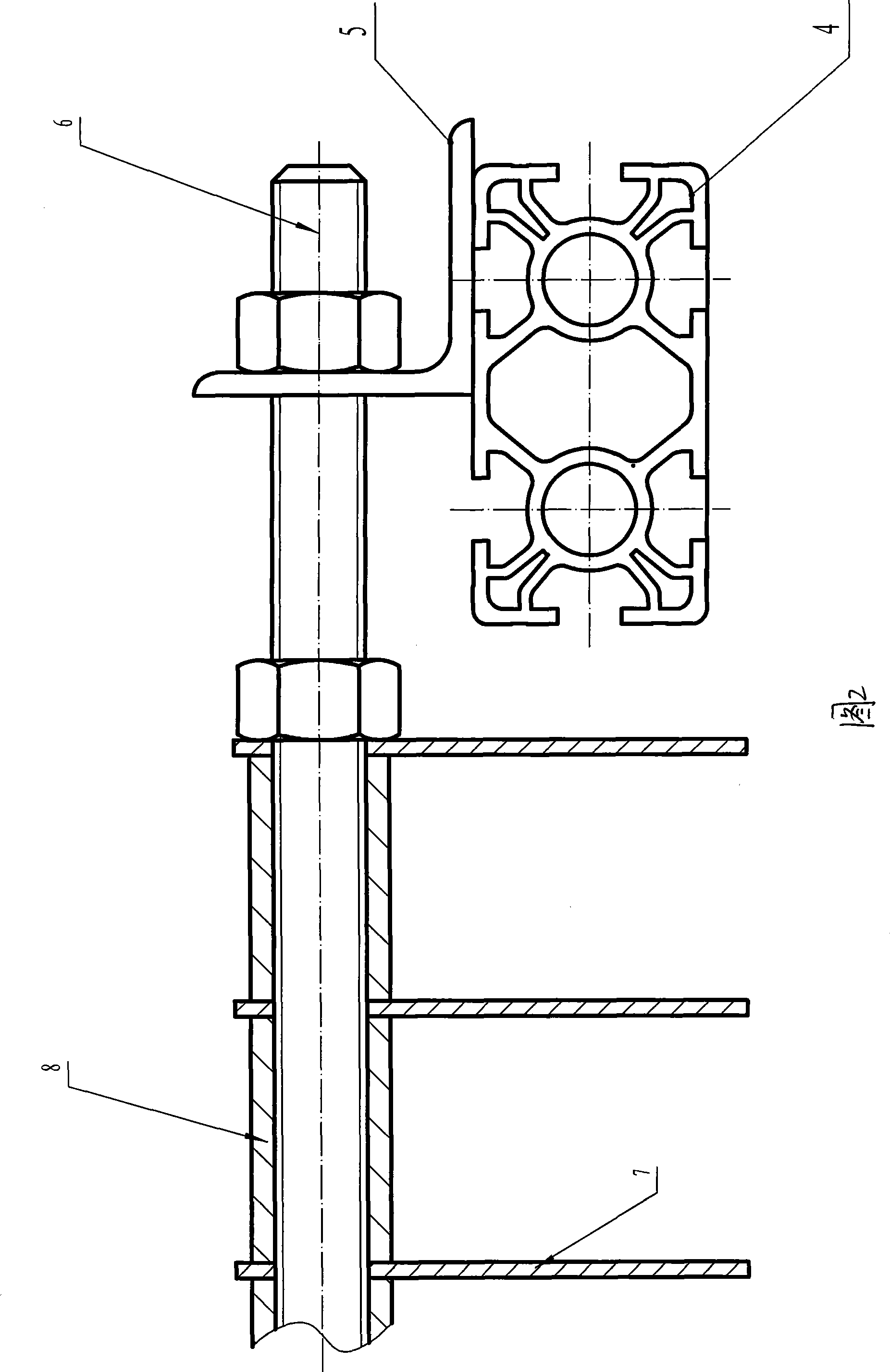

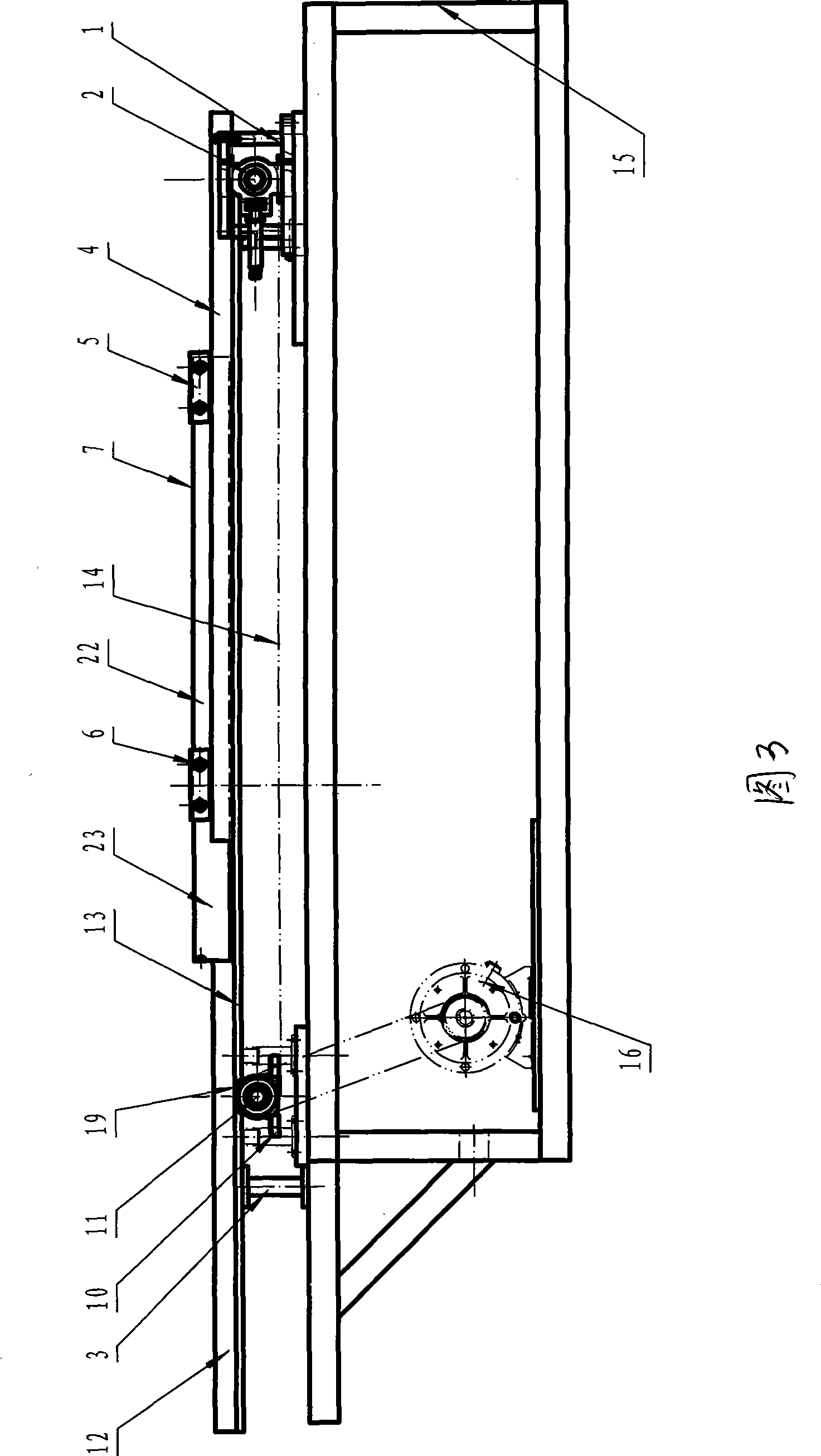

[0014] Below in conjunction with accompanying drawing, the present invention will be further described: a kind of high-efficiency bottle cap arranger, comprises frame 15, is installed on the motor 18 on the frame 15, is equipped with shaft coupling 17 and brake clutch 16 on the motor 18 shaft, brake clutch The other end of 16 is equipped with drive sprocket 9, bearing block 10 and adjustable bearing block 1 are fixedly installed on the frame 15, bearing block 10 is equipped with driving roller 11, adjustable bearing block 1 is equipped with passive roller 2, driving roller 11 The end is equipped with a driven sprocket 19. The function of the adjustable bearing seat 1 is to adjust the distance between the driving roller 11 and the driven roller 2 so as to adjust the tension of the endless conveyor belt 14. The driving sprocket 9 and the driven sprocket 19 are used Chain connection, there is an endless conveyor belt 14 between the driving roller 11 and the passive roller 2, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com