Defrosting method for low temperature dehumidifier

A dehumidifier, low-temperature type technology, applied in refrigerators, damage protection, refrigeration components, etc., can solve the problems of reduced heat transfer efficiency of evaporators, reduced heat transfer effects of evaporators, and easy damage of solenoid valves, etc., to achieve simple structure, Good defrosting effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

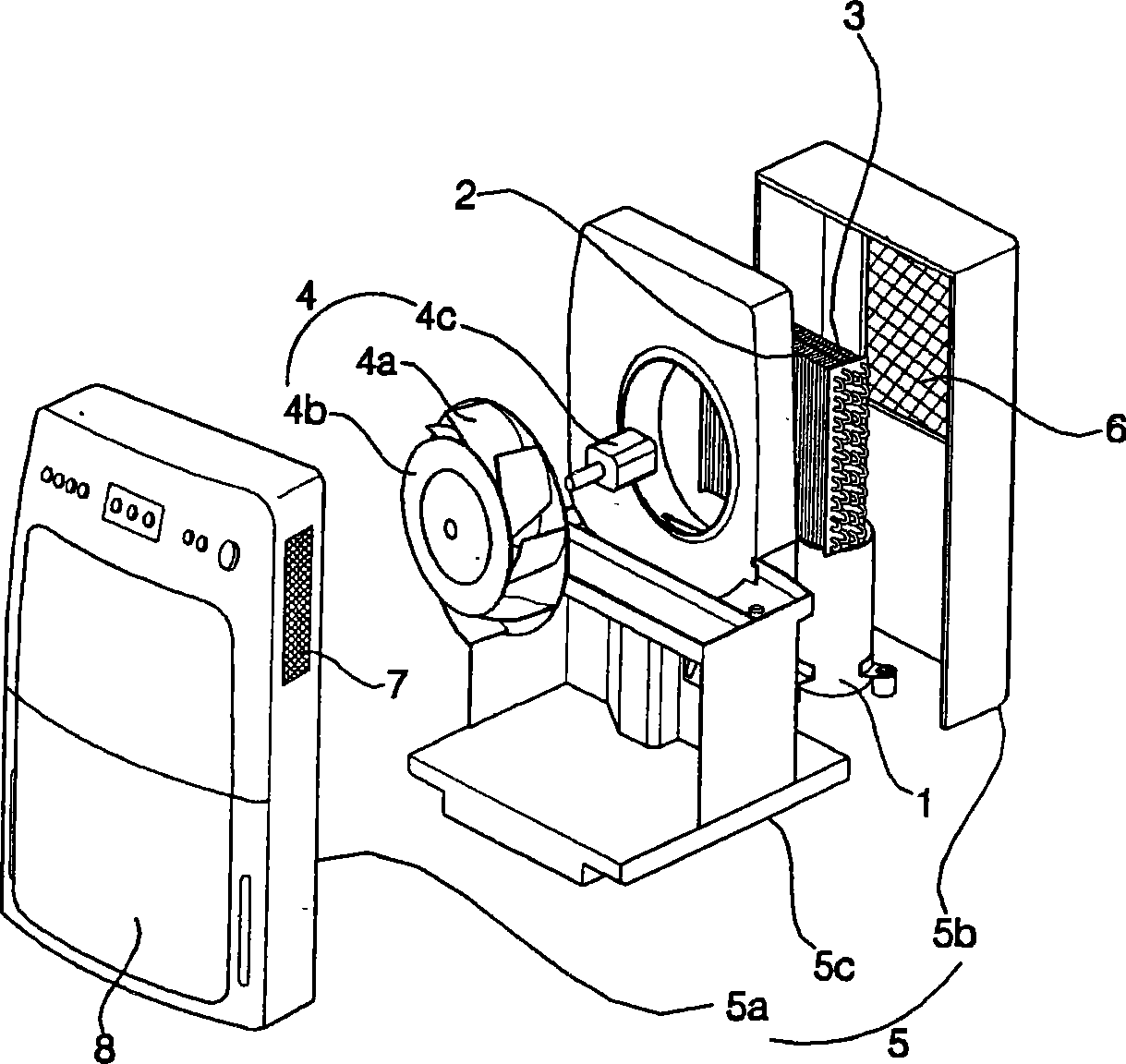

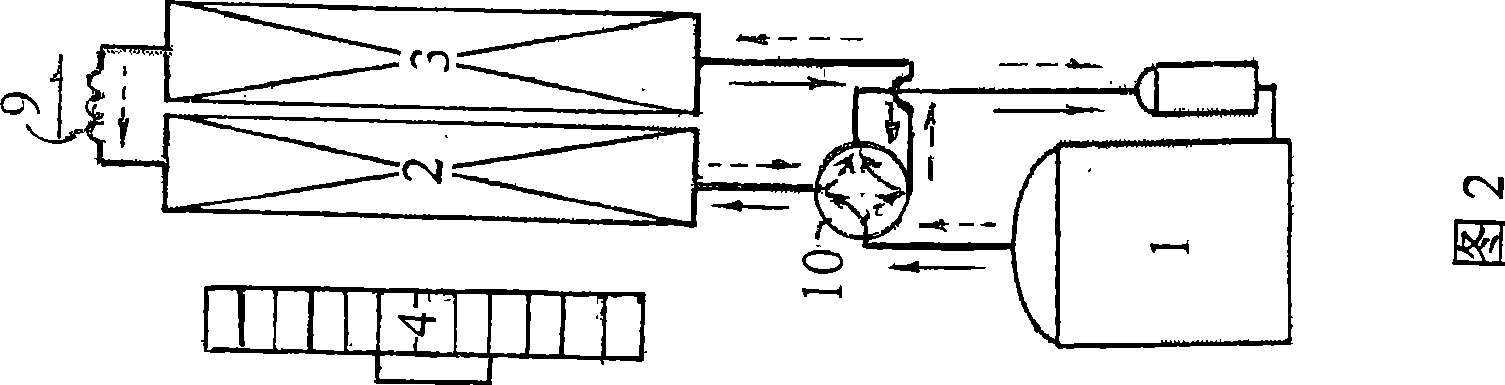

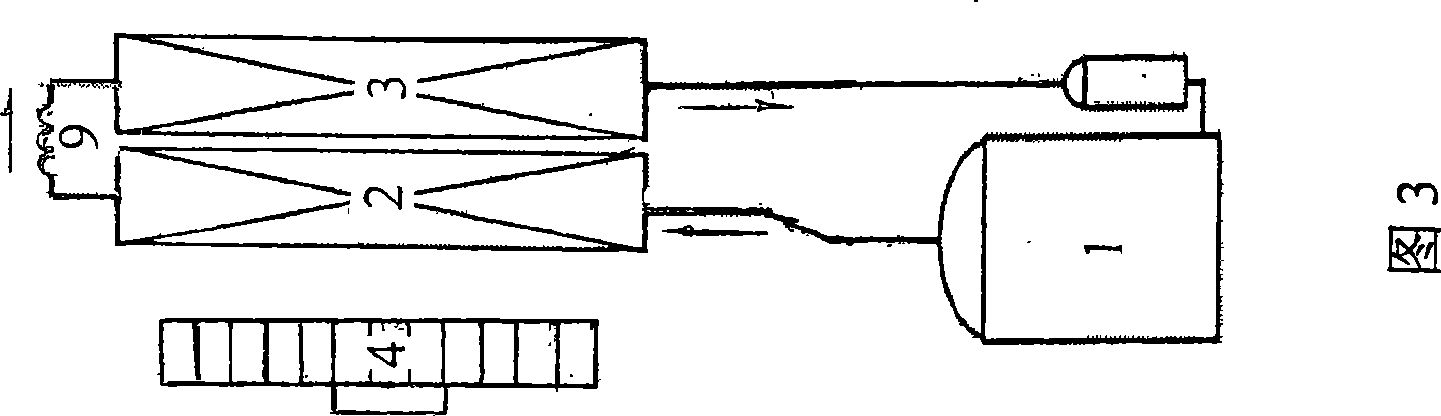

[0029] In order to further illustrate content of the present invention, technical scheme, give following example again and illustrate as follows in conjunction with accompanying drawing:

[0030] As shown in Figures 3, 5, and 7, the defrosting method of the low-temperature dehumidifier of the present invention is to use the dehumidifier evaporator to send the temperature sensing head temperature signal to the dehumidifier in the refrigerant circulation pipeline of the dehumidifier shown in Figure 3 The middle controller (not shown) is controlled by the controller to open and close the operation of the compressor and adjust the air volume of the fan. It is a low-temperature dehumidifier defrosting method that relies on air flow to defrost the evaporator, such as Figure 5 , 7 In the example shown, it runs for 20 minutes with the compressor turned on and the fan at the set air volume for dehumidification. At the same time, the temperature of the exhaust pipe of the evaporator is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com