Dragging device with high starting performance induction motor and frequency transformer cooperatively running

A technology of induction motor and starting performance, which is applied in the direction of AC motor control, starter parts, electrical components, etc., can solve the high problems of motors and frequency converters, achieve high safety factor operation, ensure optimal efficiency, and have obvious energy-saving effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

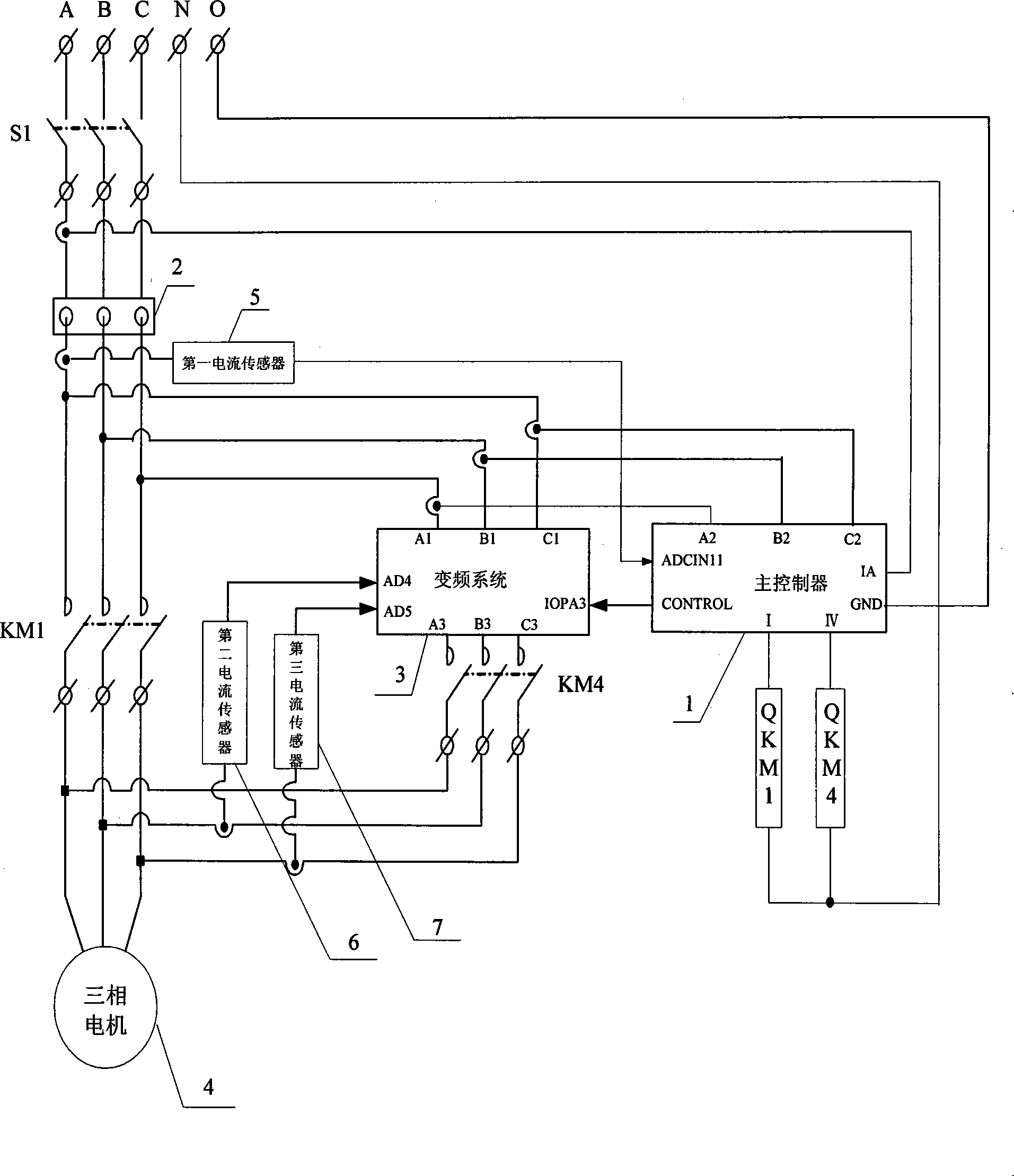

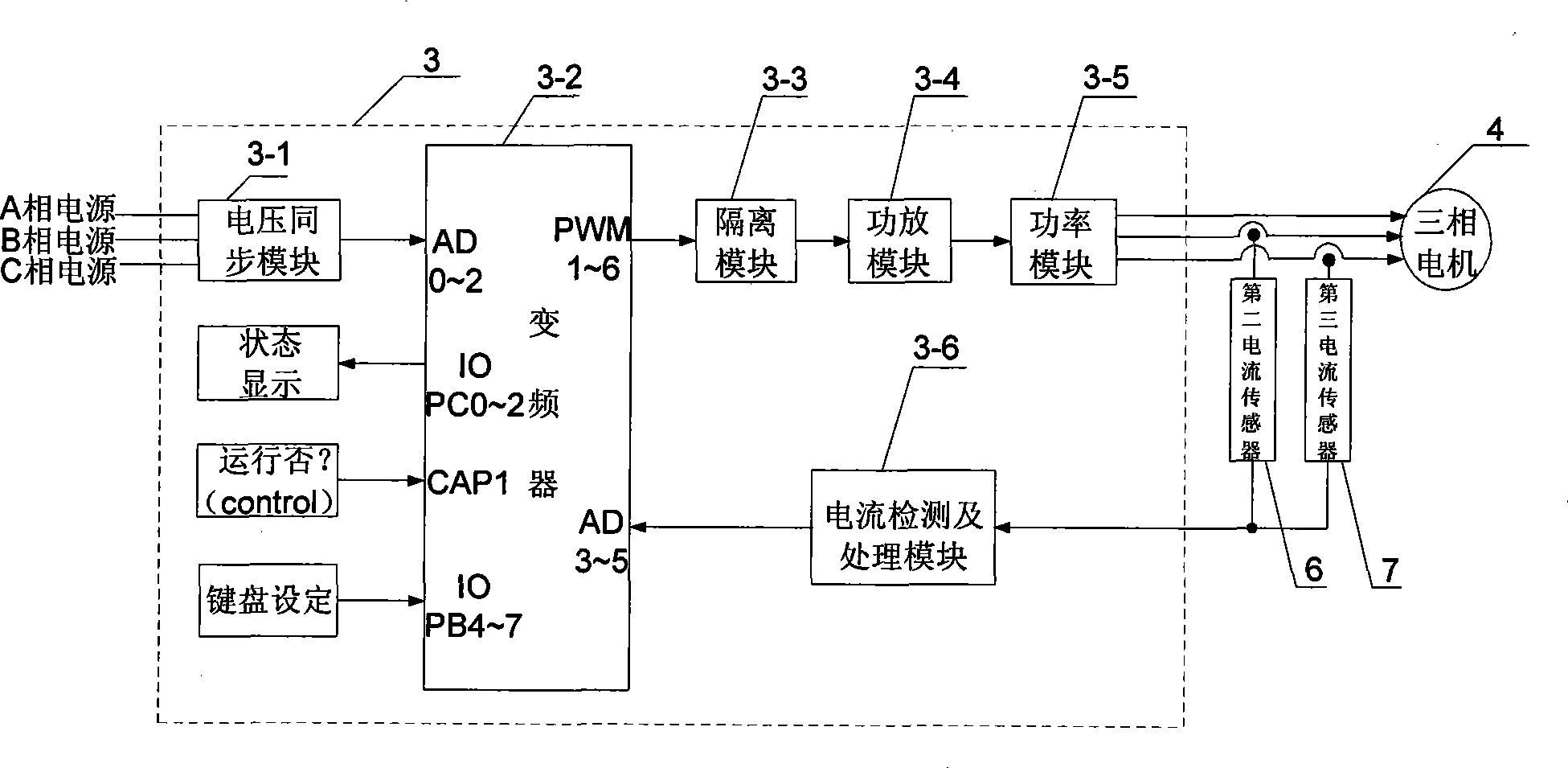

[0010] Specific implementation mode one: refer to figure 1 Describe this specific embodiment, the driving device for the joint operation of the induction motor with high starting performance and the frequency converter, which includes: the first AC contactor KM1, the fourth AC contactor KM4, the frequency conversion system 3, the three-phase motor 4, the first current Sensor 5, the second current sensor 6, the third current sensor 7 and the main controller 1, the A-phase static terminal of the first AC contactor KM1, the B-phase static terminal of the first AC contactor KM1 and the first AC contactor KM1 The C-phase static terminal of the frequency conversion system 3 is respectively connected to the A-phase power input terminal A1, the B-phase power input terminal B1 and the C-phase power input terminal C1 of the frequency conversion system 3, and the A-phase power output terminal A3 and the B-phase power output terminal of the frequency conversion system 3 The terminal B3 an...

specific Embodiment approach 2

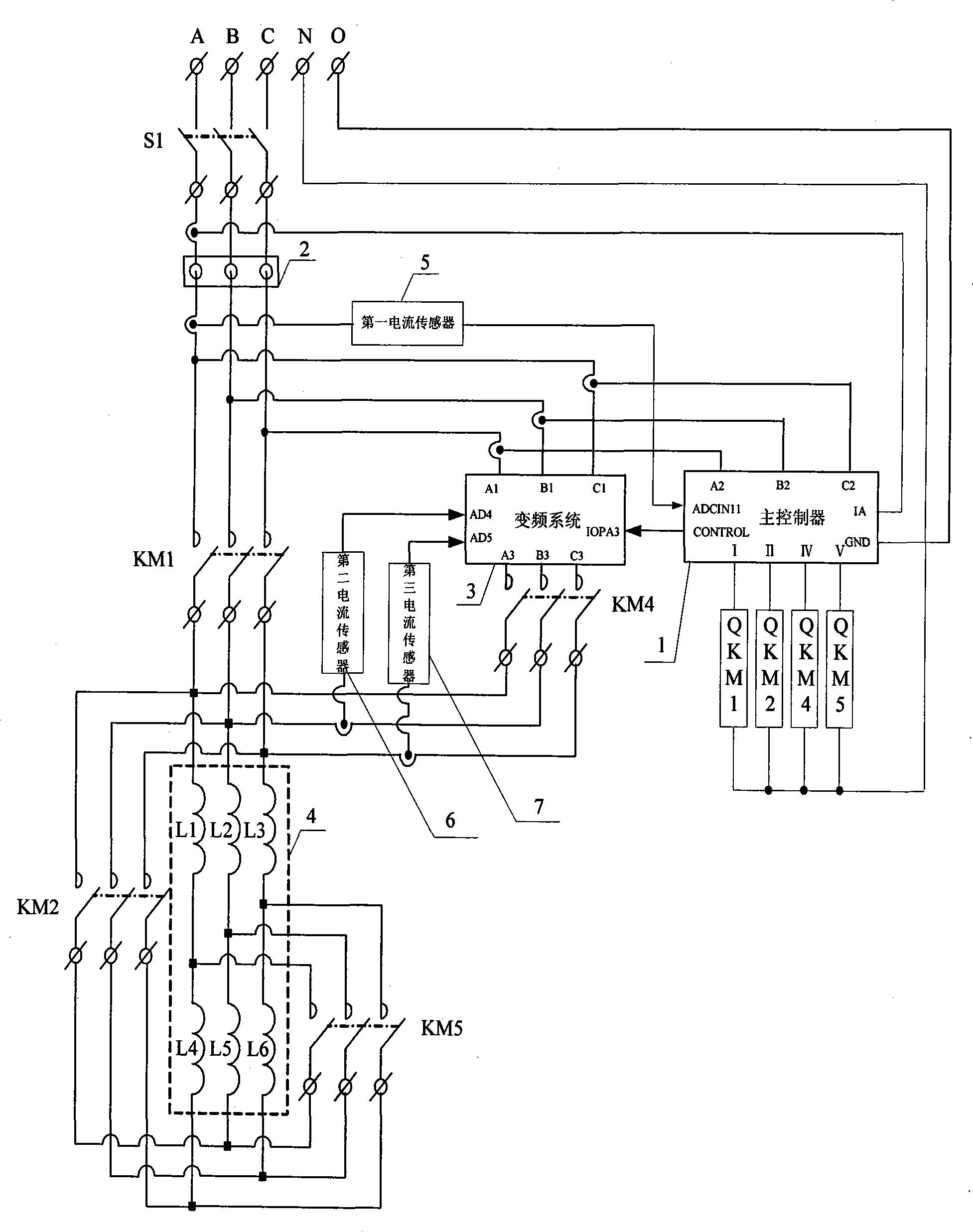

[0013] Specific implementation mode two: refer to figure 2 Describe this specific embodiment, the difference between this embodiment and specific embodiment 1 is that it also includes the second AC contactor KM2 and the fifth AC contactor KM5, and the windings of its three-phase motor 4 include: motor winding L1, motor winding L2, motor winding L3, motor winding L4, motor winding L5 and motor winding L6, the ends of the motor winding L1, motor winding L2 and motor winding L3 are respectively connected to the head ends of the motor winding L4, motor winding L5 and motor winding L6 , the A-phase static end of the second AC contactor KM2, the B-phase static end of the second AC contactor KM2, and the C-phase static end of the second AC contactor KM2 are respectively connected to the first end of the motor winding L1 and the motor winding L2 The first end of the first AC contactor KM2 is connected to the first end of the motor winding L3, and the A-phase moving end of the second ...

specific Embodiment approach 3

[0015]Specific embodiment three: the difference between this embodiment and specific embodiment two is that it also includes: a motor integrated protector 2 and an air circuit breaker S1, and the three-phase power supply is connected to the A-phase static end and the air circuit breaker of the air circuit breaker S1 respectively. The B-phase static end of the switch S1 is connected to the C-phase static end of the air-break switch S1, the A-phase moving end of the air-breaking switch S1, the B-phase moving end of the air-breaking switch S1, and the C-phase moving end of the air-breaking switch S1 Respectively connected to the A-phase current input end of the integrated motor protector 2, the B-phase current input end of the integrated motor protector 2 and the C-phase current input end of the integrated motor protector 2, the A-phase current input end of the integrated motor protector 2 The output terminal, the B-phase current output terminal and the C-phase current output term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com