Method and device for producing winding liner with spacer for unvulcanized strip rubber member, and method and device for producing spacer member for winding

A technology for manufacturing devices and separators, which is applied in the directions of corrugated products, winding strips, sending objects, etc., and can solve the problems of no proposed manufacturing method and device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Hereinafter, embodiments of the present invention will be described based on the drawings. In addition, in the following description, the same code|symbol is attached|subjected to the same component as a conventional example, and description is abbreviate|omitted.

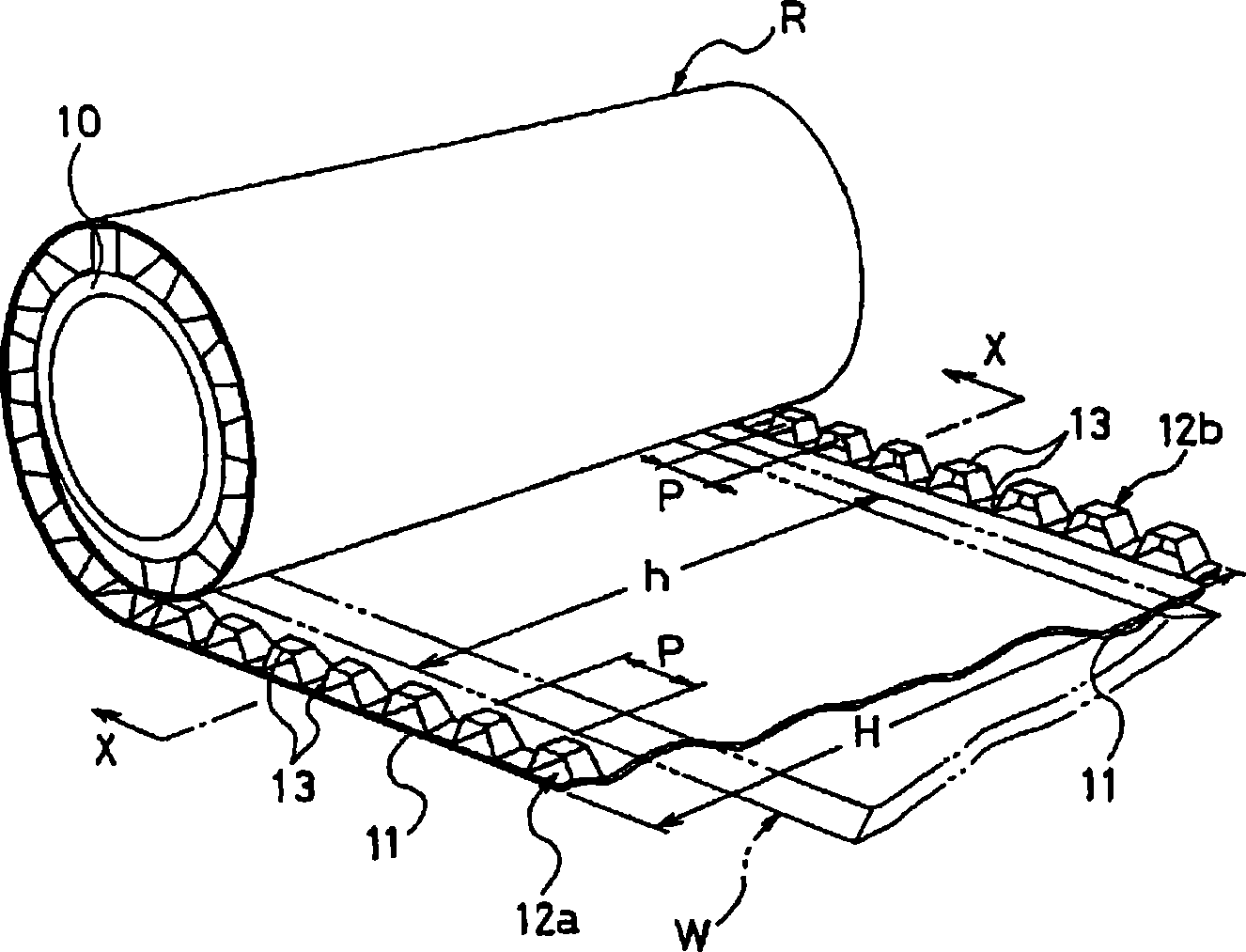

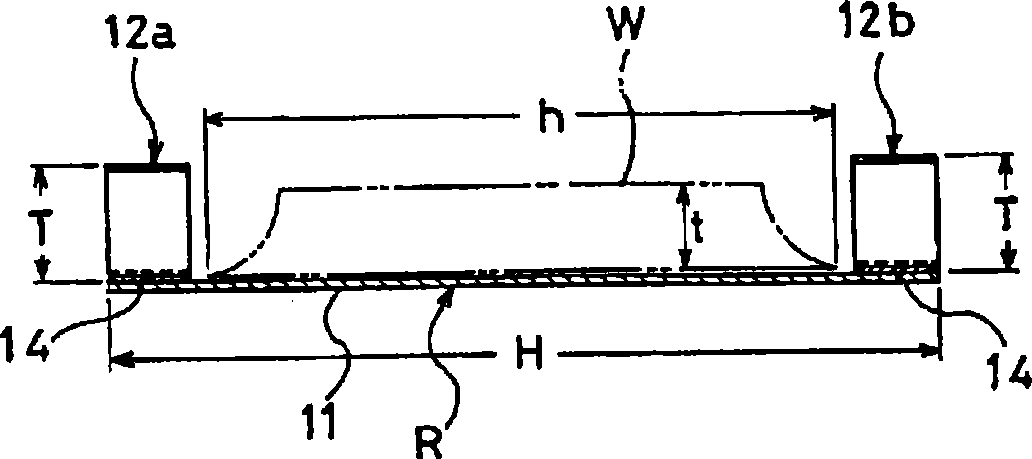

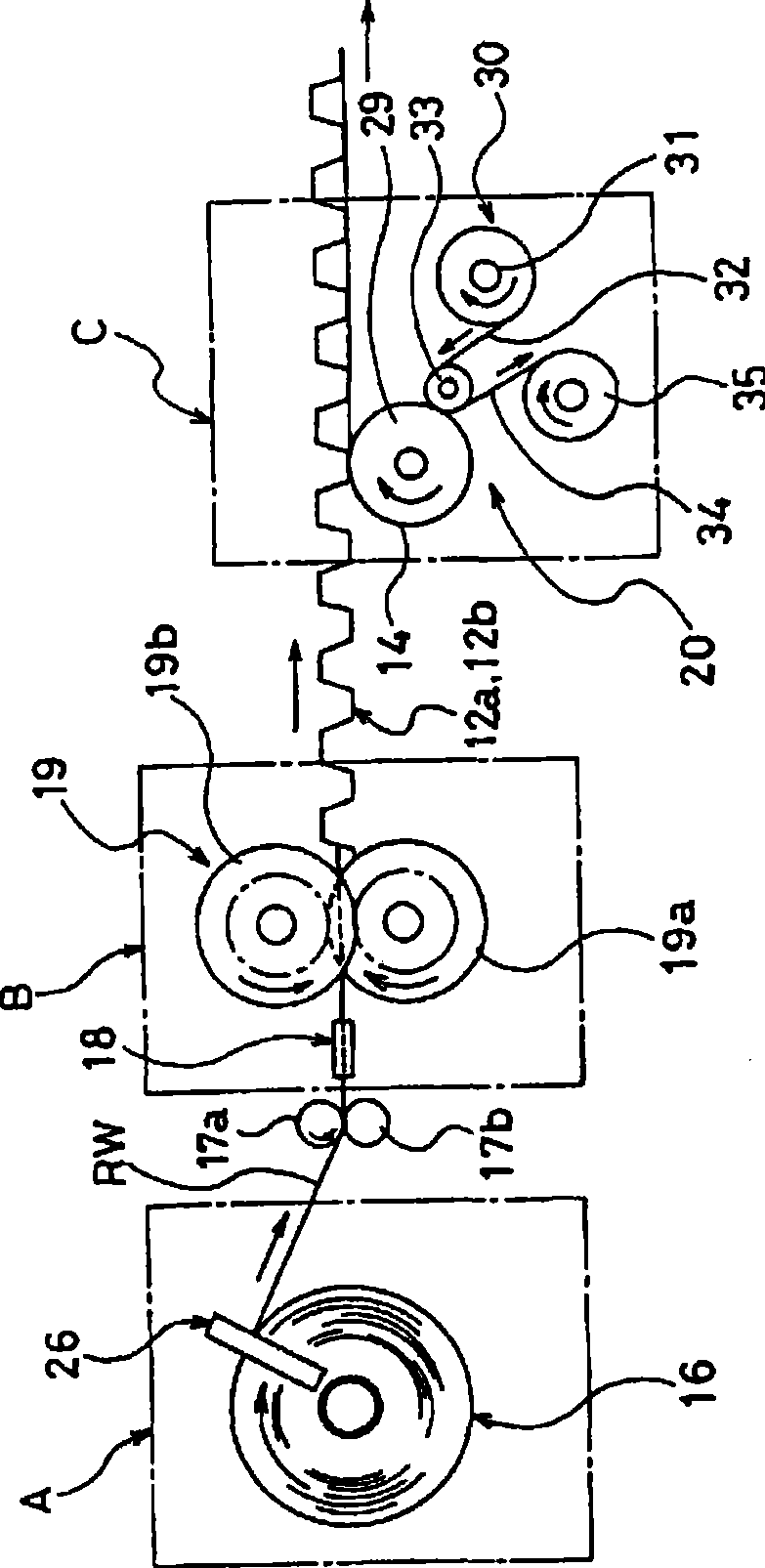

[0077] figure 1 It is a perspective view showing the state in which the unvulcanized strip-shaped rubber member W is wound up on the core material 10 by the winding liner R when the present invention is carried out. The winding liner R of the present invention includes an aluminum alloy (JIS A3000 system, A5000 series, A6000 series alloy, etc.) formed of a strip-shaped base member 11 made of plate materials, and strip-shaped partitions formed in a concave-convex shape mounted on the width direction both sides of the surface of the base member 11 Members 12a, 12b.

[0078] Specifically, the strip-shaped base member 11 is formed by performing an aluminum surface passivation treatment on the surface of an al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com