Wet type dust suction device and filter purification method

A vacuum cleaner and wet-type technology, applied in the field of wet-type vacuum cleaner manufacturing, can solve problems such as inability to vacuum, purify, filter, poor purification effect, and large wind resistance, and achieve good filtration and purification effects, good matching, and wind resistance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

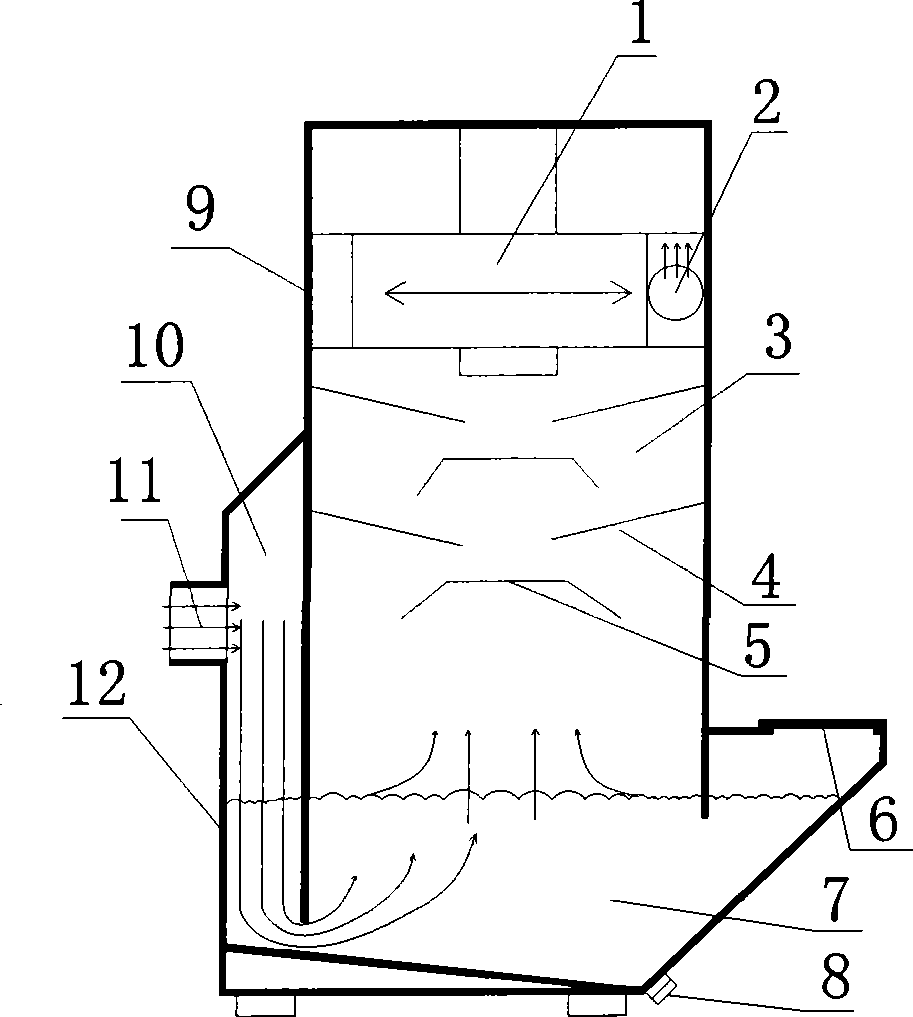

[0012] Embodiment 1: with reference to attached figure 1 . For the wet vacuum cleaner, the centrifugal fan 1 is purchased or processed and is located at the upper part of the inner body 9 of the machine. The labyrinth water retaining mechanism 3 is composed of two or more sets of labyrinth water retaining assemblies, which are stacked at an upper and lower interval. Each group of labyrinth water retaining assemblies is composed of a water retaining plate 5 and a guide plate 4. The trapezoidal structure is processed and formed by the prior art, and the guide plate 4 is trumpet-shaped and processed by the prior art. The guide plate 4 is located above the water baffle 5 and cooperates with the water baffle 5 at a distance. The distance is generally between 2 and 10 cm and depends on the power of the wet vacuum cleaner. The labyrinth water retaining mechanism 3 is located (installed) in the machine body 9 and below the centrifugal fan 1, and the labyrinth water retaining mechani...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, the labyrinth water retaining mechanism 3 is composed of a group of labyrinth water retaining assemblies.

Embodiment 3

[0014] Embodiment 3: On the basis of Embodiment 1 or 1 and 2, start the centrifugal fan 1, and under the action of the centrifugal fan 1, pass through the negative pressure area of the labyrinth water retaining mechanism 3, the reservoir 7, and the air diffusion chamber 10, The air inlet 11 forms a high-pressure negative pressure zone, and the high-temperature dust (combustion particles) air or high-temperature dust (combustion particles) airflow to be dedusted is sucked into the airflow diffusion chamber 10, and the high-temperature dust airflow enters the airflow diffusion chamber from the air inlet 11 10, because the space of the airflow diffusion chamber 10 is much larger than the space of the air inlet, the high-pressure and high-temperature dust airflow entering the airflow diffusion chamber 10 loses pressure instantly and the flow velocity decreases, and the dust entrained in the high-temperature dust airflow is affected by its own weight. And the effect of the earth's...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com