Elastic heat conducting and radiating device

A technology of elastic heat conduction and heat dissipation device, which is used in semiconductor devices, cooling/ventilation/heating transformation, semiconductor/solid-state device components, etc., to achieve the effect of solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

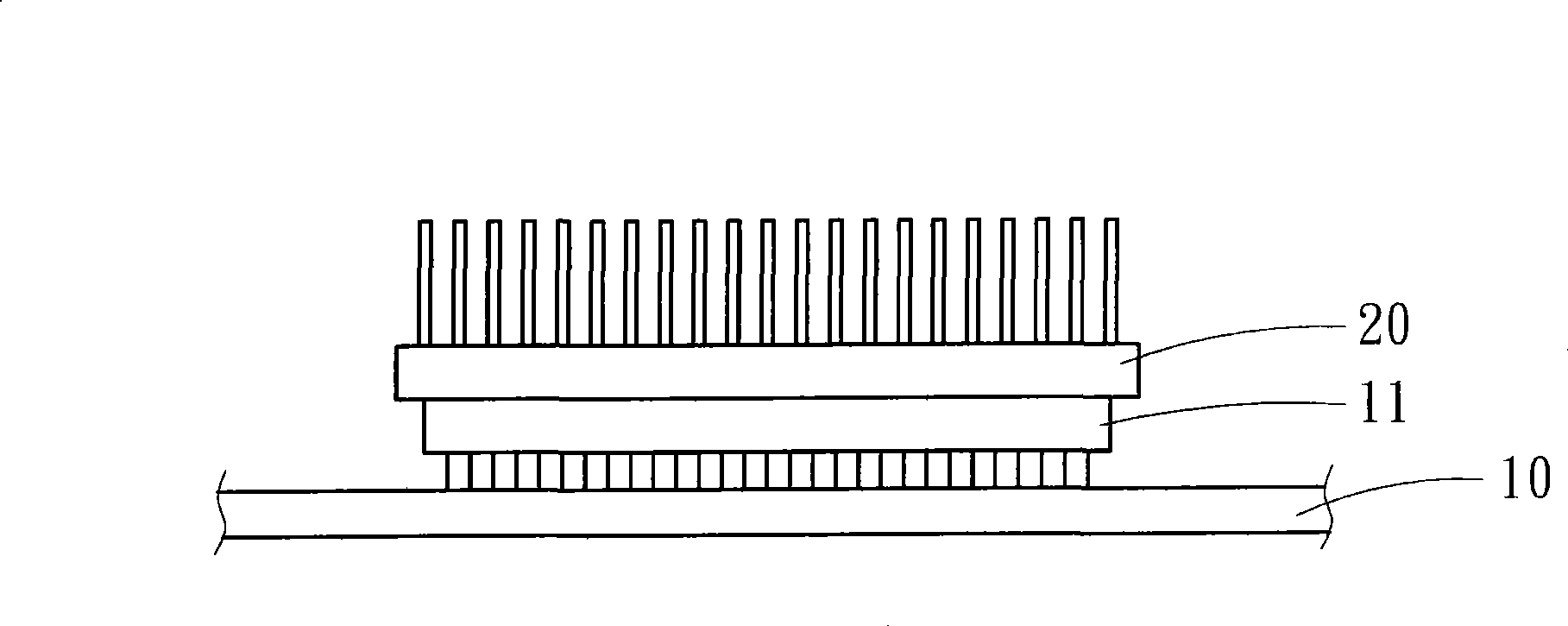

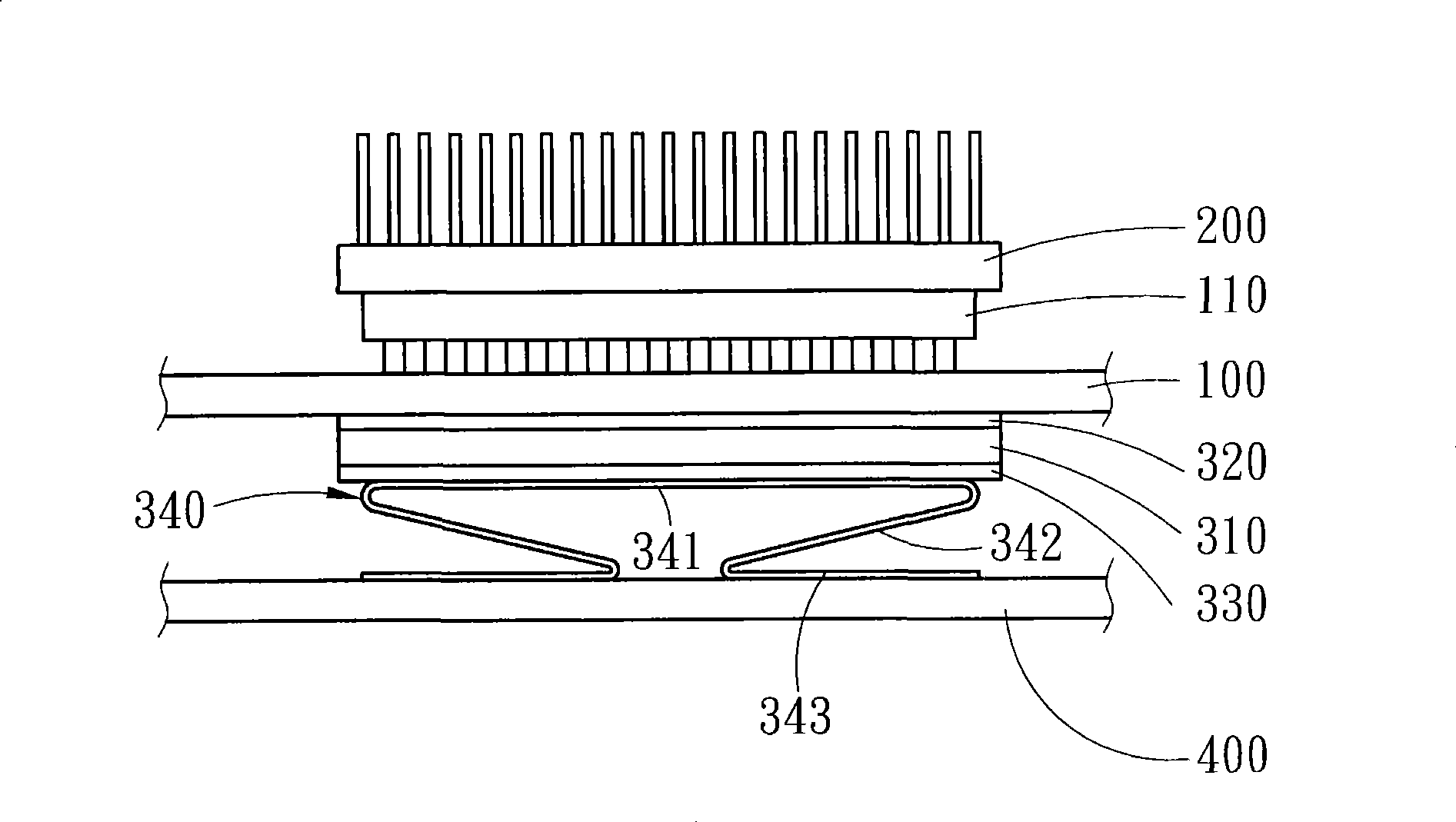

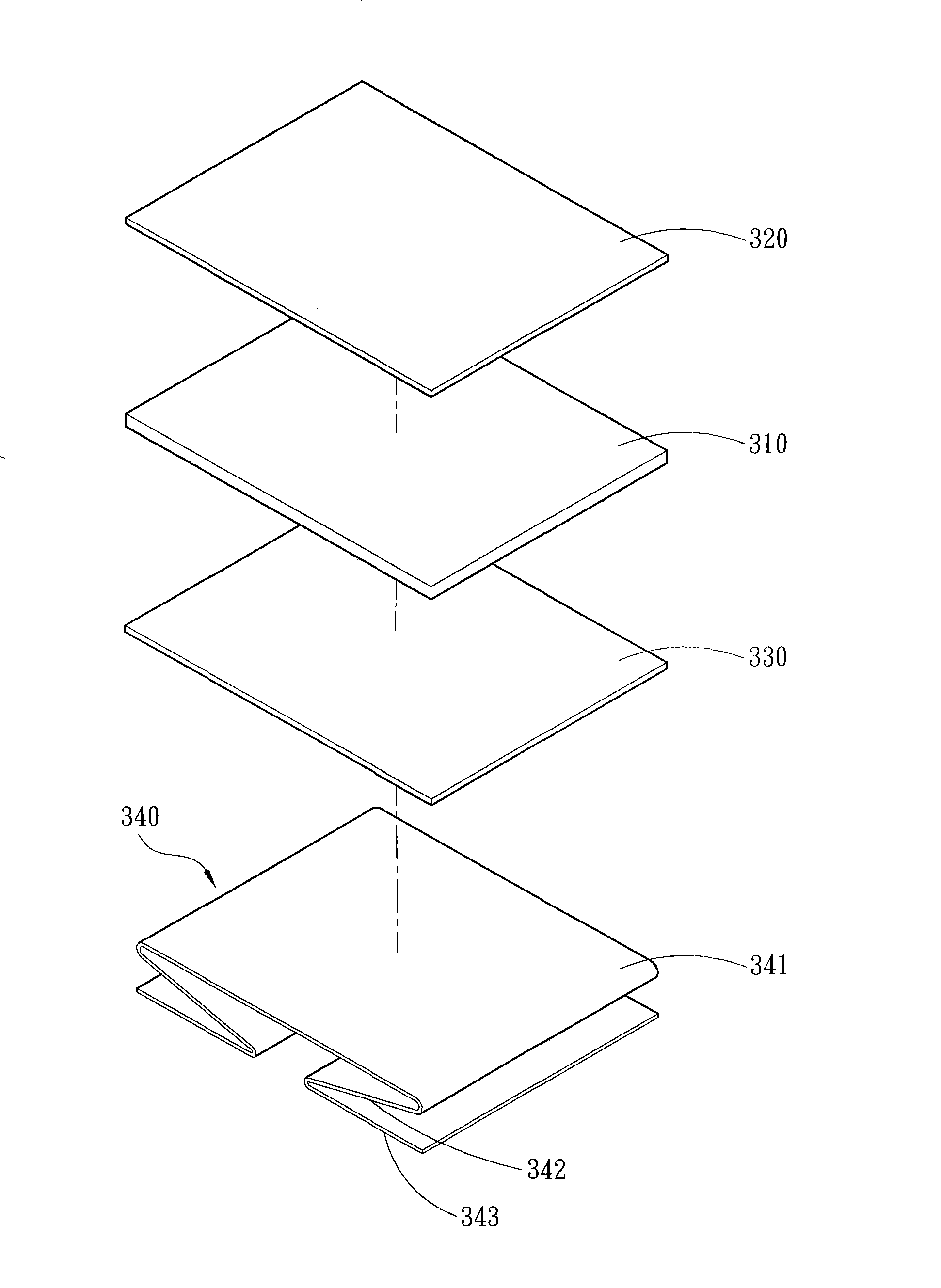

[0038] Please also see figure 2 and image 3 , the present invention is a circuit board 100 ( image 3 For the circuit board 100 and the housing wall 400, only a fragment is drawn for illustration), an elastic heat conduction and heat dissipation device for dissipating heat from an electronic component 110 on the circuit board 100, the present invention includes: a heat sink 310, It is fixed on the bottom of the circuit board 100 by means of a first adhesive layer 320 on the upper surface, which is used to guide the heat generated by the electronic components 110 on the circuit board 100 to the heat sink 310; and an elastic heat conducting seat 340...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com