Adding calcium sand made by adding calcium coal slag by using cyclone boiler, preparation method and use thereof

A technology of calcium sand and cinder, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as security threats to river embankments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is described in further detail.

[0012] A calcium-enriched sand made of calcium-increased coal slag from a cyclone boiler is characterized in that: the nominal particle size of the calcium-enriched sand is 80 μm to 5.00 mm, and the fineness modulus is gradation of 0.7 to 3.7.

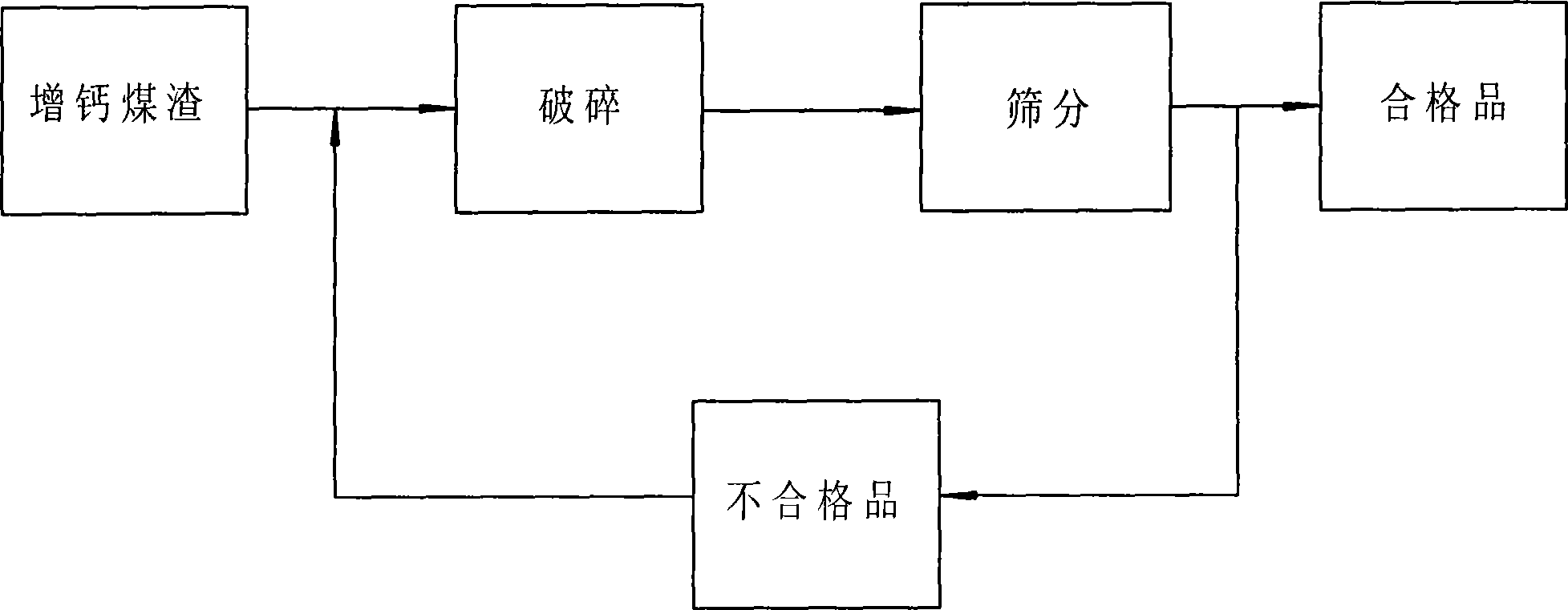

[0013] The second technical solution to realize the object of the present invention is: crush the imported calcium-increasing cinder with a crusher, and then sieve the crushed calcium-increasing cinder with a screening device with a nominal diameter of sieve hole of 80 μm to 5.00 mm, In order to obtain calcium-enriched sand with a nominal particle size of 80 μm to 5.00 mm. Unqualified products after screening can be returned for re-crushing.

[0014] Moreover, the crusher is a ball mill or a straight-through impact crusher.

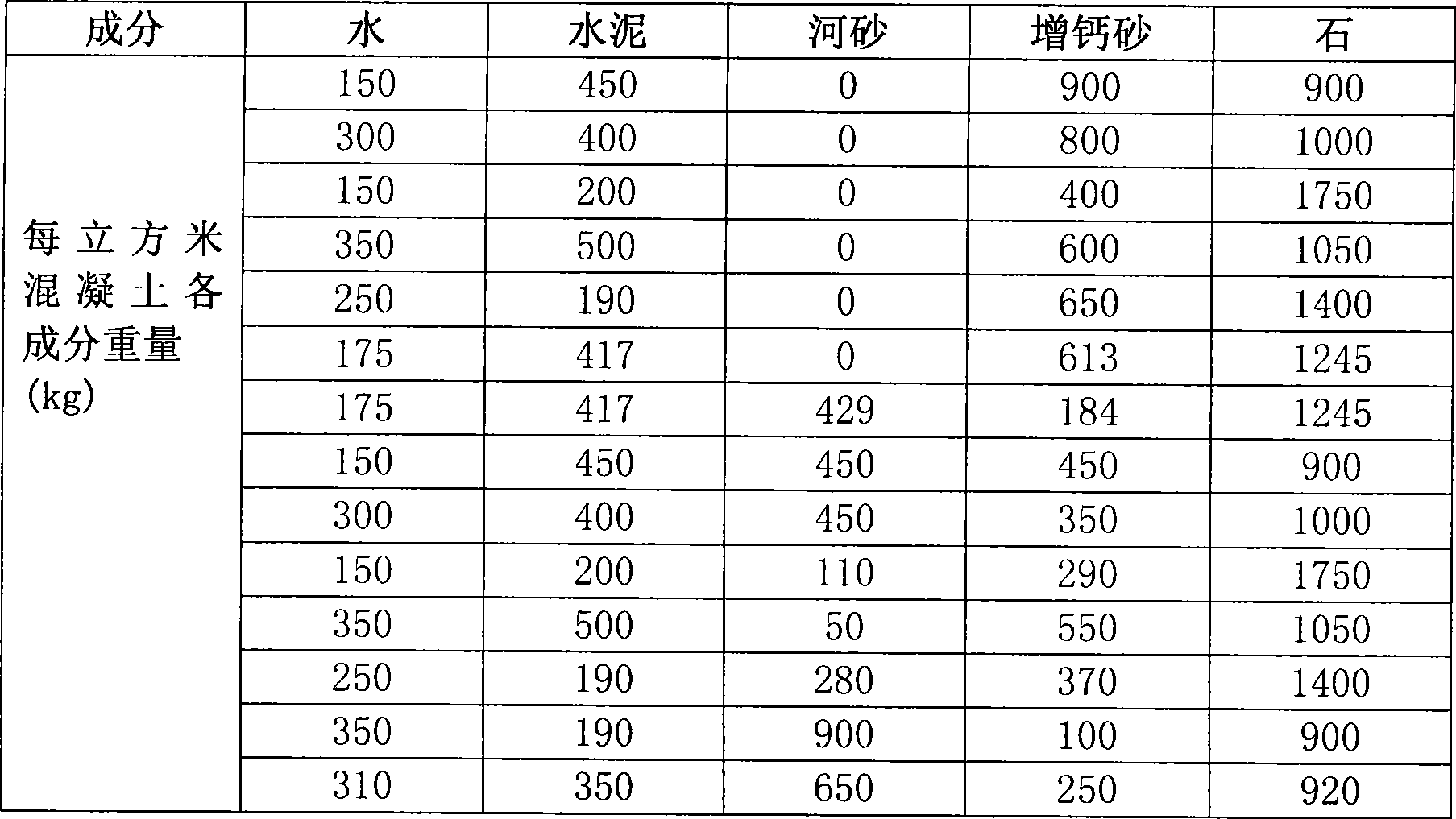

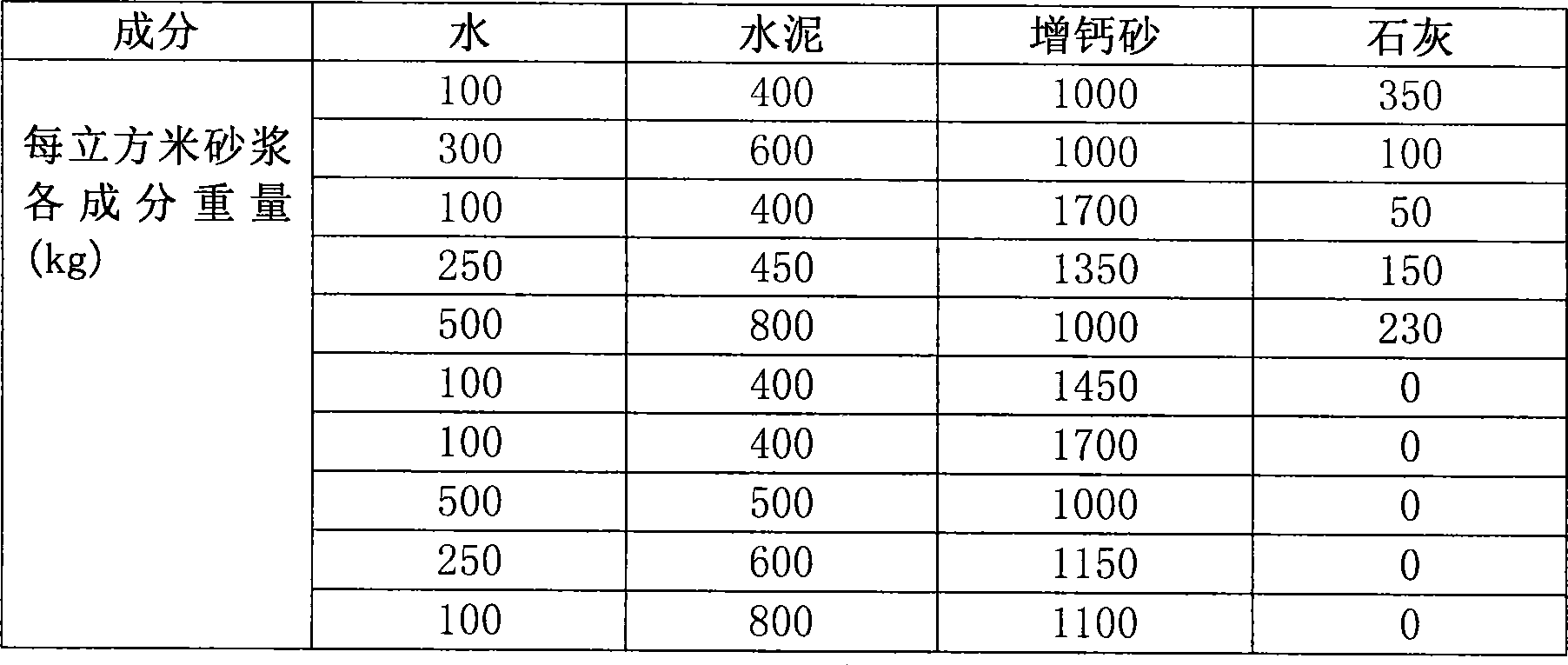

[0015] The 3rd technical scheme that realizes the object of the present invention is: prepare concrete with it,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com