Combination floor and assembling method

A floor and side board technology, applied in the direction of floors, buildings, building structures, etc., can solve problems such as looseness, displacement, and difficult to connect properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

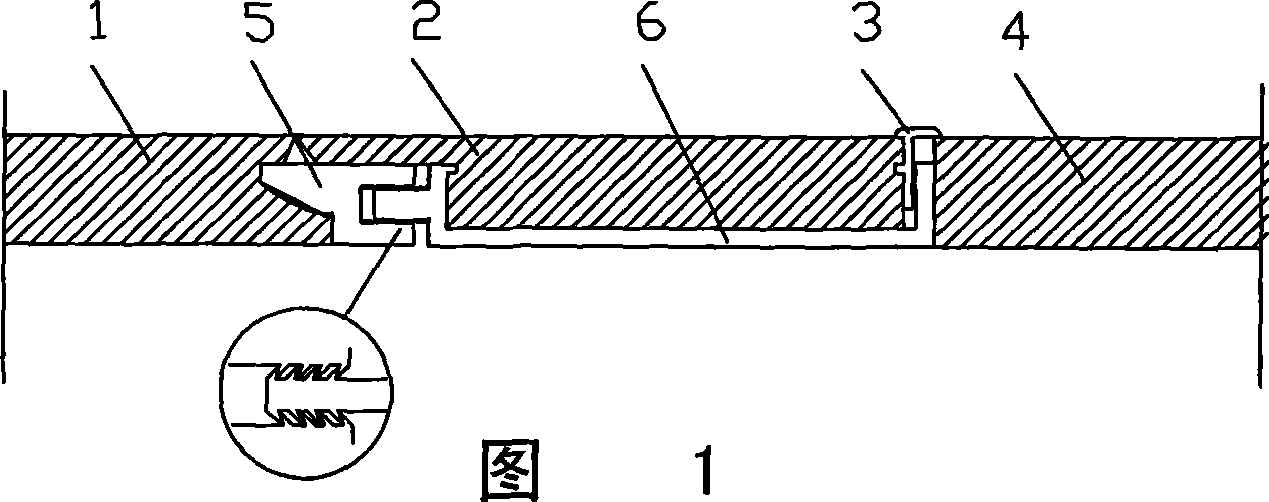

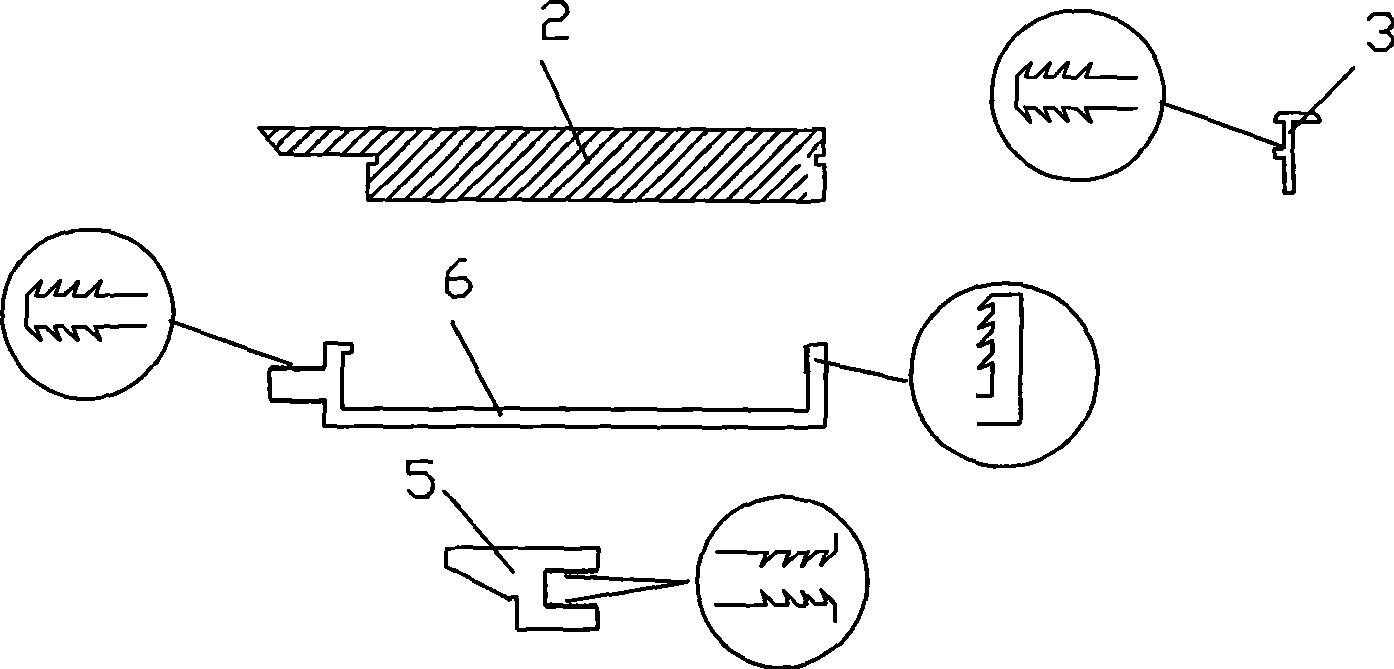

[0019] The assembled combined floor of the present embodiment is as shown in Fig. 1 and figure 2 As shown, the periphery of the parquet floor 1 is shaped on a mortise and tenon concave edge. One side in the width direction of the side panel 2 grooves located around the parquet floor extends from the upper surface to the lap eaves 2-1 flush with the upper surface of the parquet floor, and the bottom falls in the edge groove 6; the lap eaves 2-1 A groove 2-2 is formed at the intersection of the lower surface and the bottom adjacent to the vertical wall of the eaves. Surrounding edge plate 2 is shaped on draw-in groove 2-3 away from the vertical wall middle part of overlapping eaves.

[0020] The main body section of the edge groove 6 placed under the edge plate 2 is " ” shape, a flange 6-1 with a rectangular section extends from one side adjacent to the parquet floor, and barbs are formed on the upper and lower surfaces of the flange 6-1 respectively; There is a hook 6-2 mat...

Embodiment 2

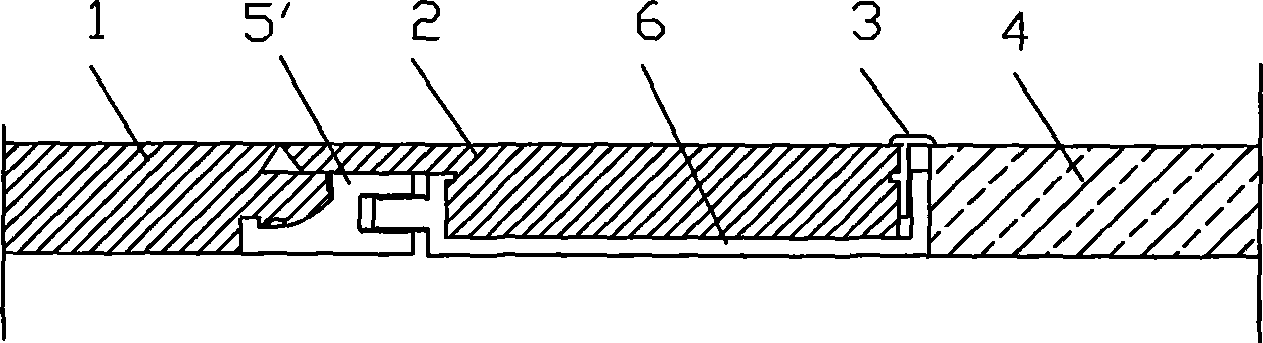

[0030] The assembled combined floor of the present embodiment is as image 3 and Figure 4 As shown, its basic structure is the same as that of Embodiment 1. The difference is that the periphery of the parquet floor 1 is formed with a mortise and insert flange. Therefore, the side of the transition strip 5' adjacent to the parquet floor 1 extends a transition concave clip 5'-1 that matches the parquet floor mortise flange. Its effect and assembling method are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com