A kind of soft package electric core module and manufacturing method thereof

The invention relates to a technology of a battery cell module and a manufacturing method, which are applied in the field of soft-packed battery cell modules and their production, and can solve problems such as battery cell damage, and achieve the effects of improving production efficiency, improving structural strength, and improving qualification rate and yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

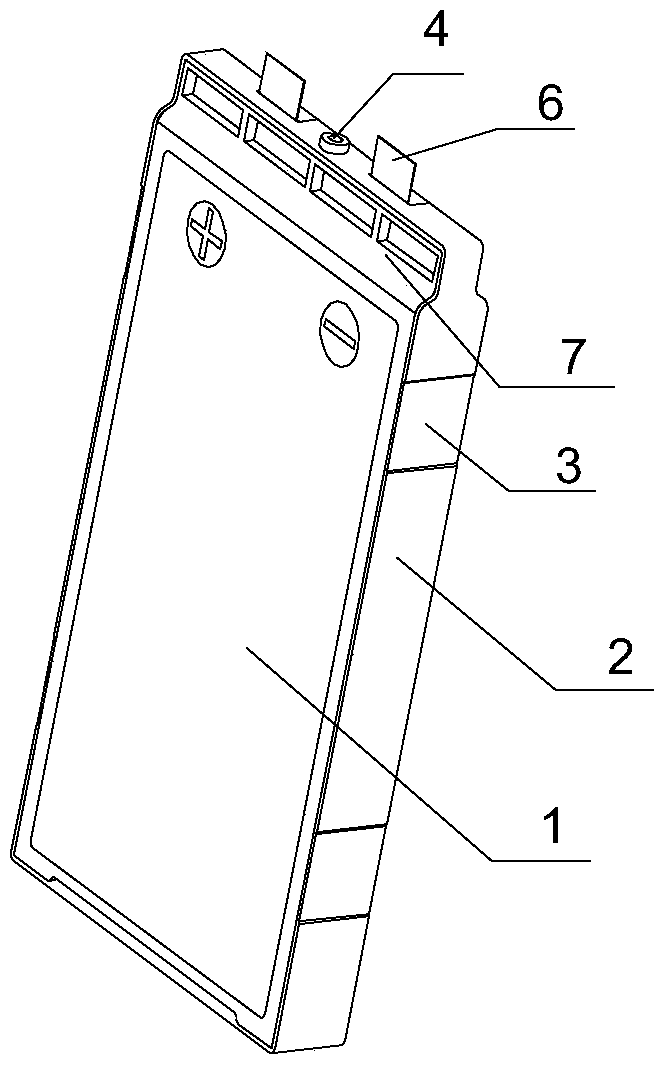

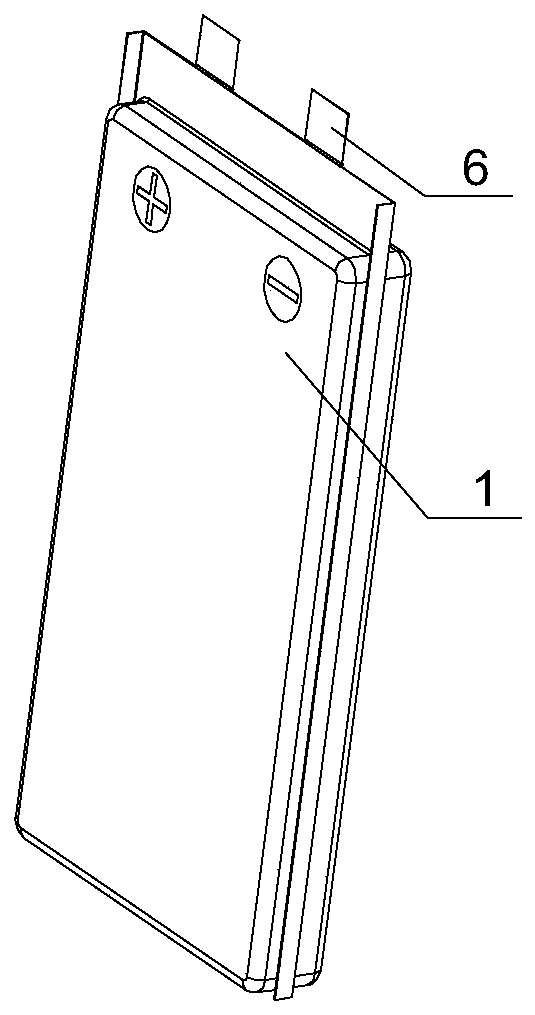

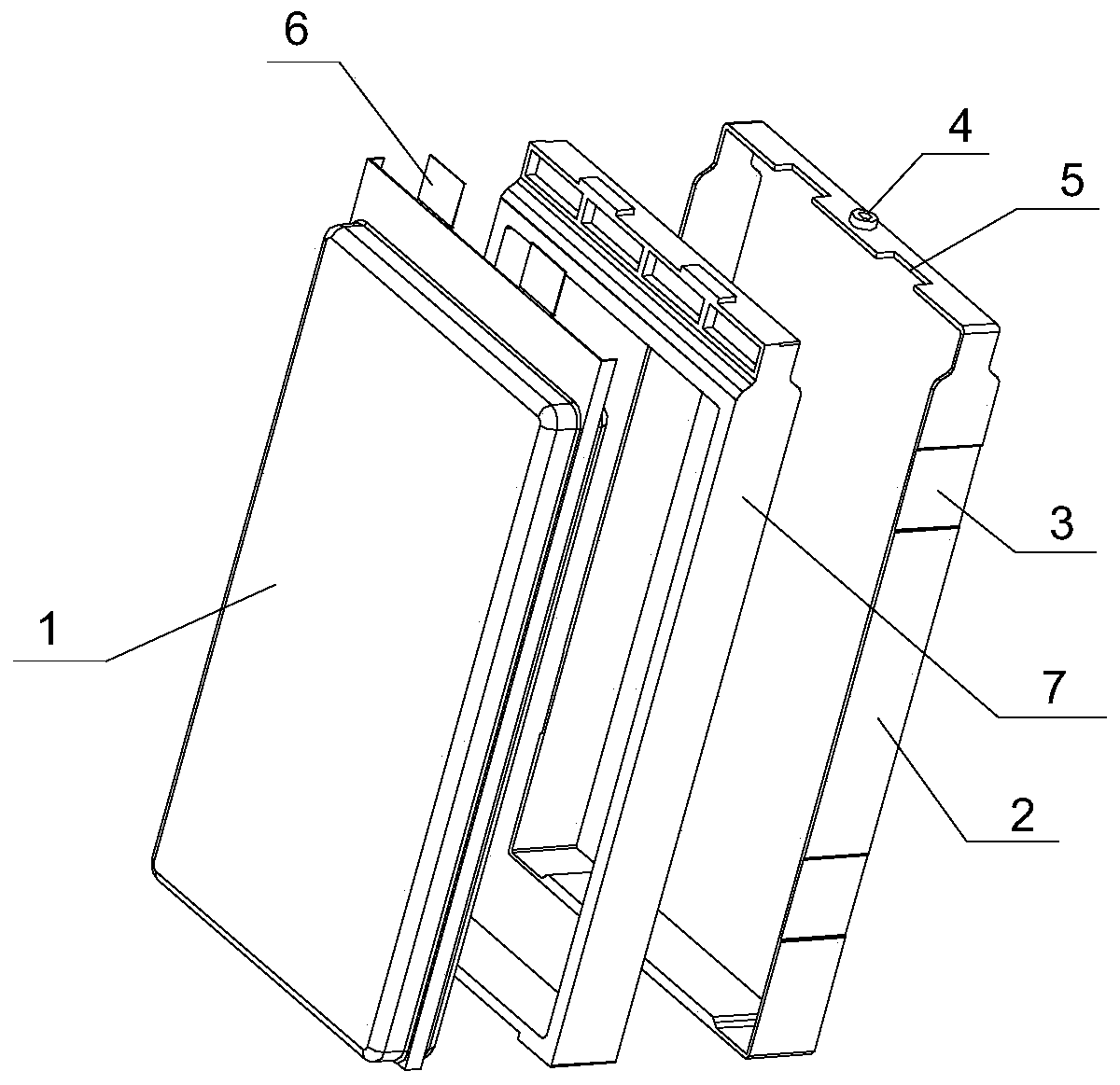

[0029] Such as figure 1 , figure 2 , image 3 As shown, a soft-packed battery module includes a soft-packed battery 1 and a battery frame 2. The battery frame 2 is rectangular, and the battery frame 2 is set around the soft-packed battery 1. The battery frame 2 Cured fixing glue 7 is filled between the inner wall of the inner wall and the soft-packed battery cell 1, and the fixed glue 7 combines the cell frame 2 and the soft-packed battery cell 1 into one. The material of the fixing glue 7 is polyamide. The battery frame 2 is made of ABS plastic. The end of the cell frame 2 is provided with a pair of cell tab slots 5. The position of the cell tab slots 5 corresponds to the position and size of the cell tab 6 on the soft pack cell 1. The cell tab 6 Fastened in the cell lug slot 5. There are binding card slots 3 on both sides of the cell frame 2. The binding card slots 3 are inserted into the outer surfaces of the cell frame 2. The direction of the binding card slot 3 is t...

Embodiment 2

[0038] In step B, the injection temperature is 135°C, and the injection pressure is 1.8kgf / cm2. In step C, the mold is closed for 18 seconds, the mold temperature is controlled at 50°C, and the cycle from mold closing to mold opening is 28 seconds each time. All the other are with embodiment 1.

Embodiment 3

[0040] In step B, the injection temperature is 150°C, and the injection pressure is 1.5kgf / square centimeter. In step C, the mold is closed for 20 seconds, the mold temperature is controlled at 55°C, and the cycle from mold closing to mold opening is 30 seconds each time. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com