Portable assembled fan

A fan and fan blade technology is applied in the field of fans that are assembled and easy to carry. It can solve the problems of inconvenient disassembly, difficult cleaning and maintenance, and large volume, and achieve the effects of easy cleaning, reducing difficulty and ensuring cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

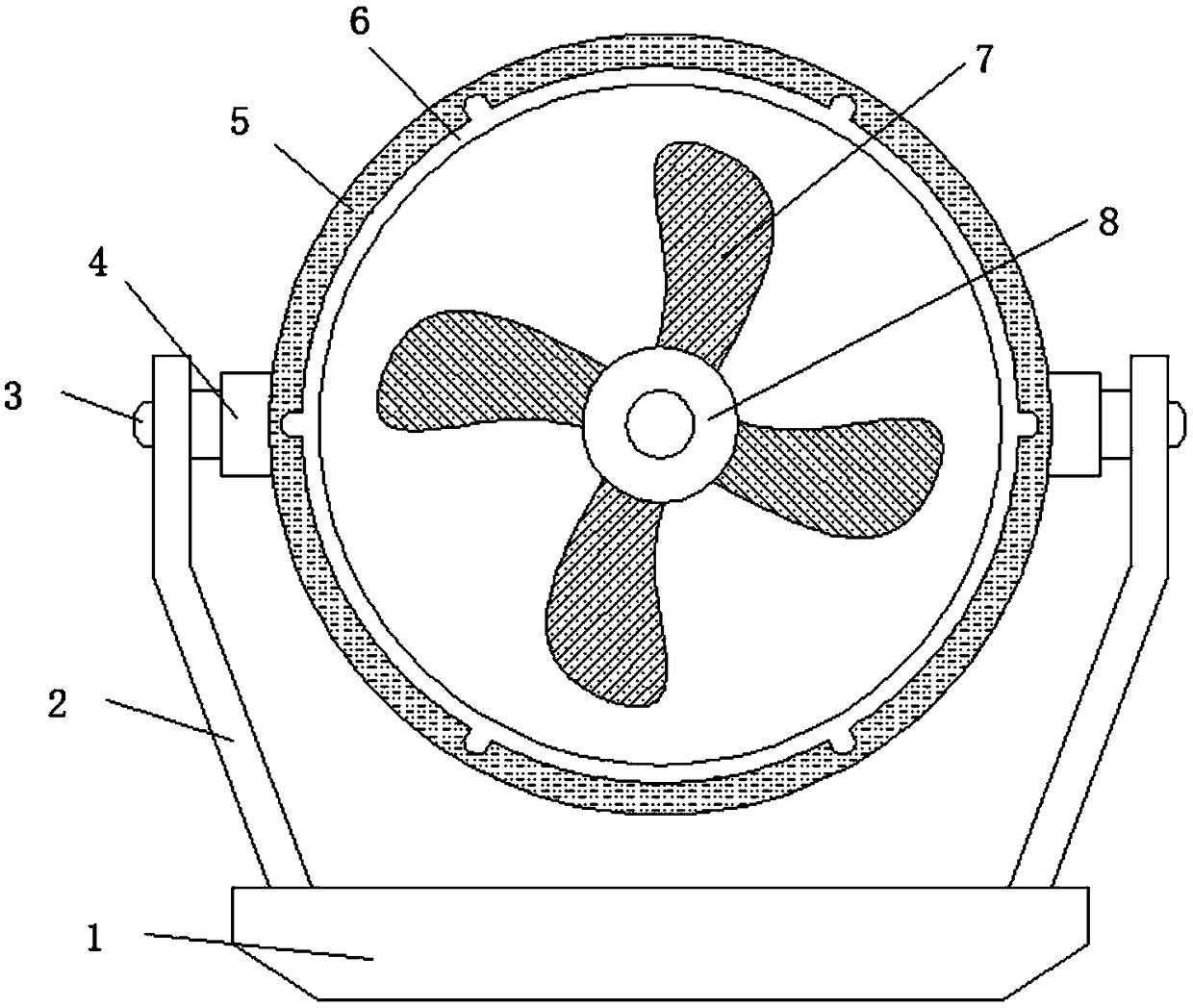

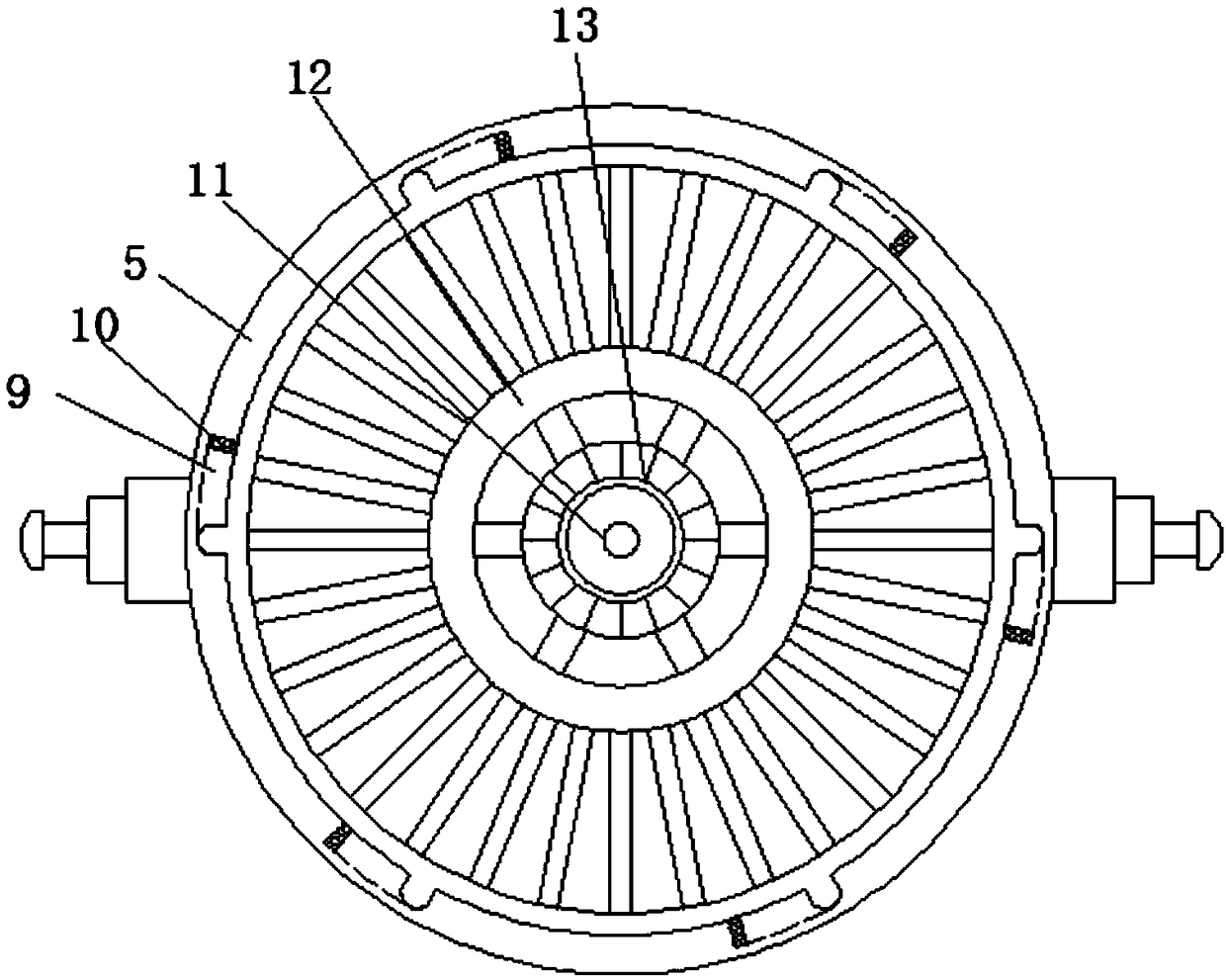

[0027] Embodiment one, with reference to Figure 1-4 , a combined assembled and portable fan, including a bracket bottom plate 1, two side risers 2 are symmetrically welded on the upper surface of the bracket bottom plate 1, and a fan back cover is connected between the two side risers 2 through a rotating pin 4 5. A motor fixing frame 12 is welded at the center of the front surface of the fan rear cover 5, and a driving motor 13 is welded at the center of the motor fixing frame 12. One end of the driving motor 13 is welded with a rotating shaft 11, and one end of the rotating shaft 11 is clamped with a fan blade. Mounting plate 8, fan blade 7 is welded on the outer wall of fan blade mounting plate 8, fan front cover 6 is clamped at the edge of the front surface of fan rear cover 5 through card slot 9, and the outer wall of fan front cover 6 is welded with a connection for use with card slot 9 There are four clamping plates 20 and four fixing pins 16 , and the four fixing pins...

Embodiment 2

[0028] Embodiment two, refer to figure 1 and figure 2 , Fix between the two side vertical plates 2 and the rotating pin shaft 4 by the fixing bolt 3, the side vertical plate 2 can be separated from the rotating pin shaft 4 by dismounting the fixing bolt 3.

Embodiment 3

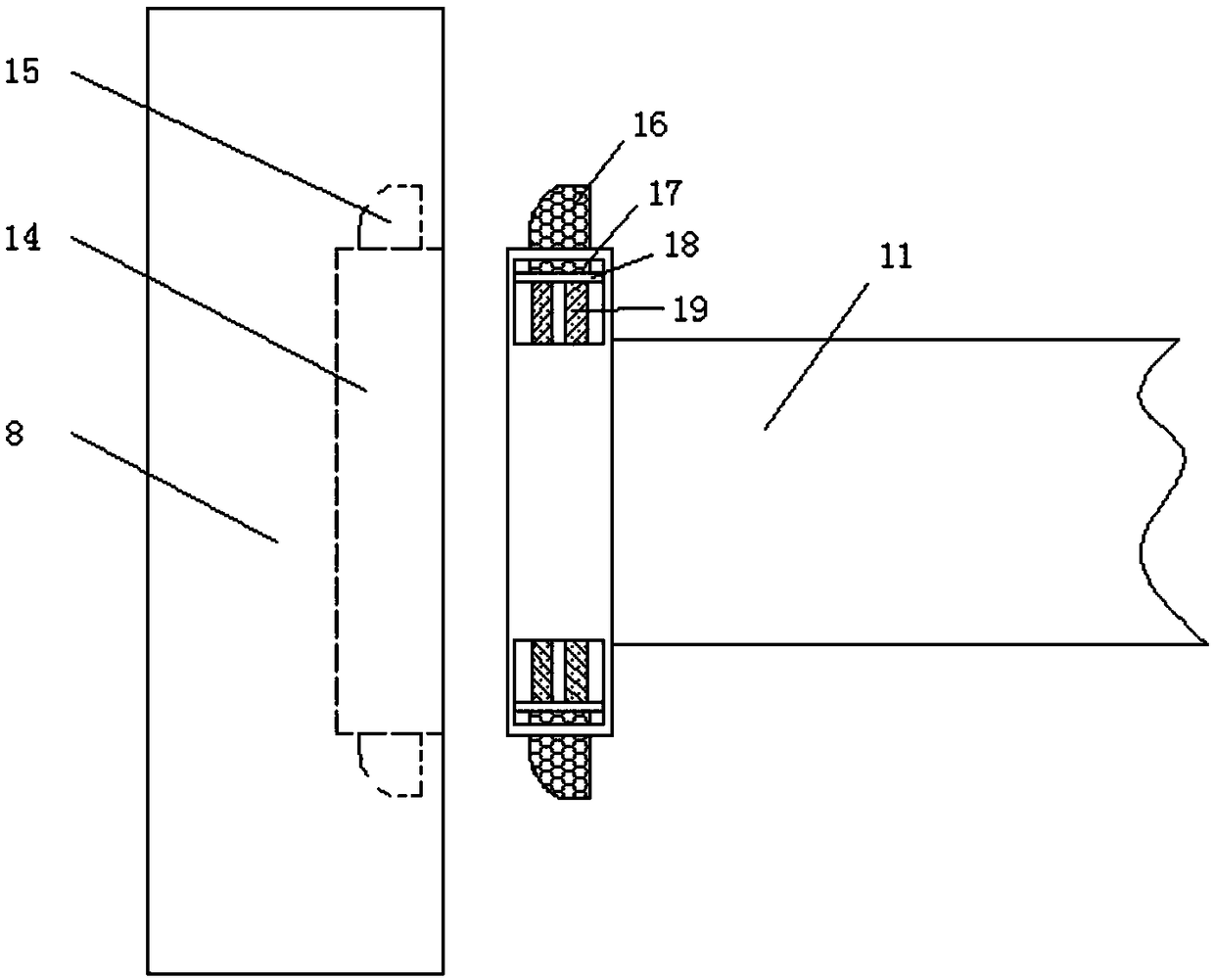

[0029] Embodiment three, refer to image 3 One side of the fan blade mounting plate 8 is provided with a connecting slot 14, and the inner wall of the connecting slot 14 is provided with a fixed pin groove 15, and the outer wall of one end of the rotating shaft 11 is provided with a mounting groove 17, and the inner wall of the mounting groove 17 is connected by an elastic member 19. There is a movable plate 18, one side of the movable plate 18 is welded with a fixed pin clamp 16, and the fixed pin clamp 16 is clamped in the fixed pin groove 15, when the fan blade mounting plate 8 is installed, only one end of the rotating shaft 11 needs to be Just insert it into the connection slot 14. Since the edge of the fixed pin card 16 is an arc-shaped structure, when the rotating shaft 11 is inserted into the connecting slot 14, the fixed pin card 16 on the rotating shaft 11 will automatically compress the elastic part 19, and shrink toward the inside of the rotating shaft 11 until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com