Differential mechanism assembly of automobile front-wheel drive transmission

A differential and transmission technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of complex assembly process, unreasonable structure, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

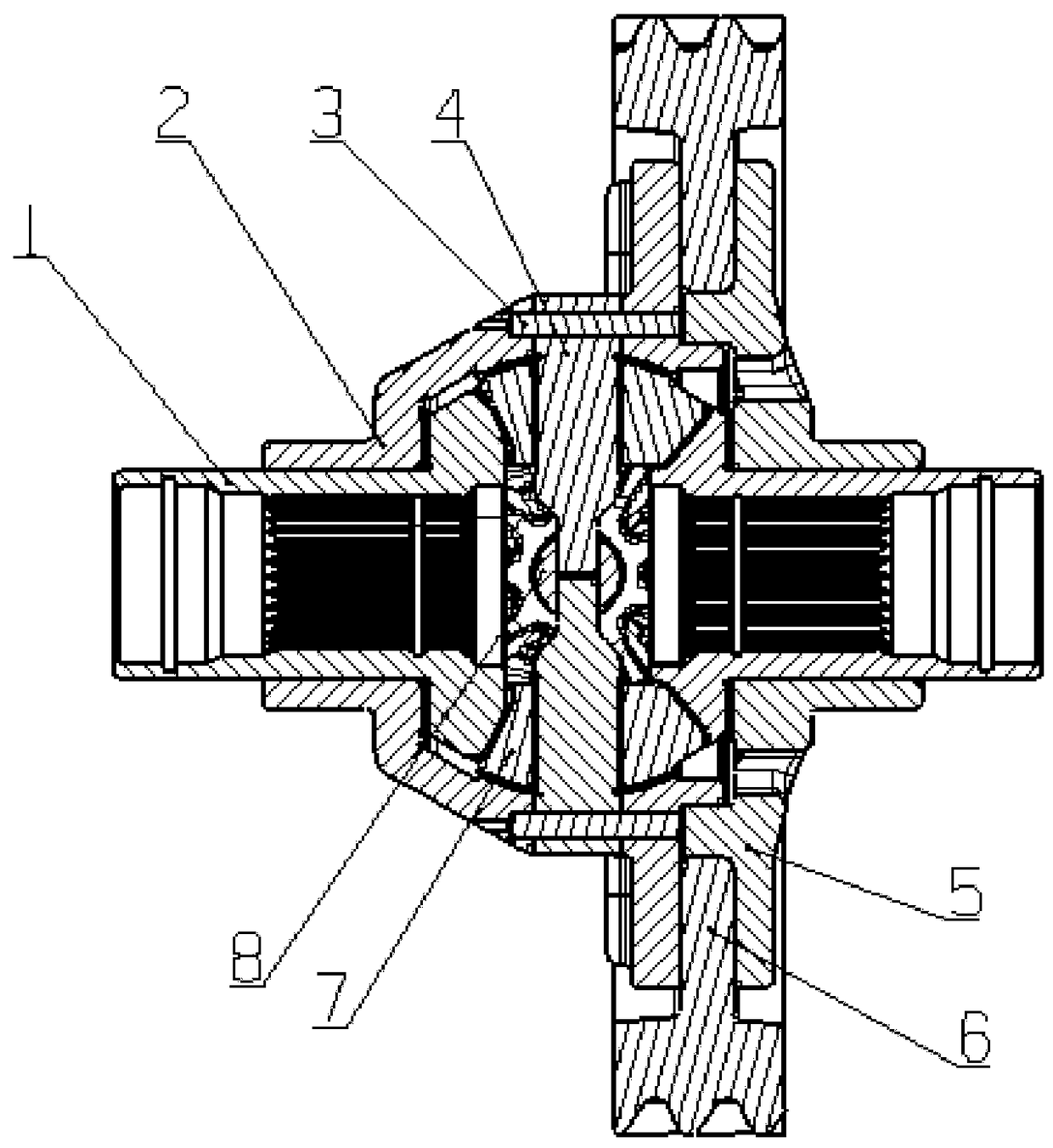

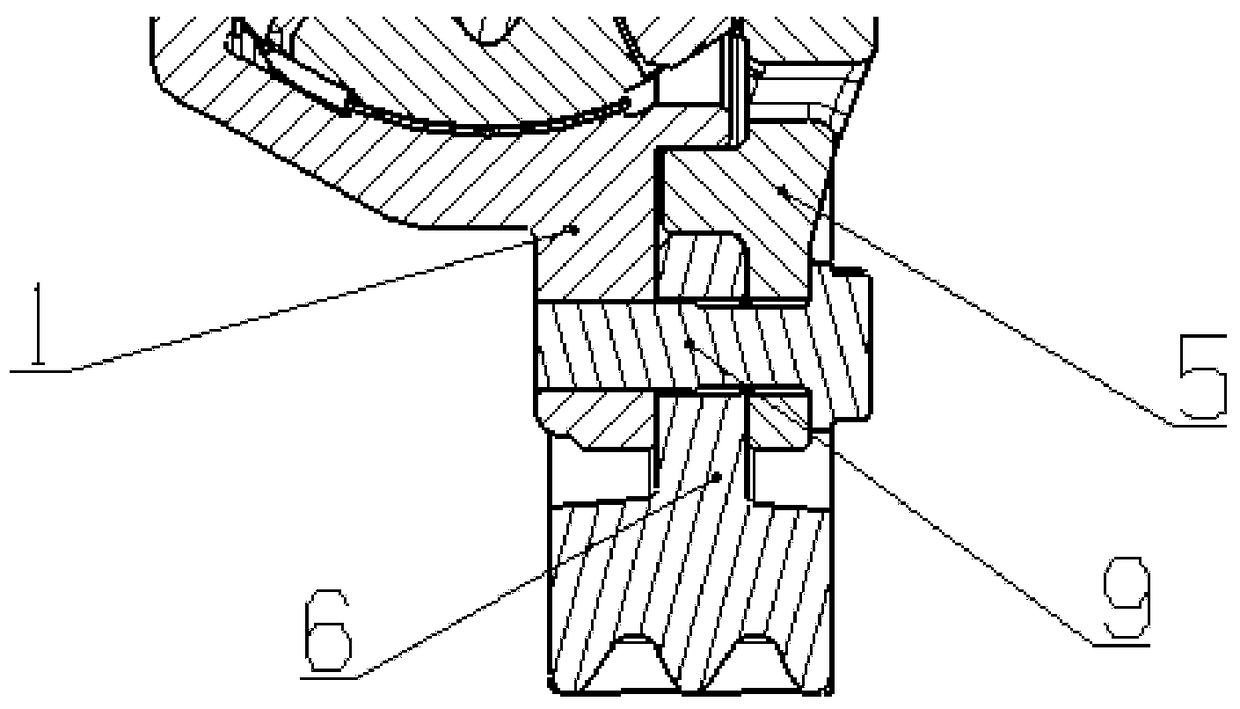

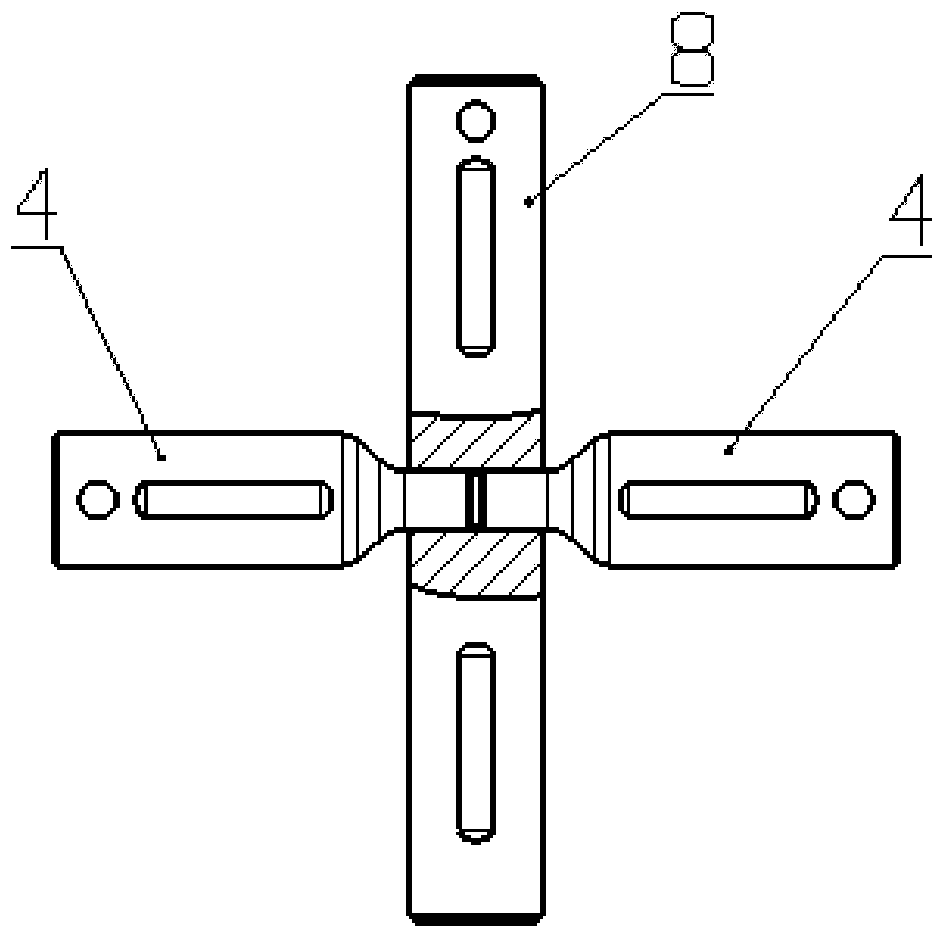

[0019] see Figure 1 to Figure 5 , an embodiment of a differential assembly of an automobile front drive transmission, including a differential housing 2, a housing end cover 5, four planetary bevel gears 7, two side gears 1 and planetary gear shafts, and a Main reduction gear 6. The opposite ends of the differential case 2 and the differential case cover 5 are respectively provided with extension sections for installing bearings, so that the differential can be supported in the transmission case through the bearings. Axial through holes are provided on the extension sections of the differential case 2 and the differential case cover 5 where the bearings are installed, and the opposite ends of the differential case 2 and the case end cover 5 are respectively provided with Assembling the limiting flange, wherein, the inner peripheral wall of the assembling limiting flange of the housing end cover 5 and the outer peripheral wall of the assembling limiting flange of the differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com