Discharging method for bottom condensate water in volute for fan

An inner bottom, condensate technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem of difficult discharge, achieve the effects of small investment, reasonable condensate discharge, and simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

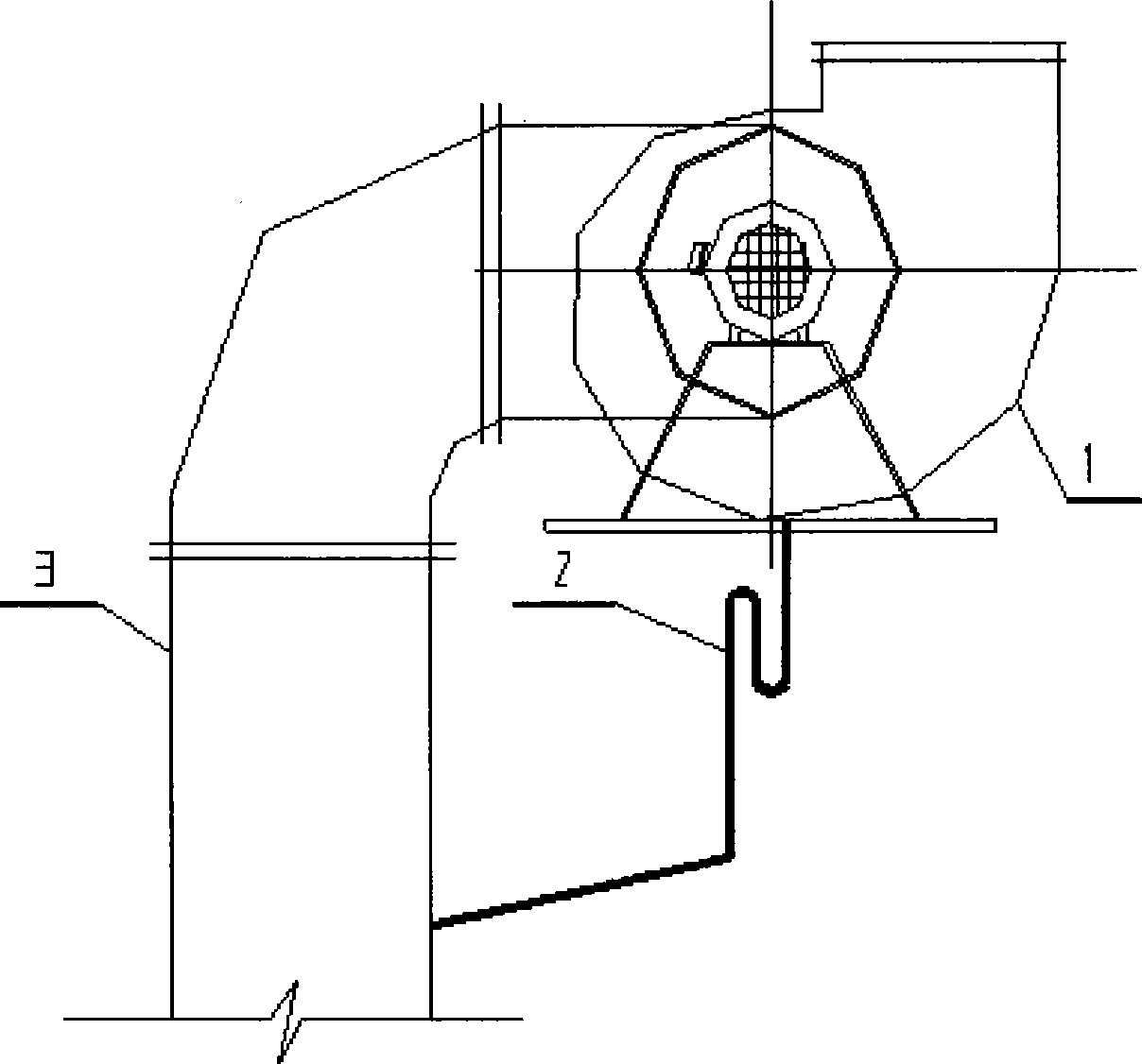

[0013] First install a water trap 2 at the bottom of the volute of the fan 1, the pressure formed by the water seal height of the water trap is greater than the wind pressure in the fan, and then discharge the water from the water trap to the air inlet pipe 3. When the condensed water is generated when the fan discharges steam, humid air or wet waste gas generated on the pool or waste liquid pool upwards, the condensed water can be automatically drained through the water seal and discharged into the air inlet pipe, and finally flow back to the pool. This embodiment does not cause air to flow through here, and also solves the discharge outlet of condensed water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com