Distributed finned heat exchanger

A heat exchanger and fin technology, applied in the field of heat dissipation equipment with novel structure, can solve the problems of waste, high energy consumption, waste of material weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

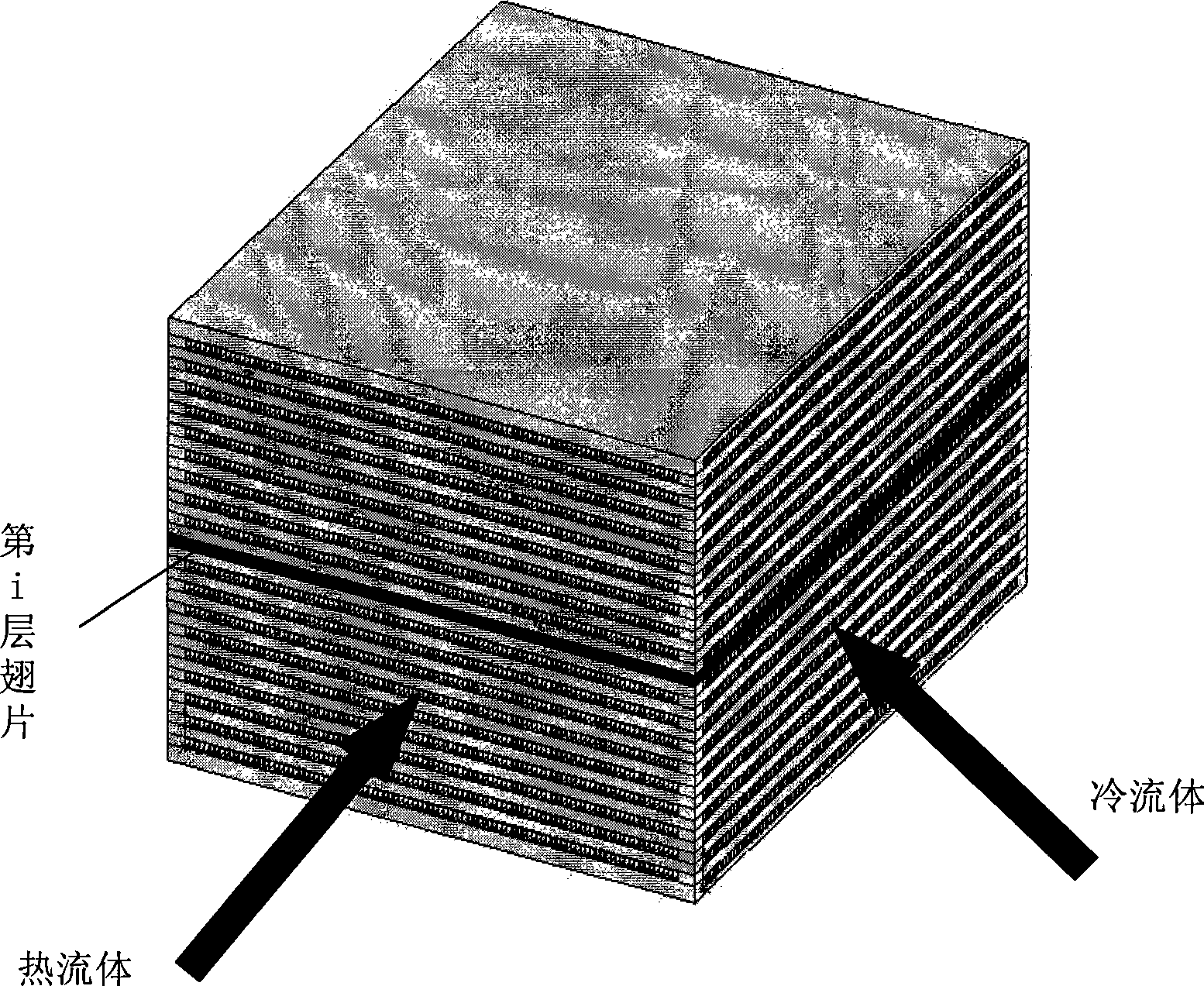

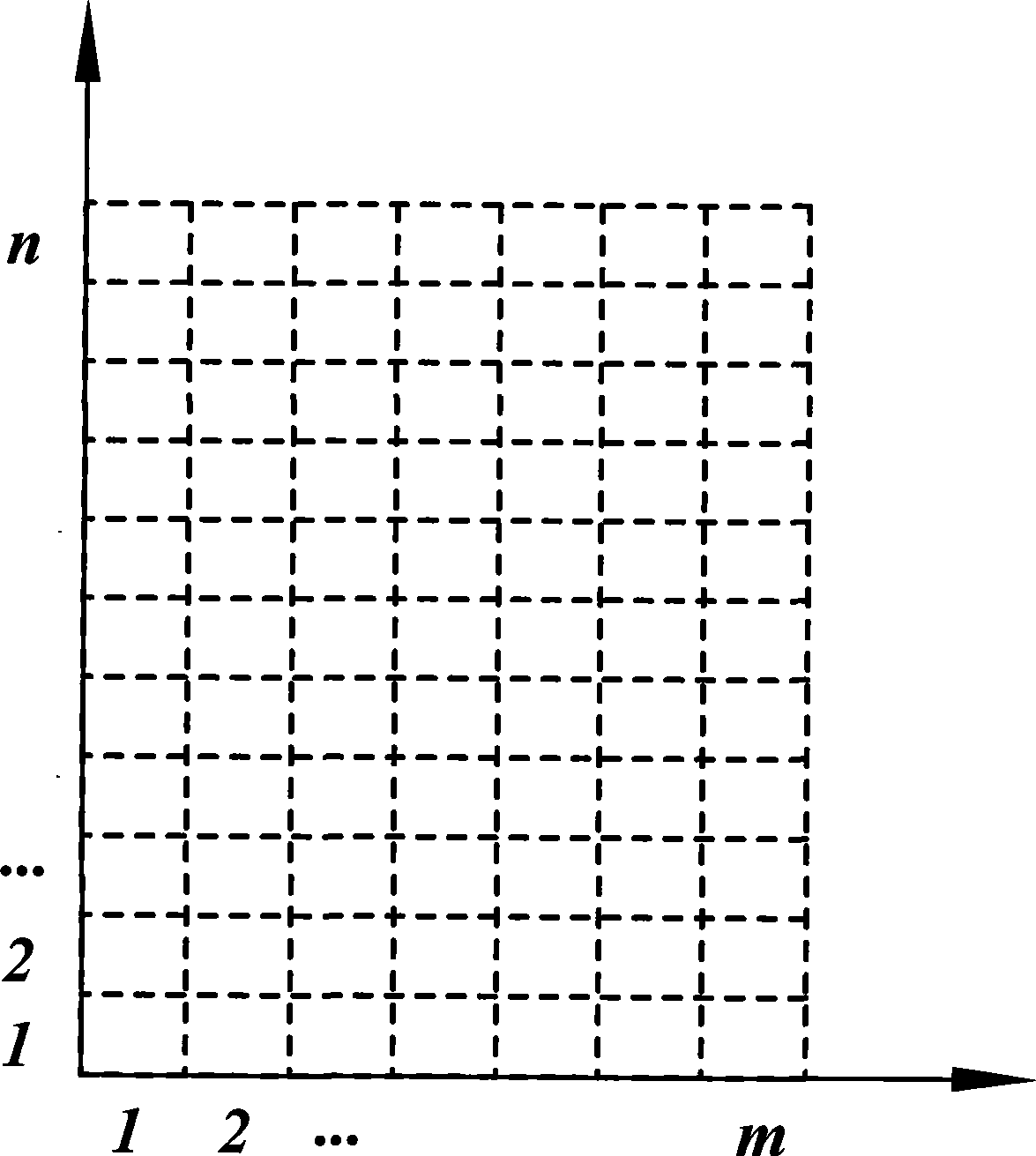

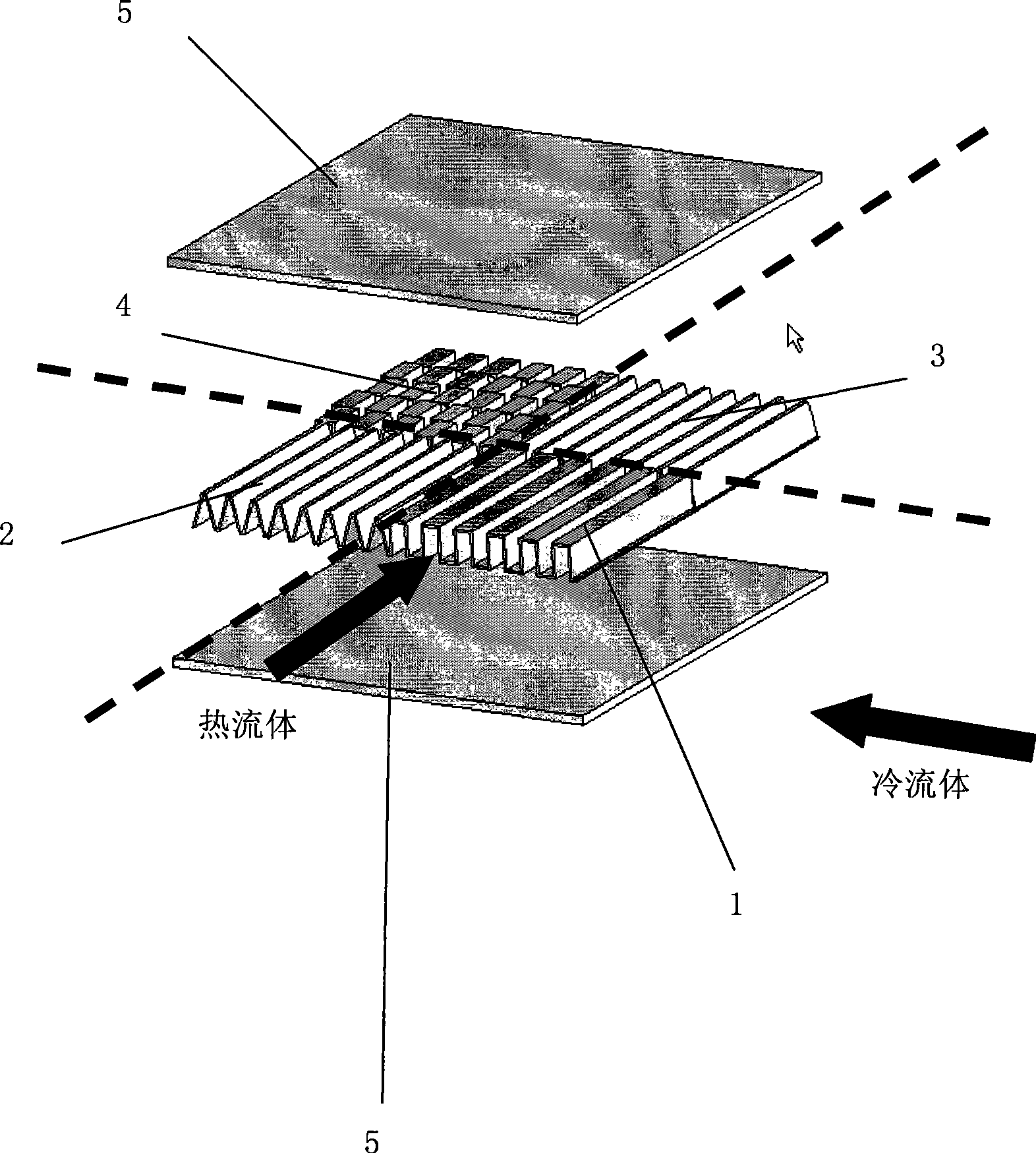

[0018] The present inventor has carried out in-depth research on the design method of the compact heat exchanger, and proposed a new mathematical model—distributed parameter model. The characteristics of this model are: the compact heat exchanger is divided into several micro-element control bodies according to the fin scale, and the distribution of temperature, pressure and other thermal parameters of each micro-element control body is solved by the energy balance equation of the control body . Since the characteristic scale used in the calculation of the mathematical model is equal to the scale of the fins in the physical model of the heat exchanger, compared with the CFD (Computational Fluid Dynamics) method, the physical meaning of the micro-element control body is more clear, and the existing The heat transfer and resistance performance data of the fins, the calculation speed has a breakthrough improvement compared with the CFD method, and the optimal design of the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com