Surface tension tester and method

A surface tension and tester technology, used in scientific research institutions and university laboratories, can solve problems such as the difficulty of controlling the single largest bubble in the capillary, affecting the test speed and work efficiency, and the troublesome pressure reading of the manometer, so as to improve the test speed and Work efficiency, reading pressure is convenient and accurate, easy to grasp the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

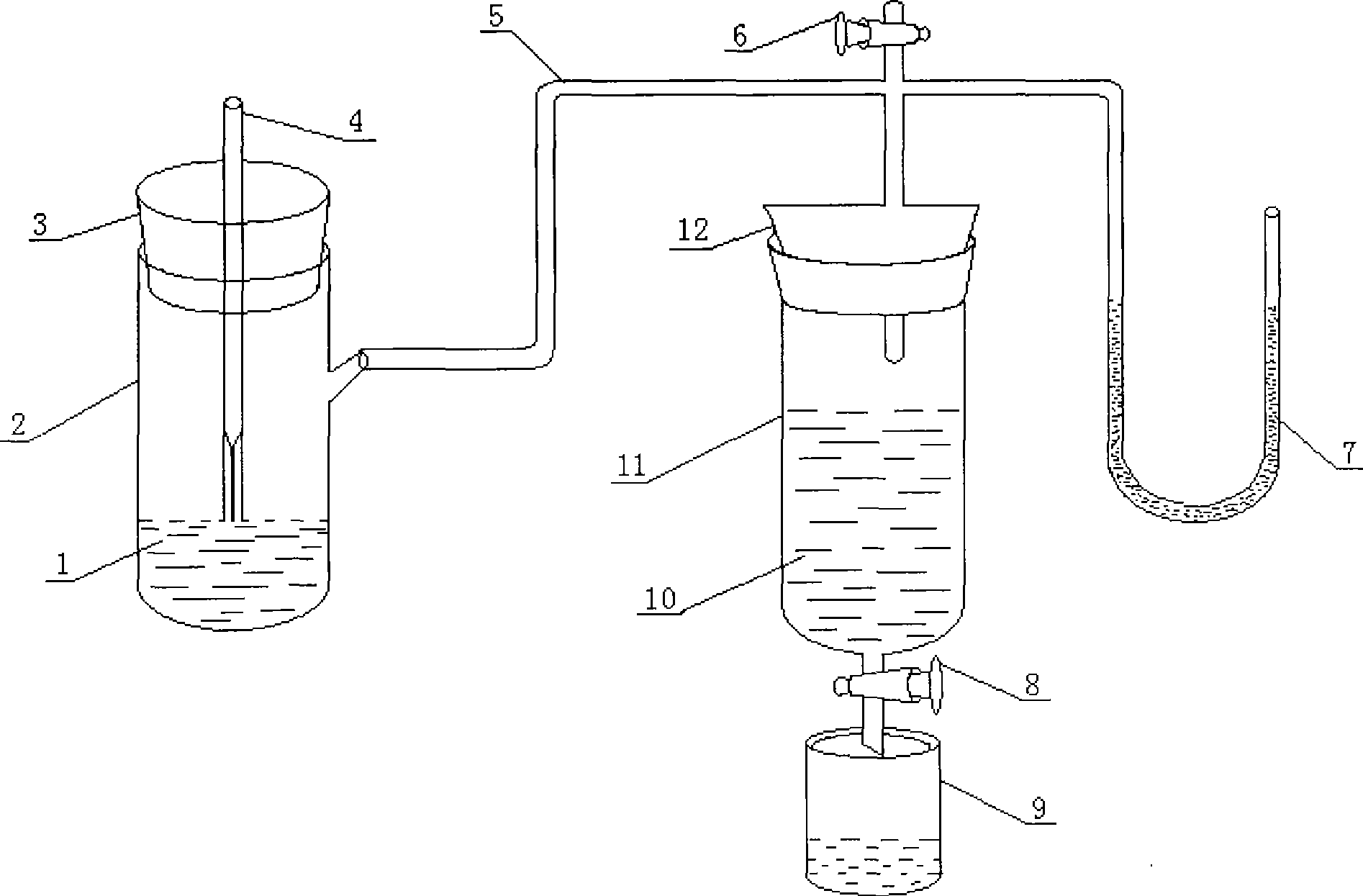

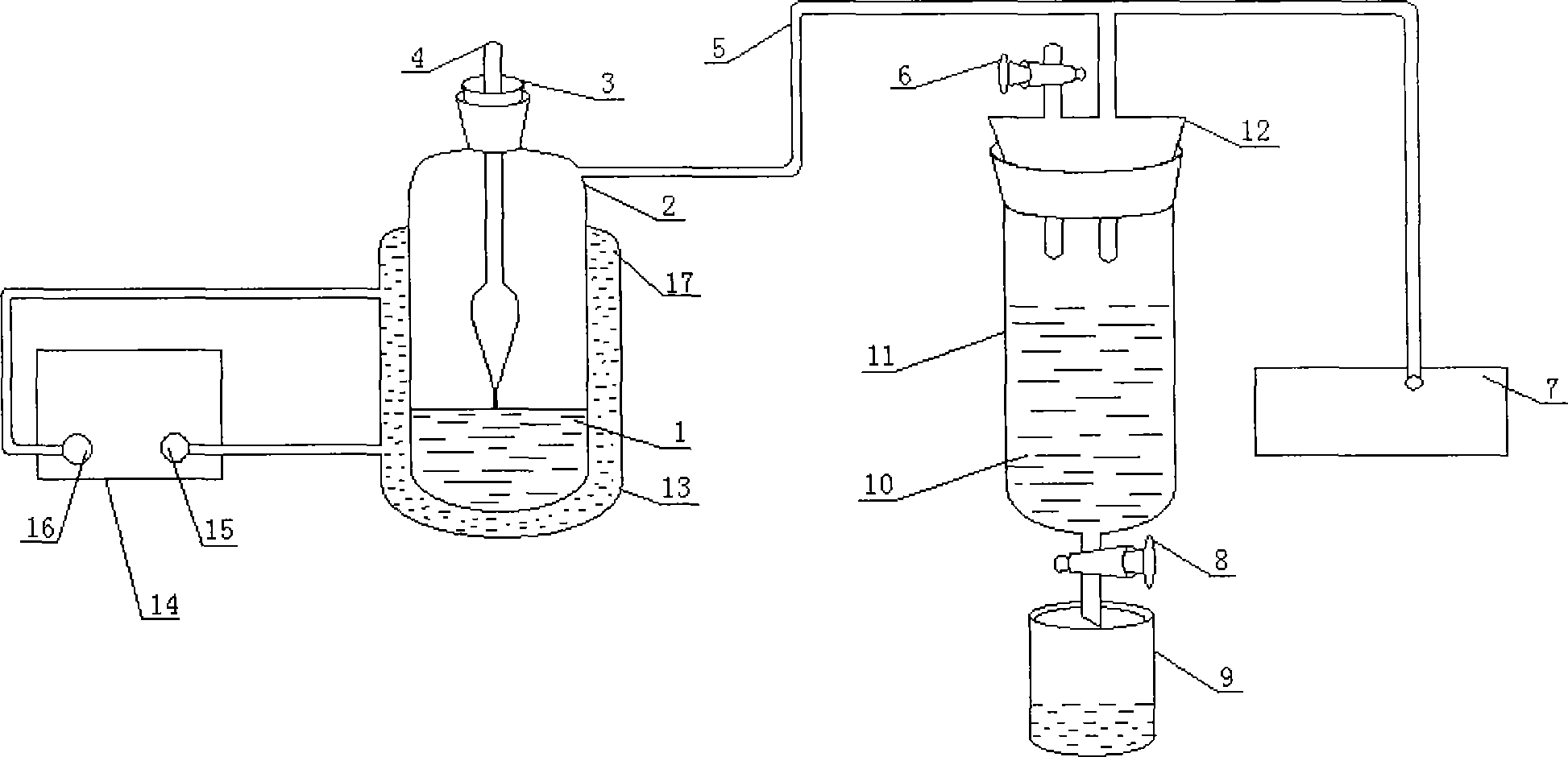

[0024] A preferred embodiment of the present invention is described in detail with reference to the accompanying drawings as follows:

[0025] See figure 2 , The surface tension tester includes a liquid measuring container 2 for storing the solution to be tested 1, a capillary tube 4 with the tip tangent to the liquid surface to be tested, a decompression device 11, and a capillary tube 4 vertically inserted into the liquid measuring device 2 The rubber tube 5 is connected to the pressure gauge 7 of the liquid measuring container 2 and the pressure reducing device 11, and the liquid measuring container 2 is equipped with a thermostat.

[0026] The structure of the thermostatic device is: the liquid measuring container 2 is used as an inner tube, and an outer tube 13 is sheathed. The outer tube 13 is filled with circulating water 17, and the upper part of the outer tube 13 has a water outlet connected to a water inlet 16 of a constant temperature water tank 14. The lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com