Method for implementing data transmission between PLC of different brands

A data transmission and brand technology, applied in the direction of program control and electrical program control in sequence/logic controllers, can solve the problems of complex systems and difficult implementation, and achieve the effect of simple data transmission, simple implementation and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

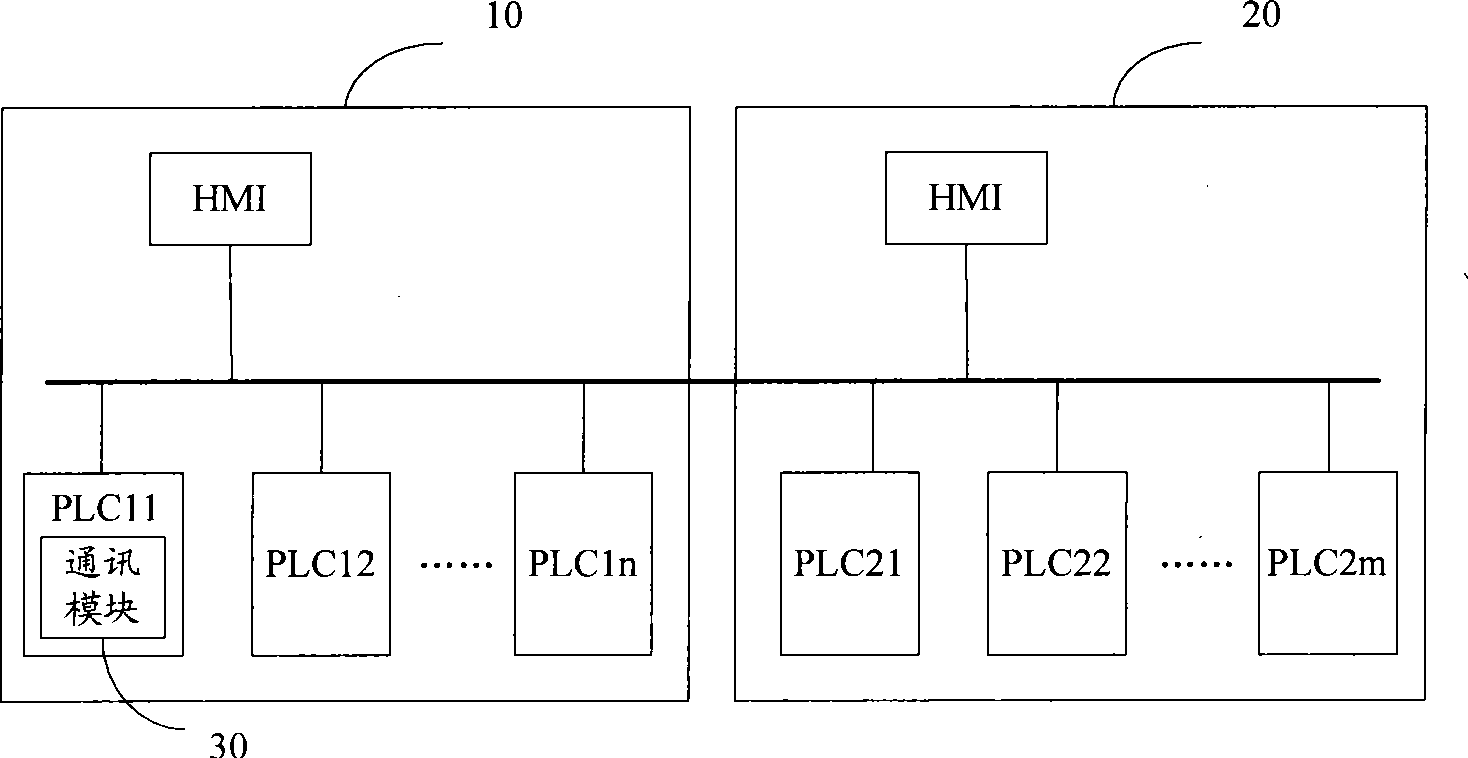

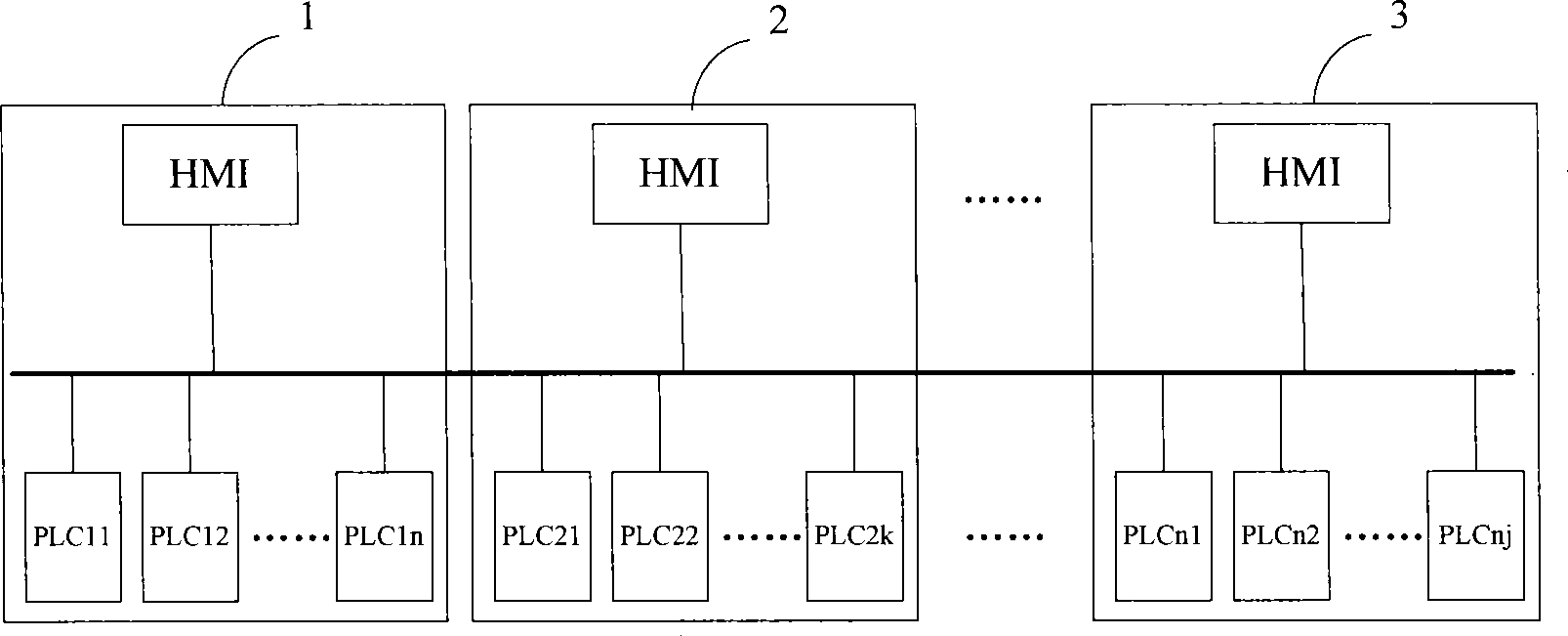

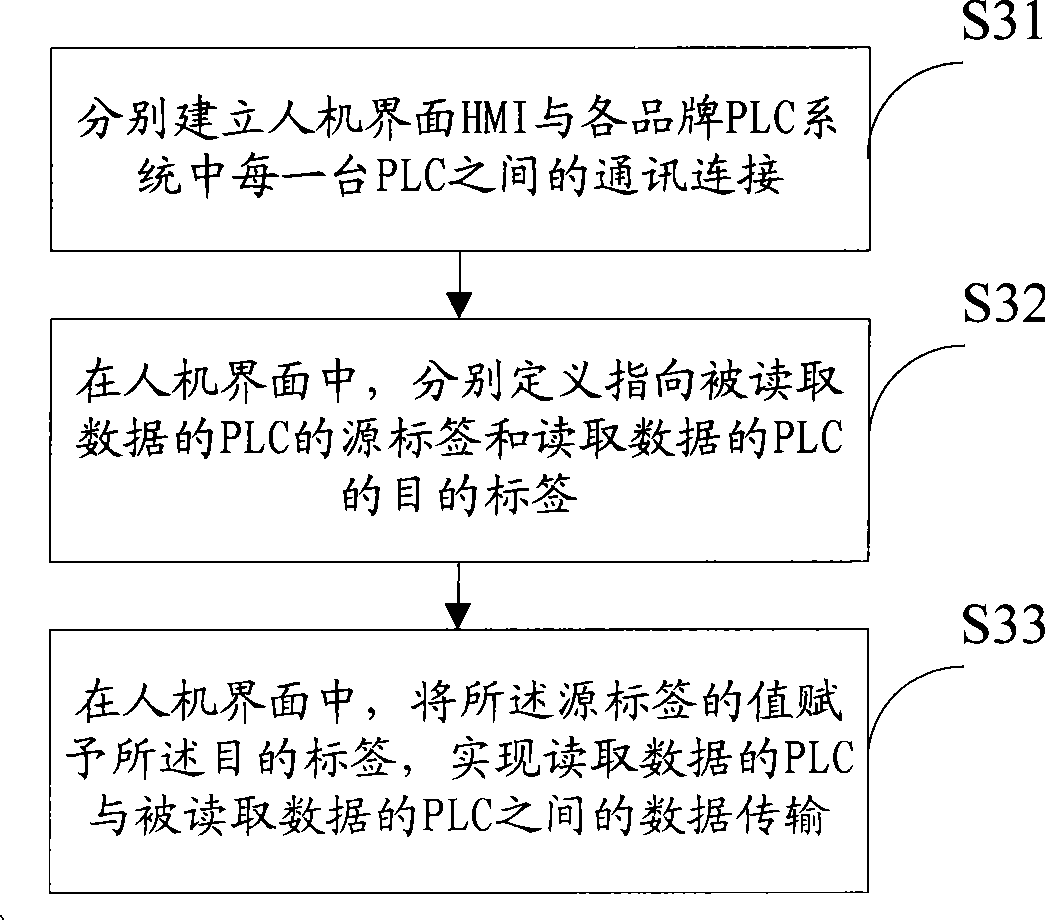

[0041] The method for realizing data transmission between PLCs of different brands described in the present invention establishes the communication connection between the man-machine interface and each PLC in the PLC system of each brand respectively. In the communication connection, for each PLC in the PLC system of each brand, the connection name between the PLC and the man-machine interface is defined respectively, and the connection name includes the network protocol supported by the PLC, the network address, data type and other information. By defining a source tag and a destination tag in the man-machine interface, the source tag points to the storage address where the read data is located in the PLC of the read data, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com