Brushless motor stator

A brushless motor and stator technology, applied in the shape/pattern/structure of winding insulation, magnetic circuit shape/pattern/structure, magnetic circuit static parts, etc. Good and other problems, to achieve the effect of improving the insulation effect and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

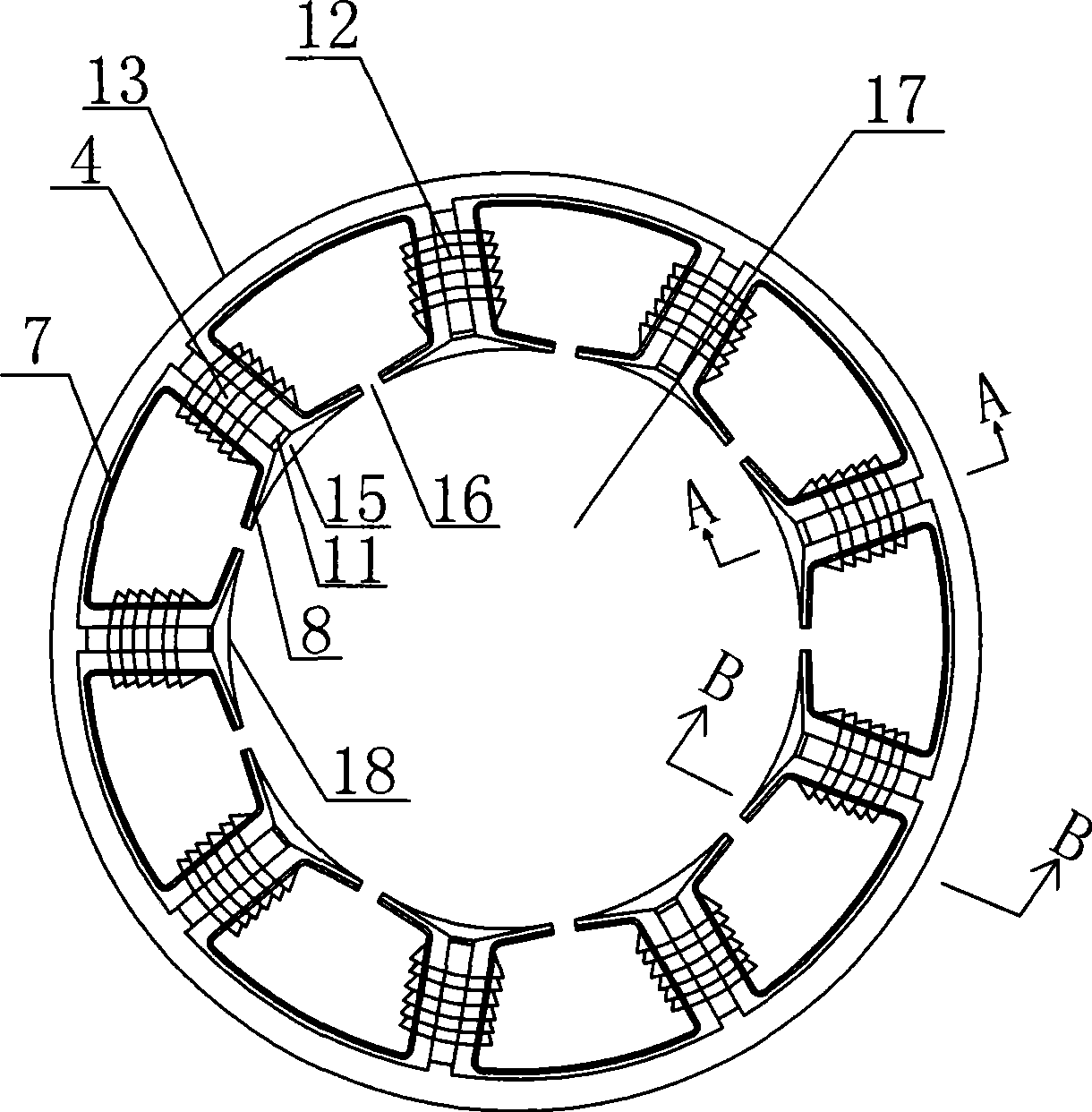

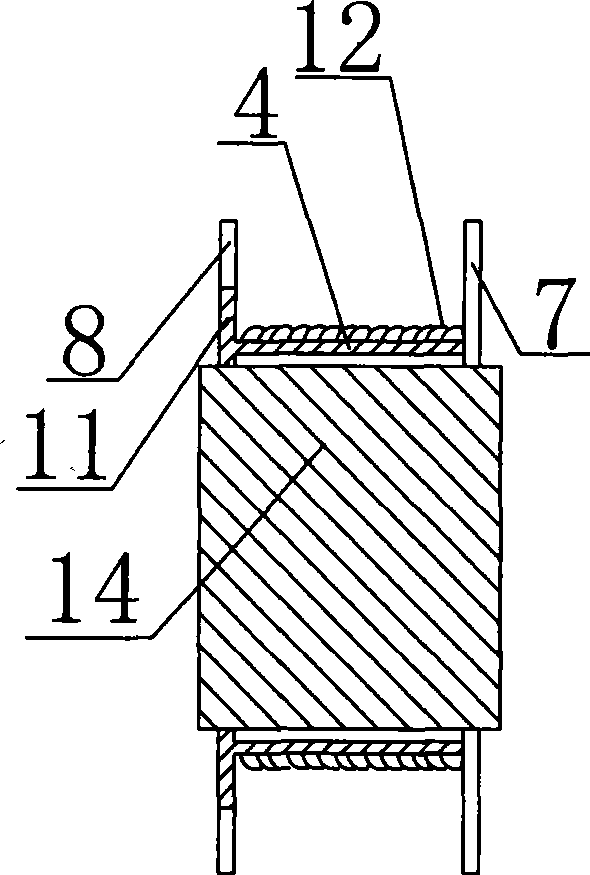

[0023] Example: such as Figure 1 to Figure 4 As shown, a brushless motor stator, the stator includes a cylindrical yoke 13 made of laminated steel plates, along the inner surface of the cylindrical yoke 13 radially provided with a plurality of protrusions 14 toward the center of the yoke At the end of the protruding portion 14, there are line retaining portions 15 extending to both sides of the protruding portion 14 respectively. There is a gap 16 with the same width between them, the protruding part 14 is used as a winding support for the winding coil, and the retaining part 15 can be used to limit the coil on the protruding part 14, preventing its deviation from contacting the rotor; all retaining parts The inner surface 18 of the wire portion 15 is formed with a rotor accommodating cavity 17 into which a rotor can be inserted.

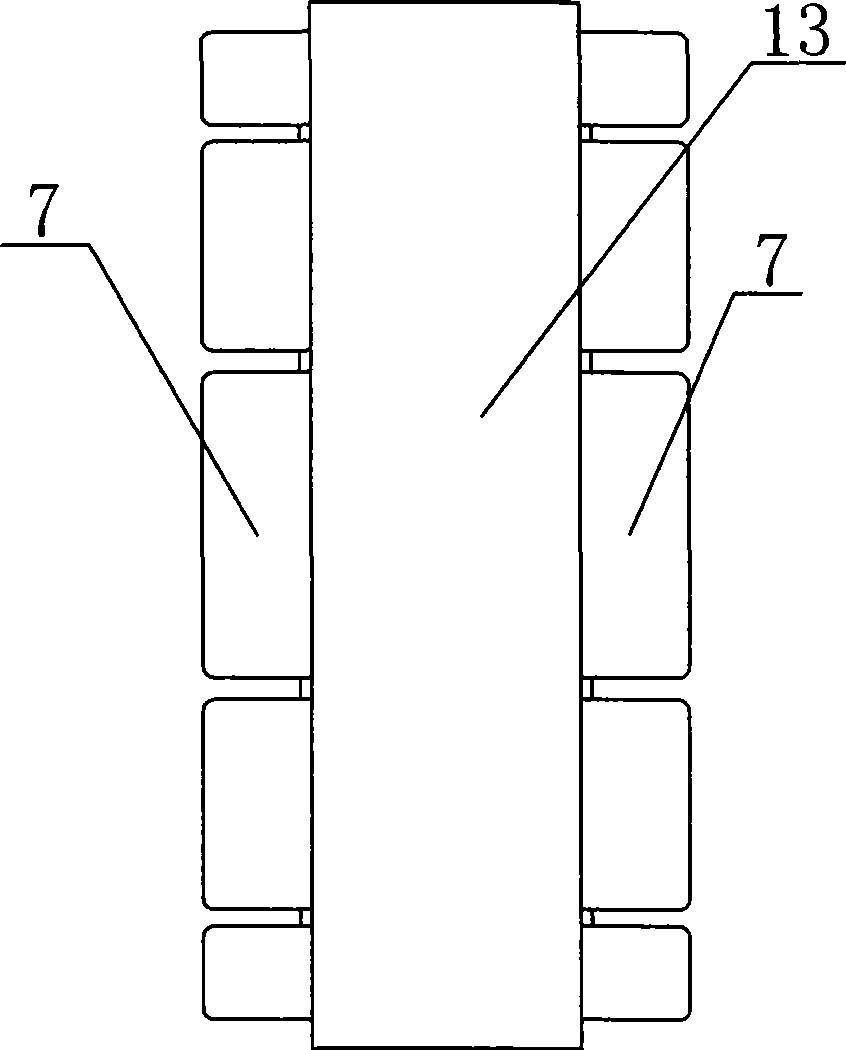

[0024] Two insulating skeletons with the same shape are inserted on the front and back sides of the cylindrical yoke 13. Several winding parts ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com