Liquid application apparatus and inkjet recording apparatus

一种涂敷装置、涂敷的技术,应用在对表面涂布液体的装置、着墨装置、涂层等方向,能够解决损伤底基膜、没有提供防止效果、变差等问题,达到良好接触的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0134] According to the composition shown in Table 1, a treatment liquid (Example 1) was prepared. Accordingly, the physical properties of the treatment liquid thus obtained (Example 1) were measured, and the pH was 3.6, the surface tension was 28.0 mN / m, and the viscosity was 3.1 mPa·s.

[0135] (Table 1)

[0136] Material

example 2

[0138] Furthermore, according to the composition shown in Table 2, a treatment liquid containing a surfactant was prepared (Example 2). Accordingly, the physical properties of the treatment liquid thus obtained (Example 2) were measured, and the pH was 3.5, the surface tension was 18.0 mN / m, and the viscosity was 10.1 mPa·s.

[0139] (Table 2)

[0140] Material

weight%

2-pyrrolidone-5-carboxylic acid (provided by Tokyo Chemical Industry Co., Ltd.

Division preparation) 10

Lithium hydroxide-hydride (by Wako Pure Chemical Industries, Ltd.

company preparation) 2

Olfine E1010 (manufactured by Nissin Chemical Industry Co., Ltd.

prepared) 1

3

Deionized water

84

[0141] The chemical formula of the fluorosurfactant 1 used in (Table 2) is as follows:

[0142] (C1)

[0143]

[0144] ink preparation

[0145] An example of preparation of the ink used in this embodiment is described below.

[...

no. 1 example

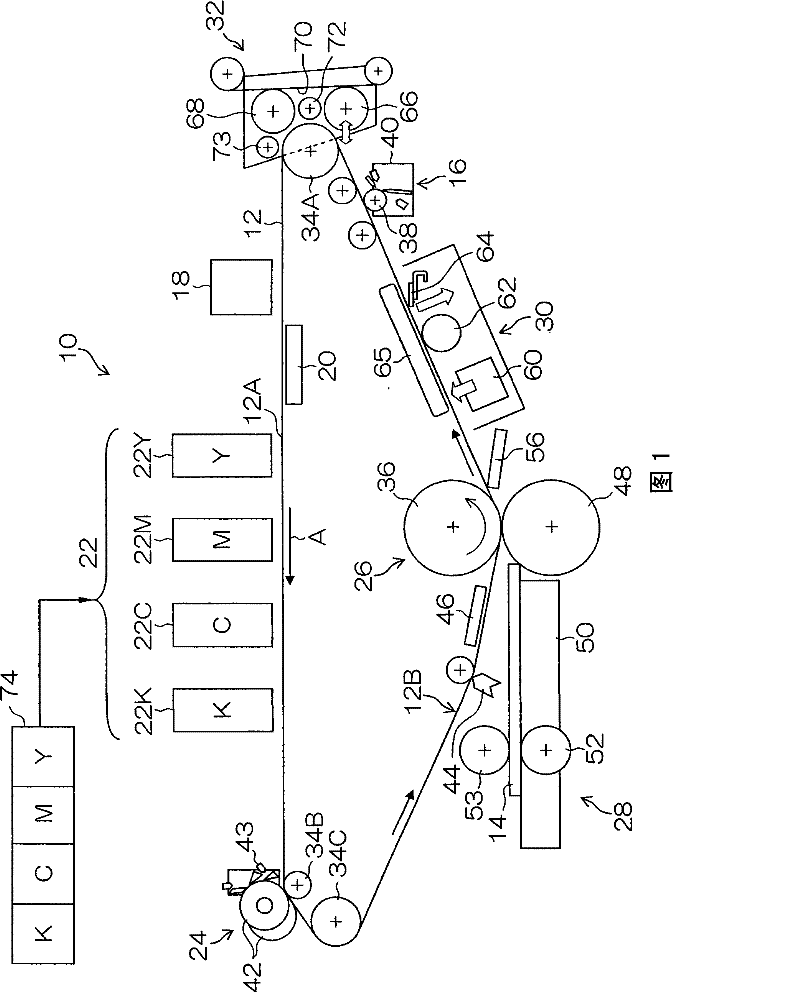

[0163] The liquid application apparatus 100 according to an embodiment of the present invention can be used in a coating method in which the treatment liquid which has been taken out from the liquid receiving pan due to the rotation of a circular coating drum is adjusted to a prescribed coating by a blade. amount, and then applied to the intermediate transfer body 12 (base material). In the following description, the liquid application apparatus 100 is described as an example of a direct gravure coater method using a gravure roll as a circular application cylinder.

[0164] FIG. 7 is a general perspective view of the liquid application device 100 seen obliquely from above, and Figure 8 is a side cross-sectional view of FIG. 7 .

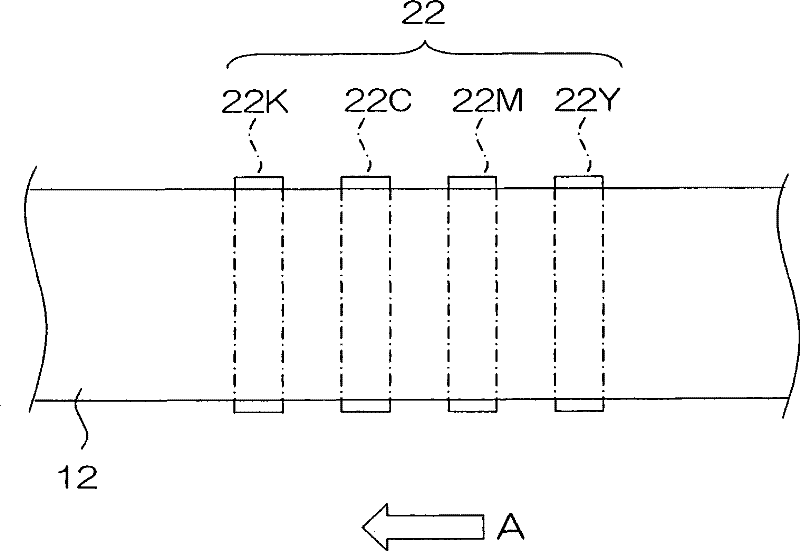

[0165] In FIGS. 7 and 8 , the intermediate transfer body 12 is transported in the arrow A direction. As shown in these figures, in the liquid application device 100, the upper portion of the circumferential surface of the application portion 38A of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com