Diagnosis device of chain slack for passenger conveying equipment and diagnosis method

A technology for passenger conveying equipment, diagnostic devices, applications in transport and packaging, energy efficiency of escalators, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

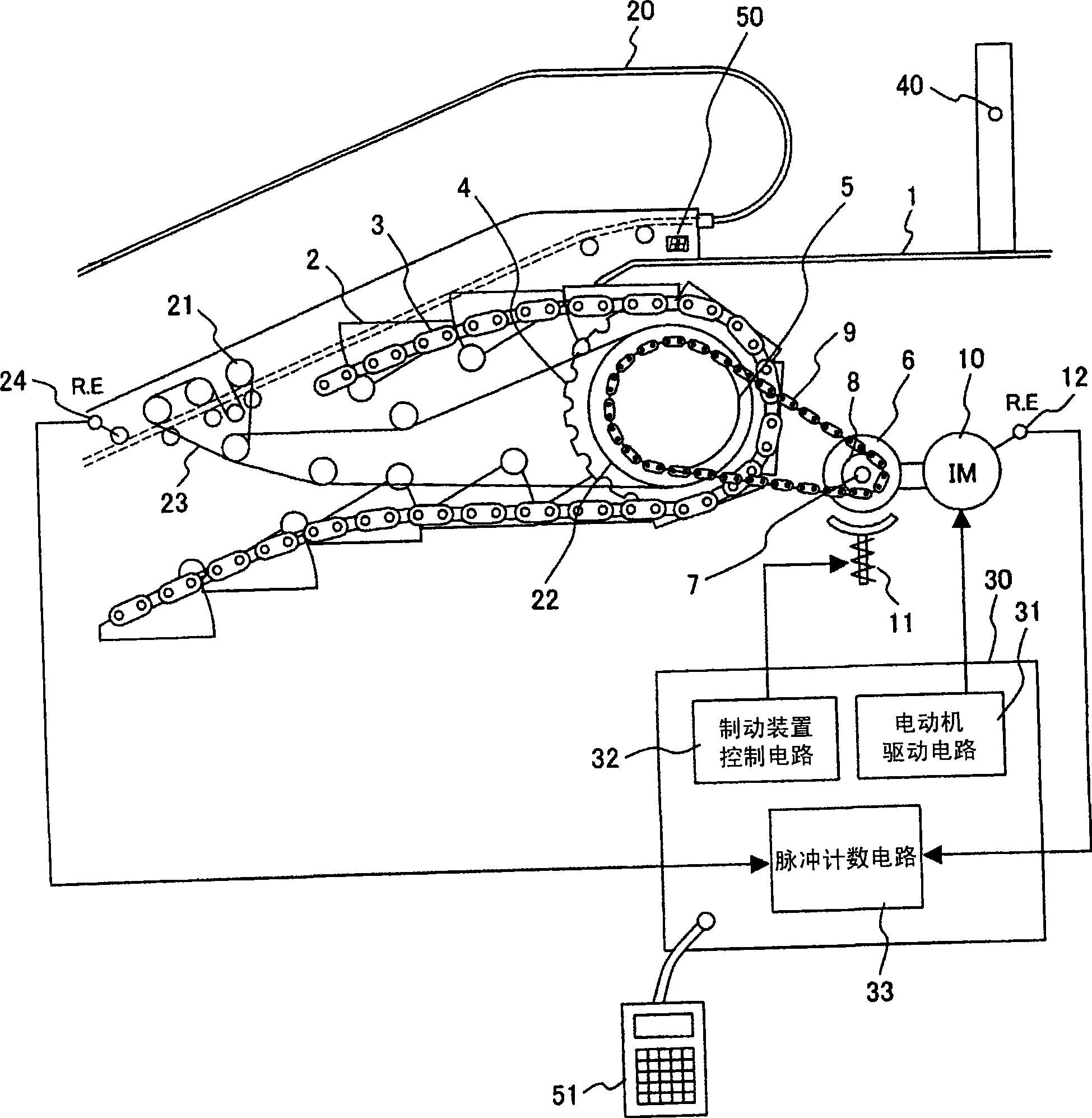

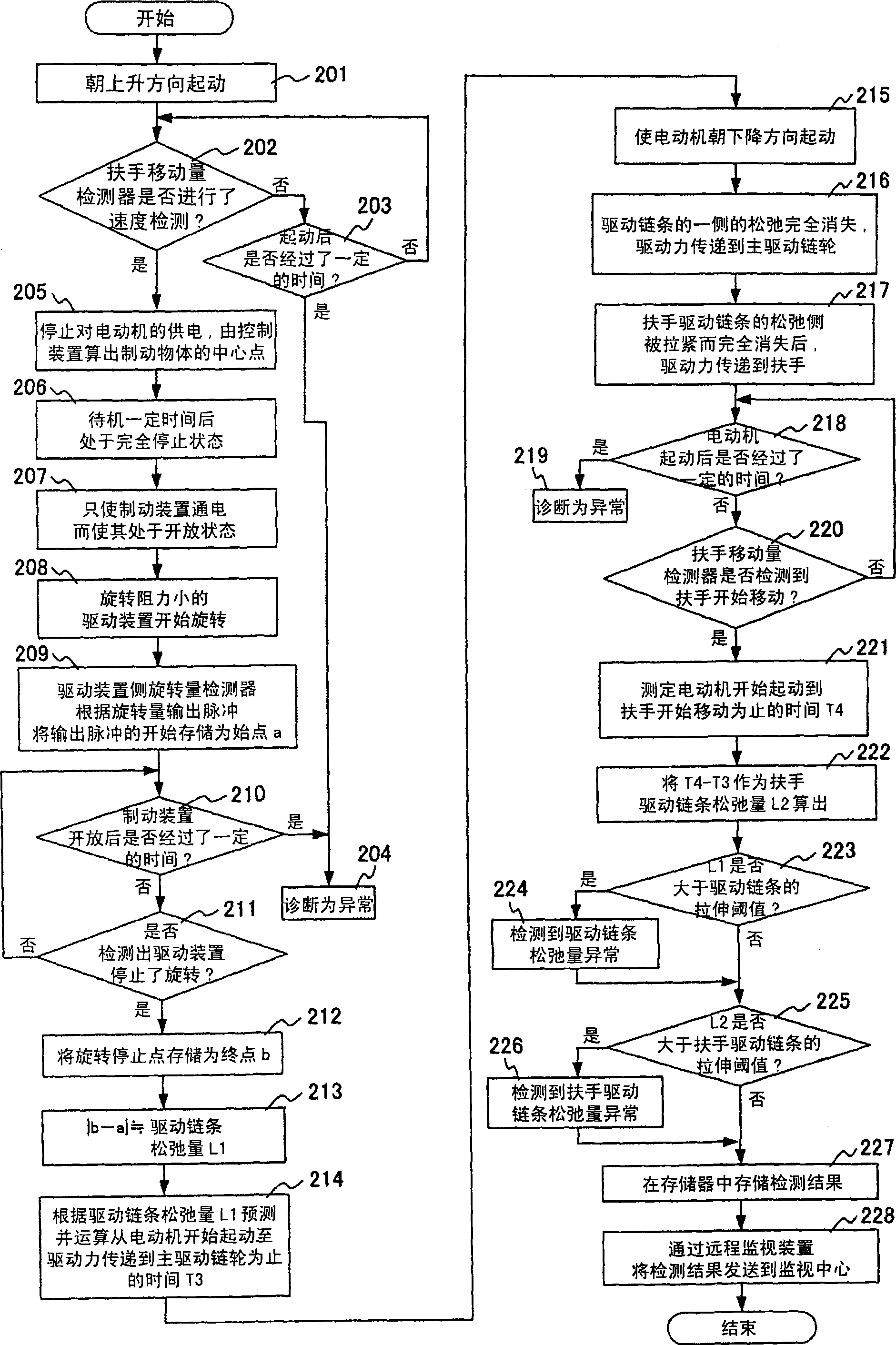

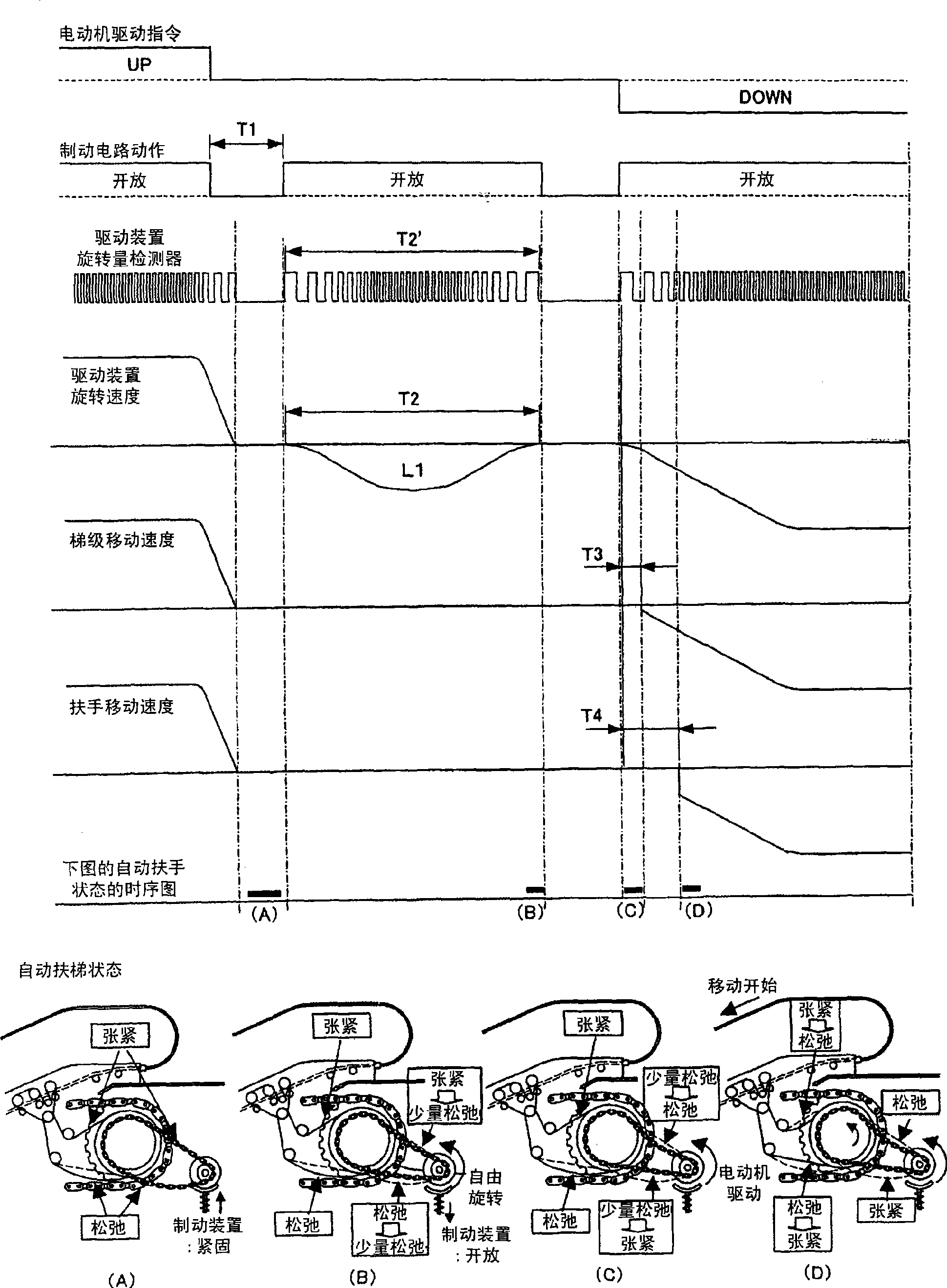

[0054] refer to figure 2 as well as image 3 The operation of the first embodiment will be described. figure 2 It is a flowchart of the slack amount diagnosis operation of the drive chain and the handrail drive chain in the escalator with the descending direction as the normal running direction. image 3 is to carry out figure 2 An operation explanatory diagram and a timing chart of the operation of each part at the time of the slack amount diagnosis are shown.

[0055]After receiving a diagnostic command for chain slack not shown in the figure, the escalator 1 is started in the upward direction by step 201, and then the driving force is transmitted to the handrail 20 in step 202, and is monitored by the handrail movement amount detector 24. Whether the movement of the escalator has started. When some abnormality occurs in the equipment of the escalator, and after a certain period of time, the driving force is still not transmitted to the handrail 20, thus causing the h...

no. 2 approach

[0067] Refer to the following Figure 4 The shown flow chart explains the second embodiment. This second embodiment is performed as figure 1 As shown, on the front side of the escalator entrance, a sensor 40 for detecting passengers getting in is provided, and when the sensor detects that a passenger is getting in, the escalator is started to carry out the second embodiment of the so-called automatic operation.

[0068] As described in the first embodiment, when the escalator is stopped because there are no passengers, the slack diagnosis of the drive chain 9 and the handrail drive chain 23 is performed. For this reason, in step 401, the passenger detection sensor 40 that is arranged on the front side of the escalator entrance and exit detects that the escalator is in the state of no passenger, and confirms that the escalator is in the standby state. Thereafter, in step 402, calculate according to the time information stored in the escalator control device 30 and the running...

no. 3 approach

[0071] Refer to the following Figure 5 The shown flow chart explains the third embodiment. The third embodiment is as figure 1 Shown is a third embodiment in which diagnosis is performed during maintenance work in an escalator provided with a status display 50 for displaying the status of the escalator and in which a maintenance portable terminal 51 is connectable to the escalator control device 30 .

[0072] In step 501, it is detected whether the escalator is in the state of maintenance work, and if it is not in the state of maintenance work, no diagnosis is performed. In step 502, in the maintenance work, after performing a specific password operation which is not used in general maintenance work, it proceeds to the slack amount diagnosis step 504 of the drive chain 9 and the handrail drive chain 23 . As a specific password operation, for example, a method such as continuously pressing the stop switch for 5 seconds, and then pressing the stop switch 5 times within 10 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com