Drum-type washer and dryer

A washer-dryer and drum-type technology, which is applied to other washing machines, washing machine appliances, household clothes dryers, etc., can solve problems such as increased washing water usage, prolonged washing time, and odor reliability, so as to prevent odors , Ensure reliability, and prevent impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. At the same time, it should be pointed out that the examples of the present invention do not limit the scope of the present invention.

[0030] (Example)

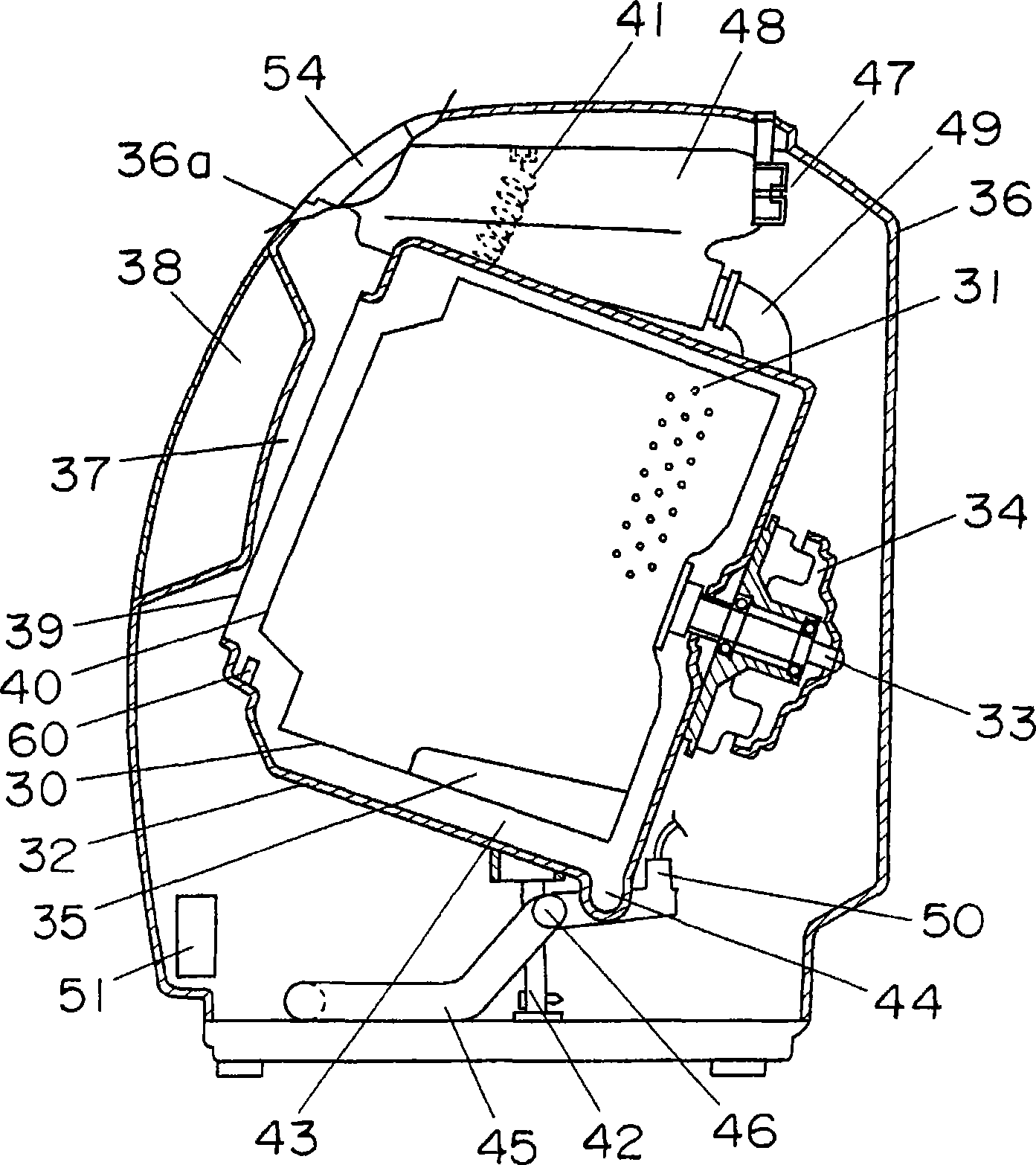

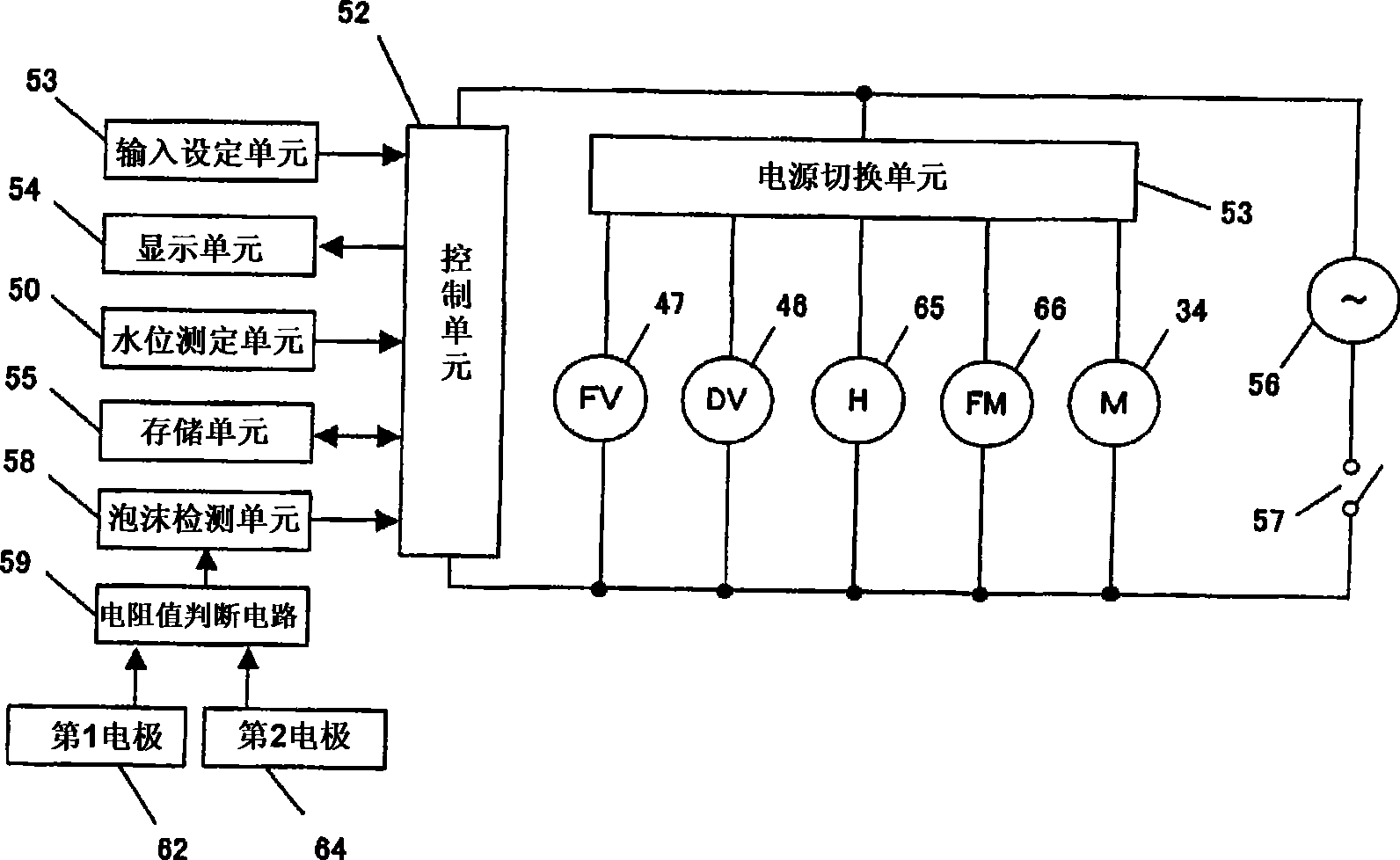

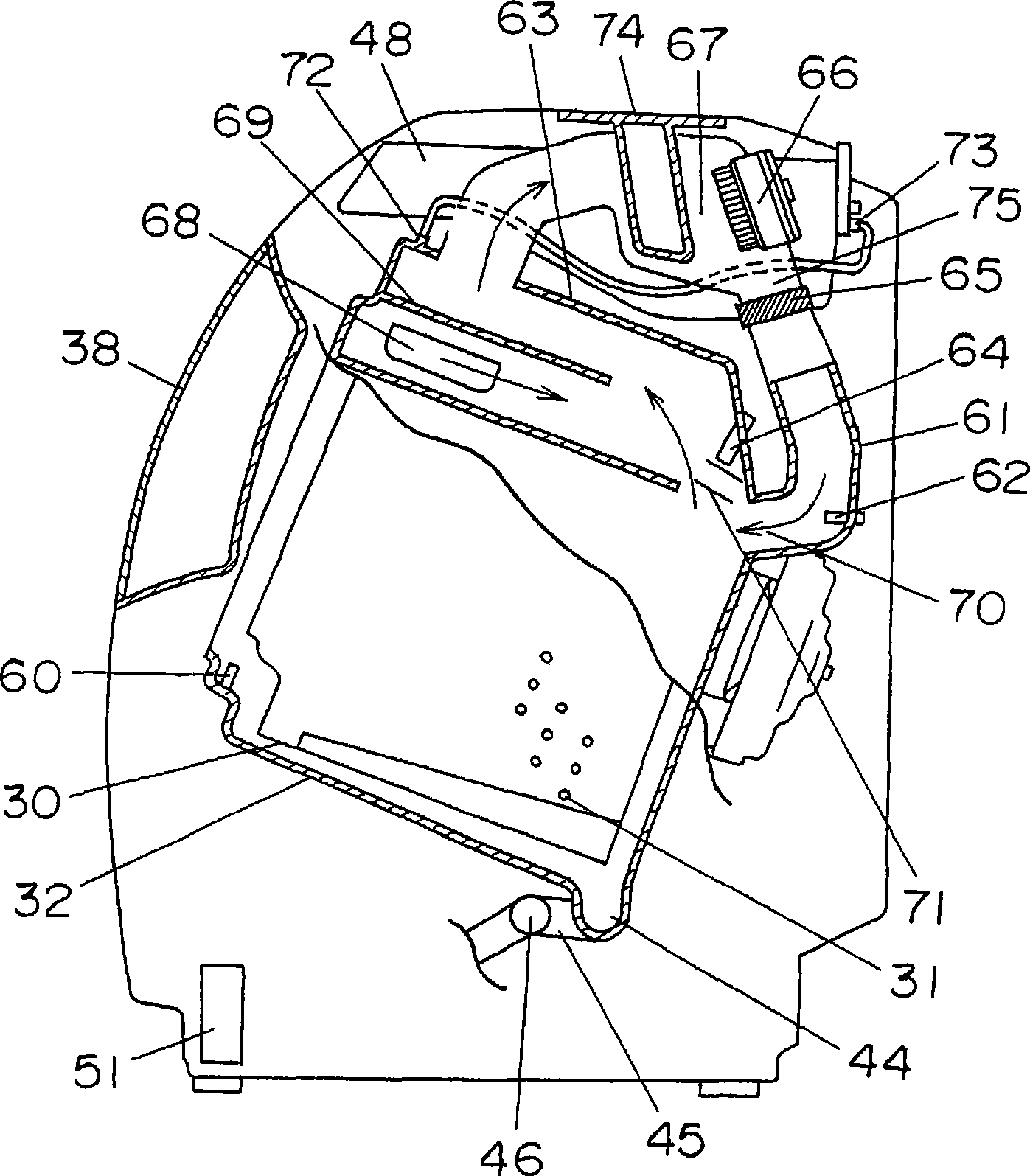

[0031] like figure 1 As shown in , the rotary drum 30 is made into a bottomed cylinder, and the entire wall of the cylinder is provided with many through holes 31, and is arranged in the water storage cylinder 32 in a freely rotatable manner. The rotation center of the rotary drum 30 is provided with a rotary shaft (rotation center shaft) 33 in an oblique direction, and the axis direction of the rotary drum 30 is inclined downward from the front side to the rear side. The above-mentioned rotating shaft 33 is connected with the motor 34 installed on the back of the water tank 3 , and the rotating drum 30 can rotate forward and reverse under the drive of the motor 34 . Several protruding plates 35 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com