Rotor type compressor

A compressor and rotor type technology, applied in the field of compressors, can solve the problems of increasing the dynamic balance of the compressor, difficult to remove the inertial force, increasing the friction and wear of the compressor, etc., and achieves the effect of reducing friction and wear and achieving good balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

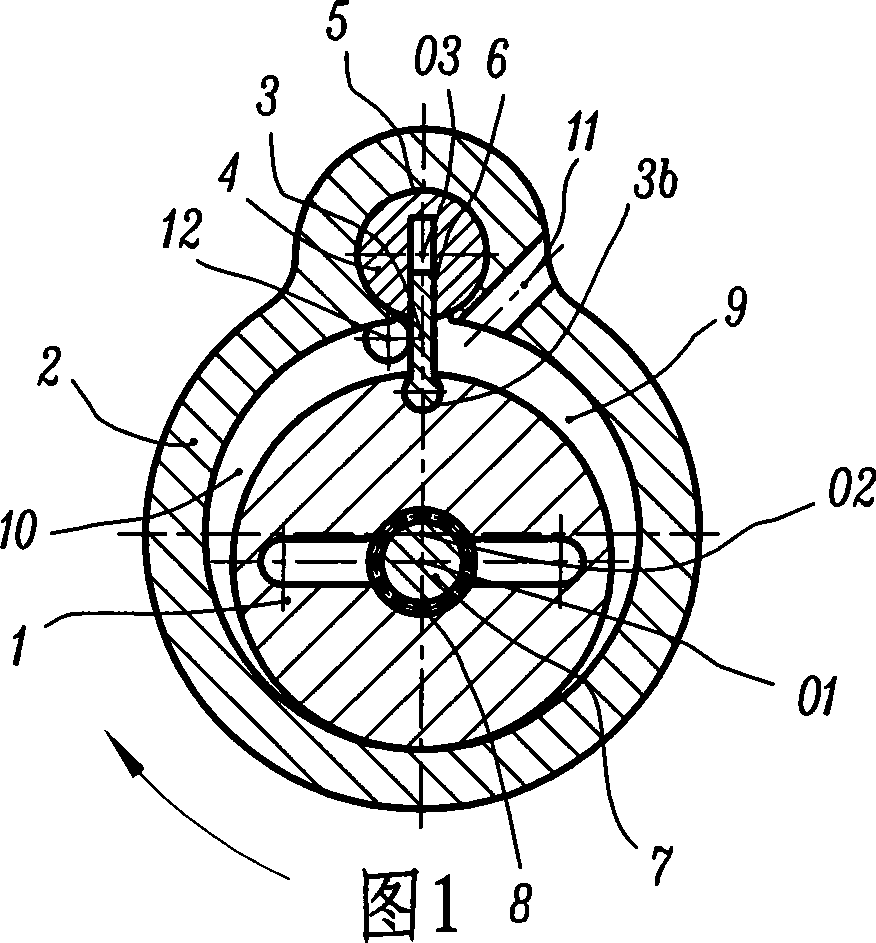

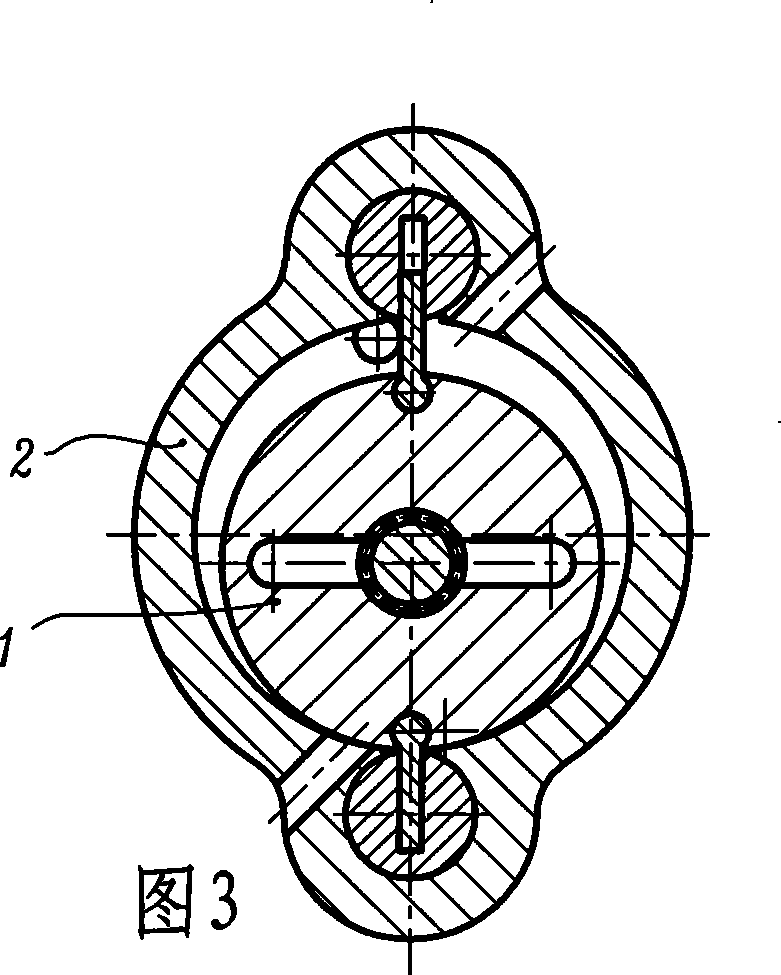

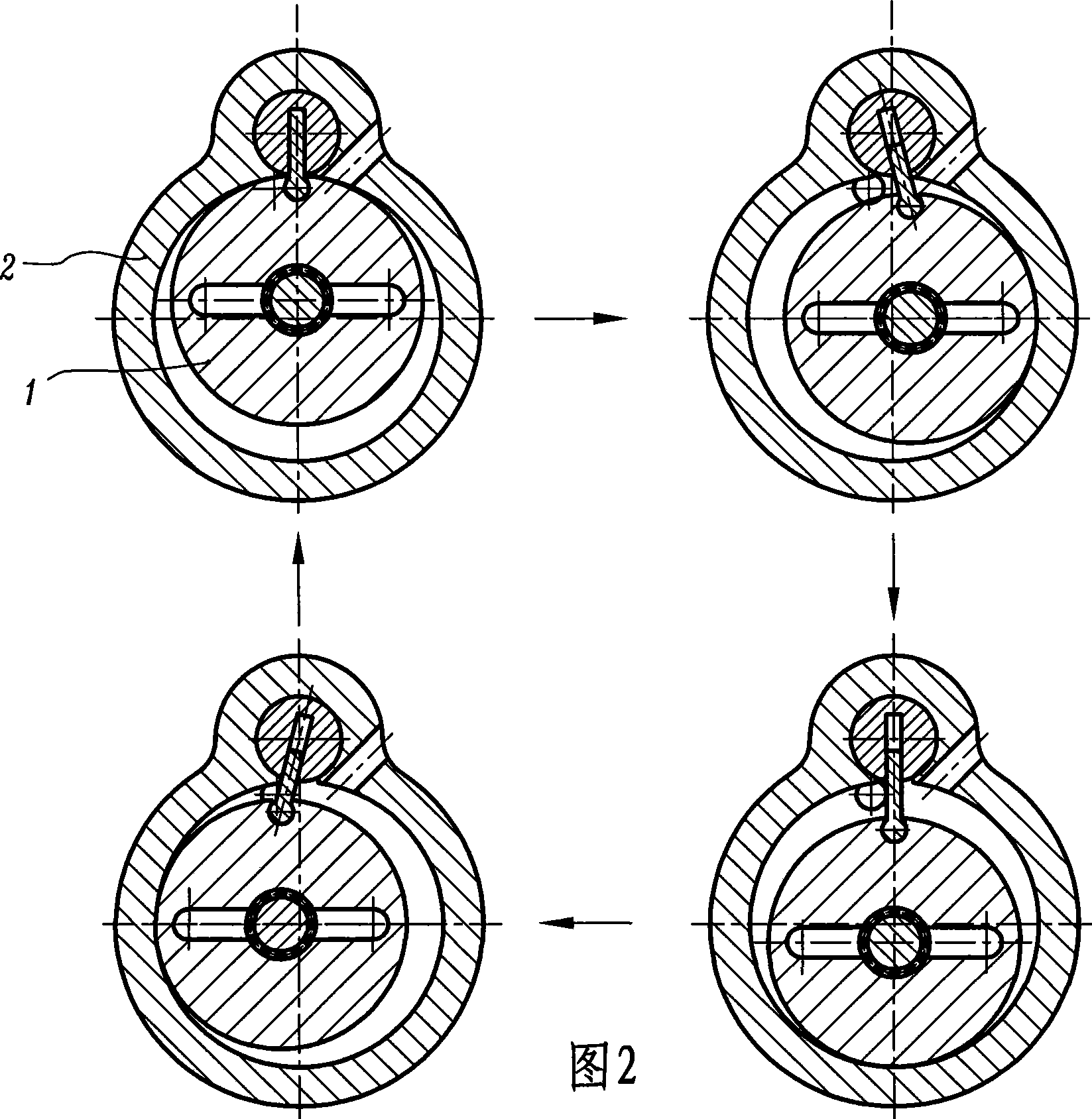

[0009] Fig. 1 and Fig. 2 show a cross-sectional schematic diagram and a working state diagram of an embodiment of a rotary compressor of the present invention. In this embodiment, the rotary compressor includes a rotor 1, a cylinder 2, a blade 3, a rotating column 4, and two end covers (not shown in the figure); the rotor 1 has a cylindrical The outer surface, the cylinder 2 has a circular hole-shaped inner hole surface, the inner end of the blade 3 is made into a cylindrical head shape, and the rest is flat, and the rotating column 4 has a cylindrical outer surface; the rotor 1 is offset In the cylinder 2, the rotor axis O1 and the cylinder axis O2 are arranged in parallel, the distance between the two axes is the eccentricity of the rotor 1 relative to the cylinder 2, and the outer surface of the rotor 1 is tangentially matched with the inner surface of the cylinder 2 (movement clearance is allowed or oil film gap); a cylindrical hole 3b parallel to the rotor axis O1 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com