Flame detector probe

A flame detector and flame detection technology are applied in photometry, combustion methods, and combustion chambers using electric radiation detectors. It can solve the problems of a large amount of waste residue, photoelectric cell damage, and inconvenient cleaning, and achieve good cooling effect. Improved service life and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

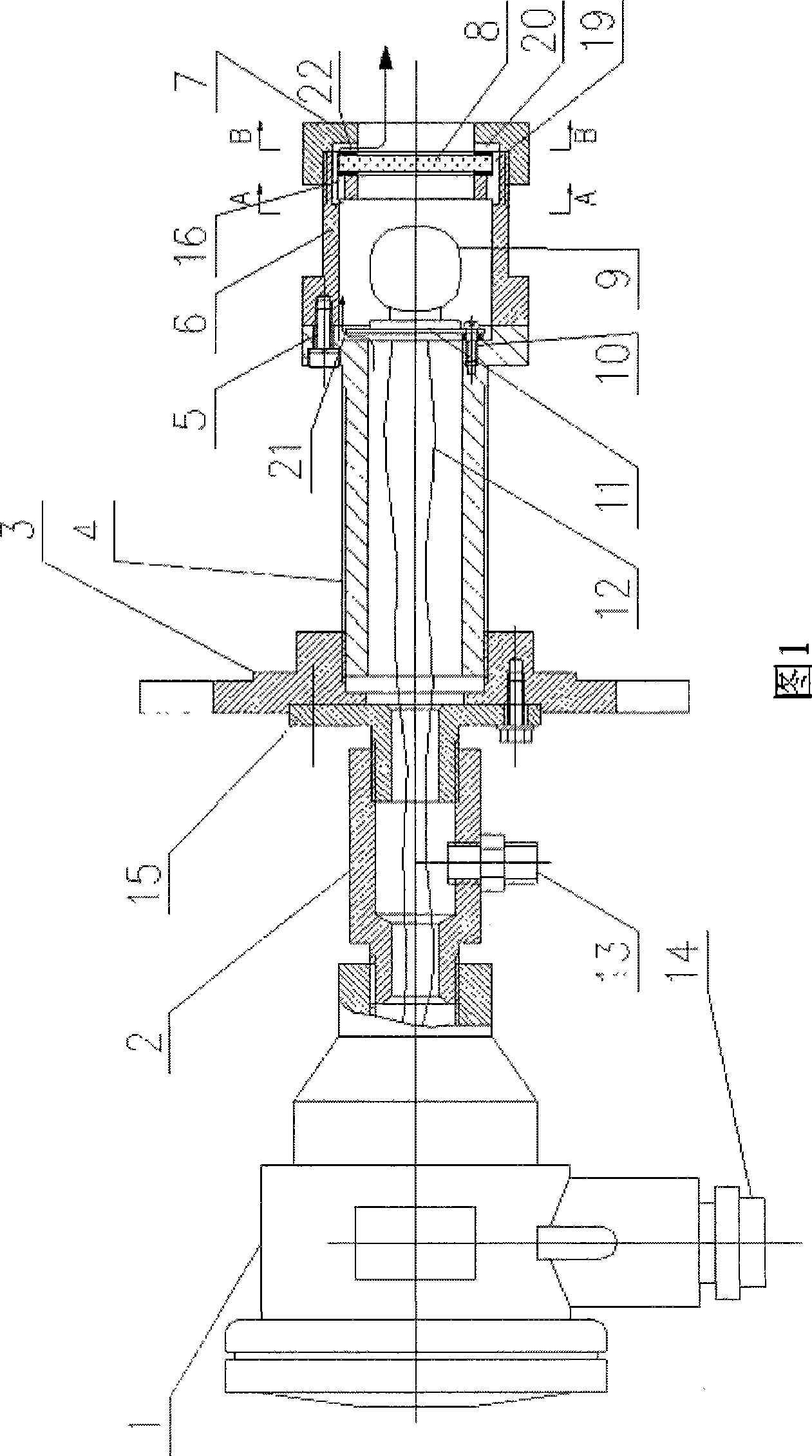

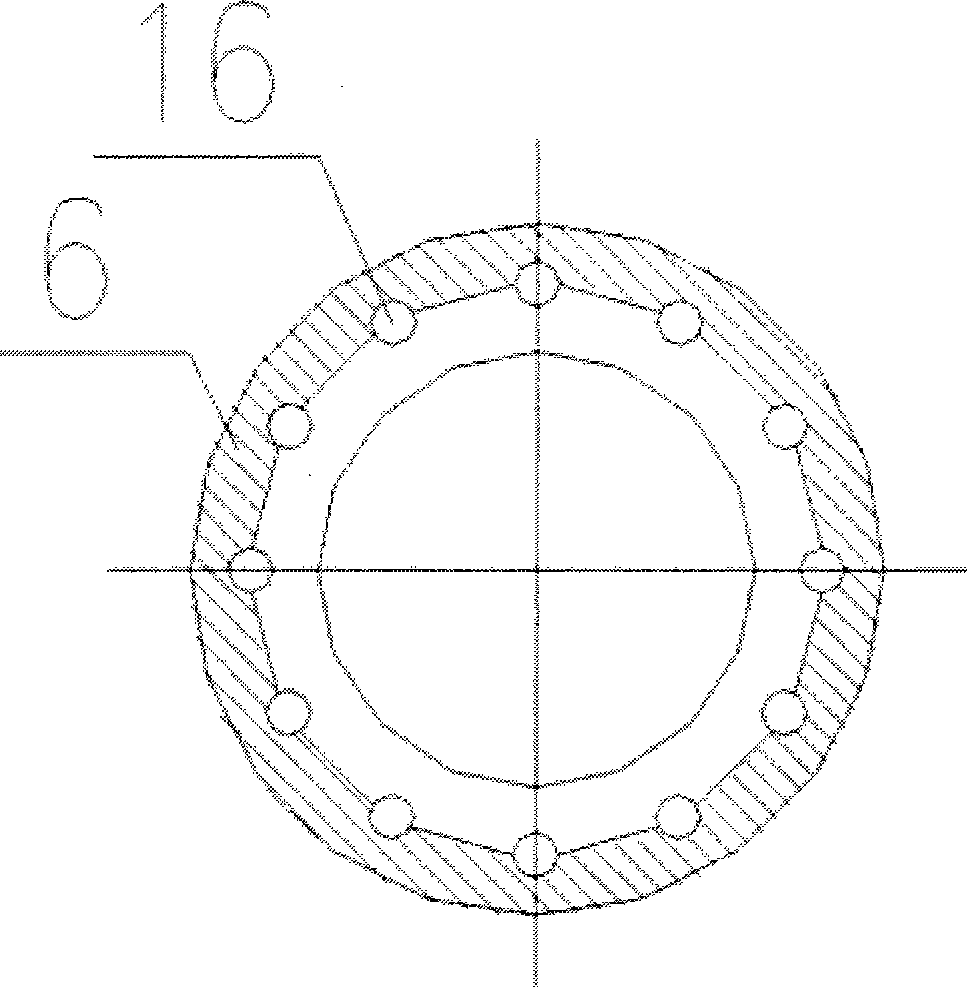

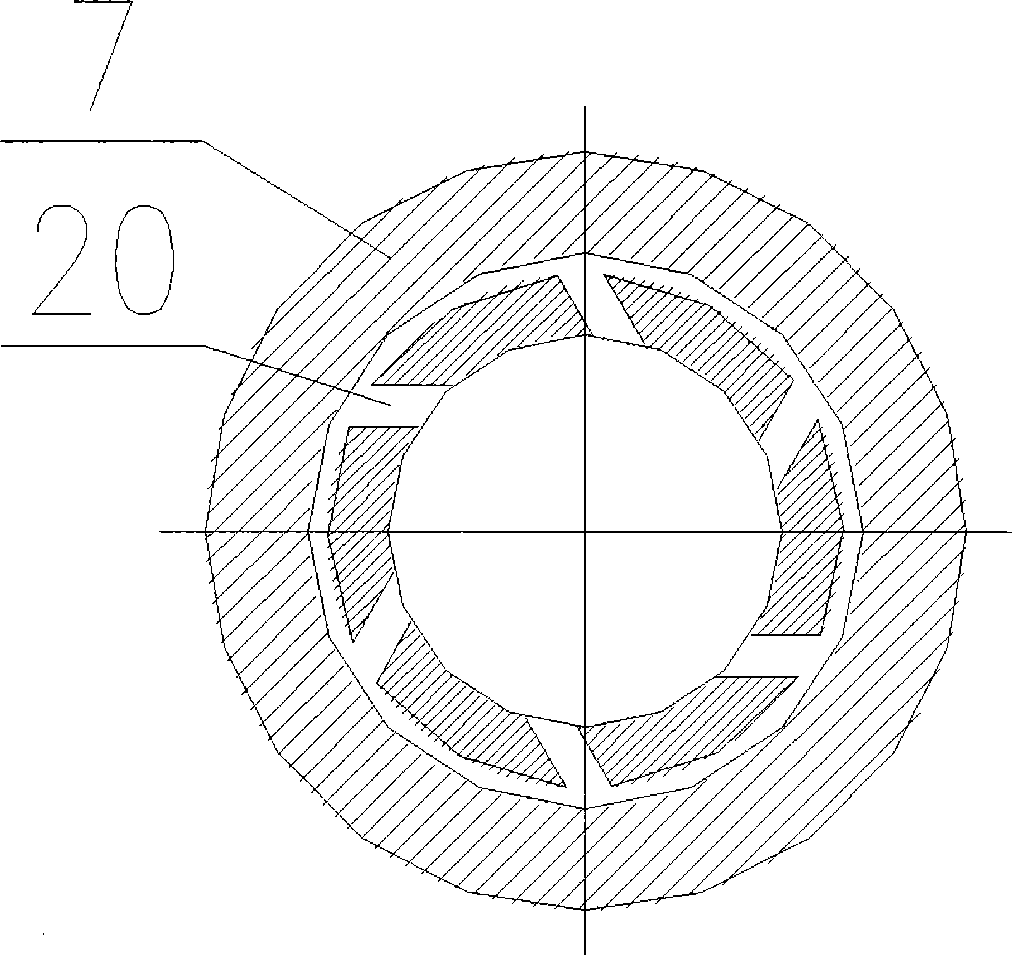

[0016] As shown in Figure 1, a kind of flame detector probe, it comprises explosion-proof junction box 1, is provided with cable connection port 14 on the explosion-proof junction box 1, and one end of explosion-proof junction box 1 and cooling air inlet pipe 2 is connected by thread, and cooling air The inner side of the other end of the inlet pipe 2 is provided with threads, through which the connection sleeve 15 is connected, the connection sleeve 15 is connected with one side of the double ear flange 3 by screws, and the double ear flange 3 and the flame detection cylinder 4 are threaded Connected, the flame detection cylinder 4 is connected with one end of the photocell protective cover 6 through the protective cover fixing screw 5 . The outside of the photocell protective cover 6 is threadedly connected to the photoelectric tube protective cover 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com