Forced centering plate and embedding method

A technology of centering plate and centering plate, which is applied in the field of measurement to achieve the effects of long service life, enhanced stability, and anti-tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

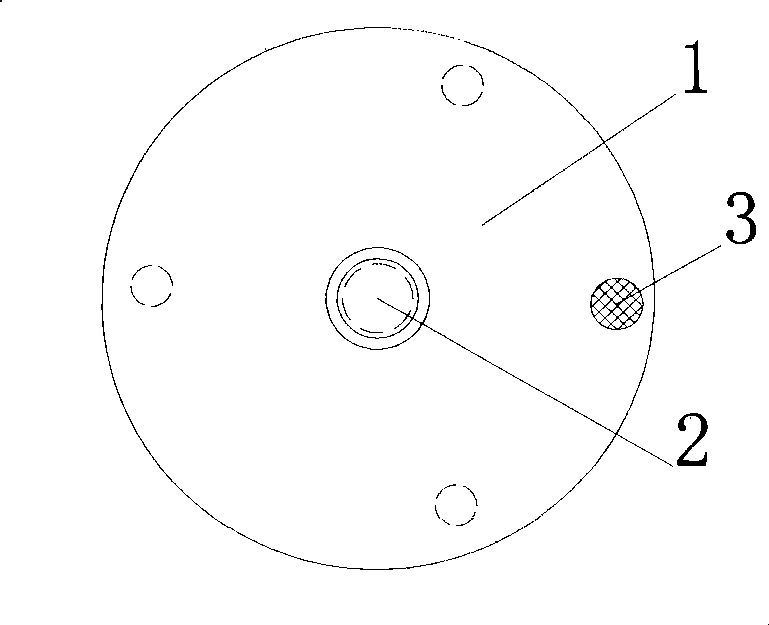

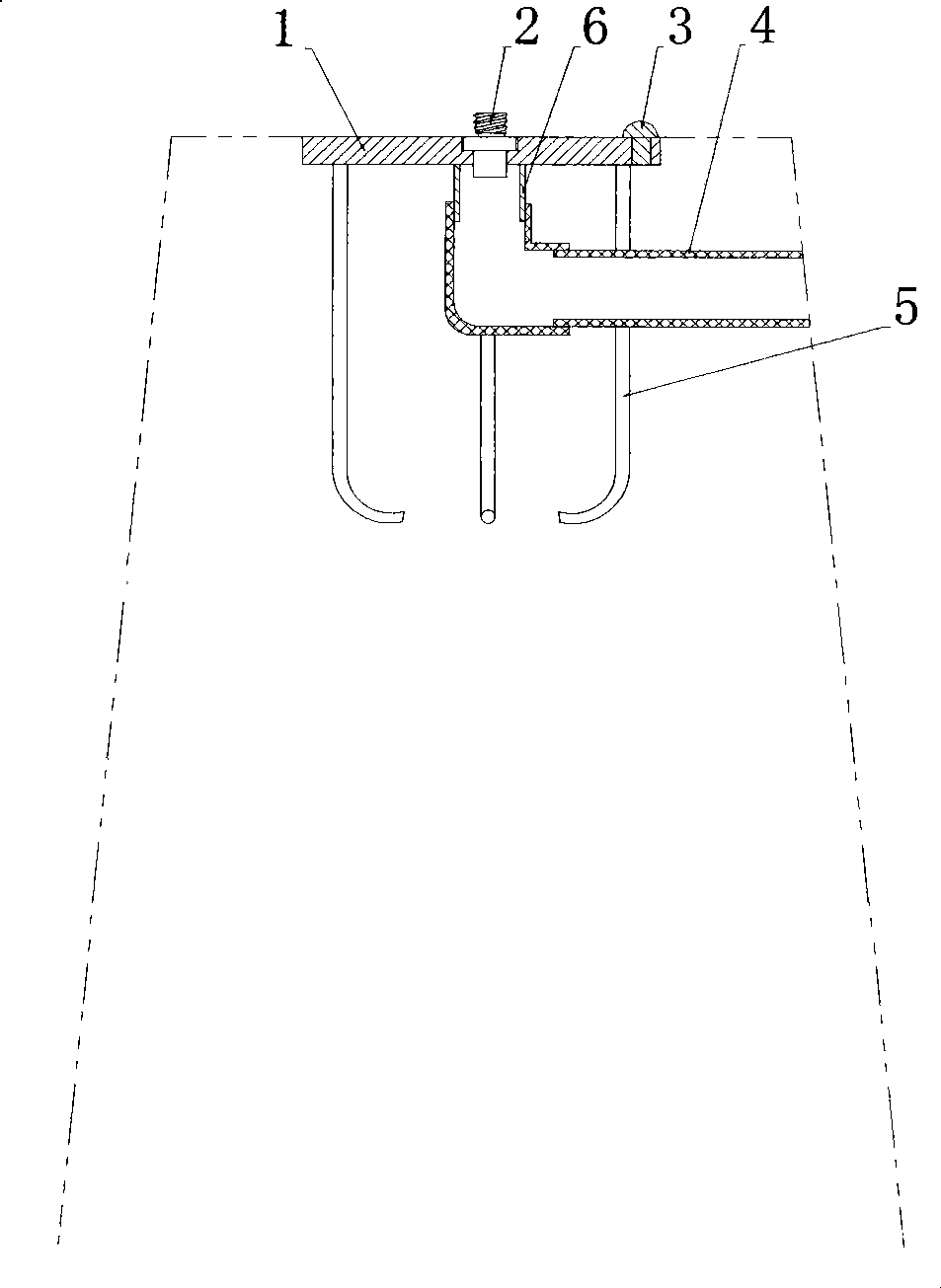

[0021] According to Figure 1, figure 2 As shown, a forced centering plate includes: a centering plate 1, a connecting bolt 2 is installed in the center hole of the centering plate 1, a leveling point 3 is also installed on the centering plate 1, and a connecting pipe is installed at the bottom of the centering hole of the centering plate 1 6. The PVC pipe 4 (rainwater diversion hole) connected to the connecting pipe 6, and at least two fixed steel bars 5 are also arranged on the bottom surface of the centering plate 1 .

[0022] The machining error of the center hole diameter of the centering plate 1 should not be greater than +0.1mm, and the diameter machining error of the connecting bolt 2 and the center hole should not be greater than -0.1mm.

[0023] Centering plate 1, connecting bolt 2 and leveling point 3 should be made of stainless steel.

Embodiment 2

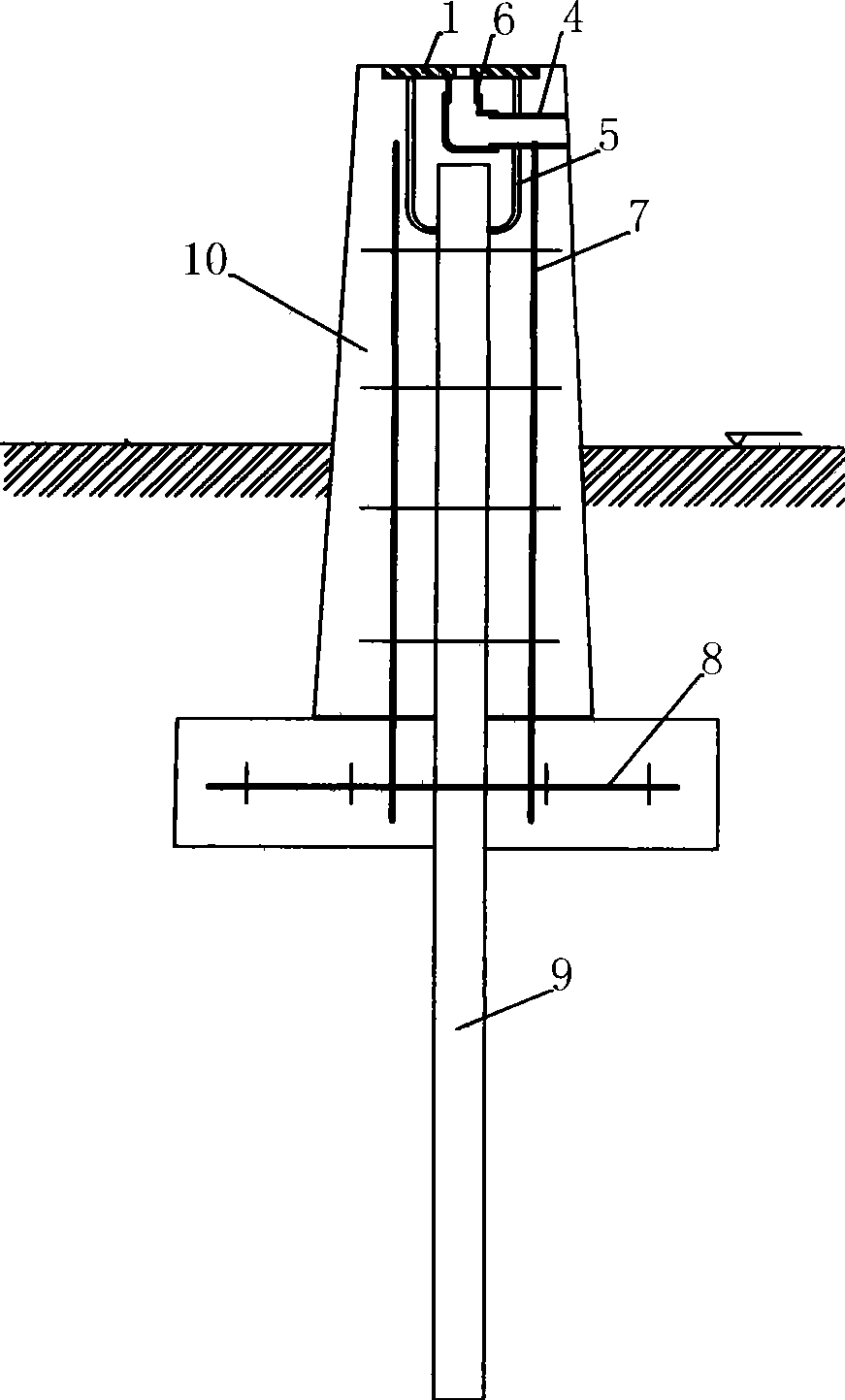

[0025] according to image 3 As shown, a method of embedding forced centering panels, the steps are as follows:

[0026] ① Excavate a square pit with a side length of 1-1.5m and a depth of 1.3-1.5m;

[0027] ②Drill a steel pipe 9 with a diameter of 400-600mm into the center of the pit, and its depth is 3-5m above the ground;

[0028] ③ Placing a 1-1.2m square reinforced chassis circle 8 under the horizontal plane 1-1.2m;

[0029] ④ Tie a square cylindrical reinforcement ring 7 with a height of 1.8-2.2m on the chassis reinforcement ring 8, and its side length is 250mm;

[0030] 5. Weld the fixed steel bar 5 of the forced centering plate on the steel pipe 9 top, the upper surface of the centering plate 1 of the forced centering plate must be kept in a horizontal state, and formwork is installed outside the reinforcement circle 7, 8;

[0031] ⑥Pour concrete so that the surface of the forced centering plate is flush with the horizontal plane of the centering observation pier 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com