Modified capacitor and method for manufacturing same

A manufacturing method and improved technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as increasing the difficulty of device manufacturing, increasing the size of semiconductor devices, and affecting the area of pixel arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The improved capacitor of the present invention and its manufacturing method will be further described in detail below.

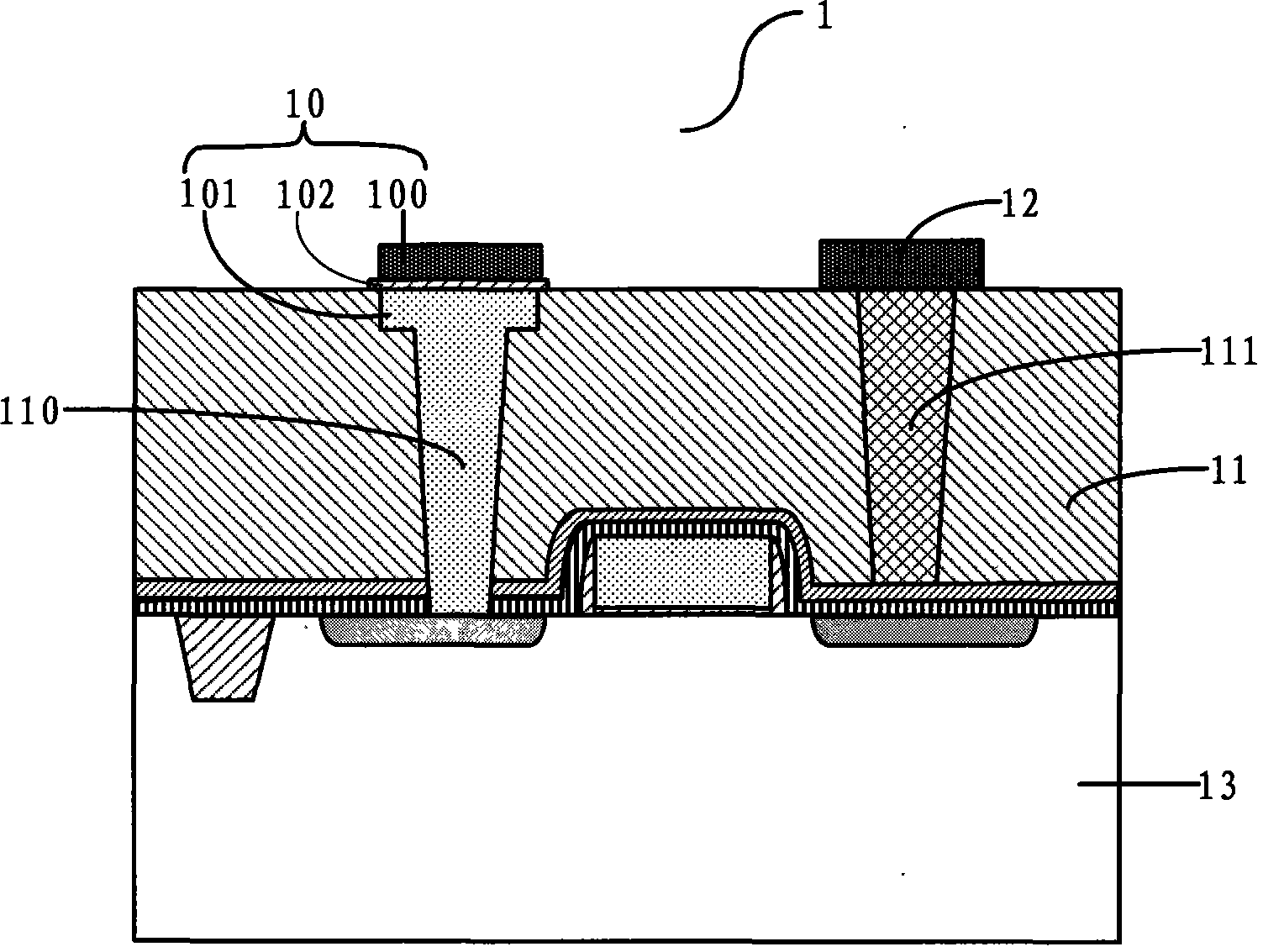

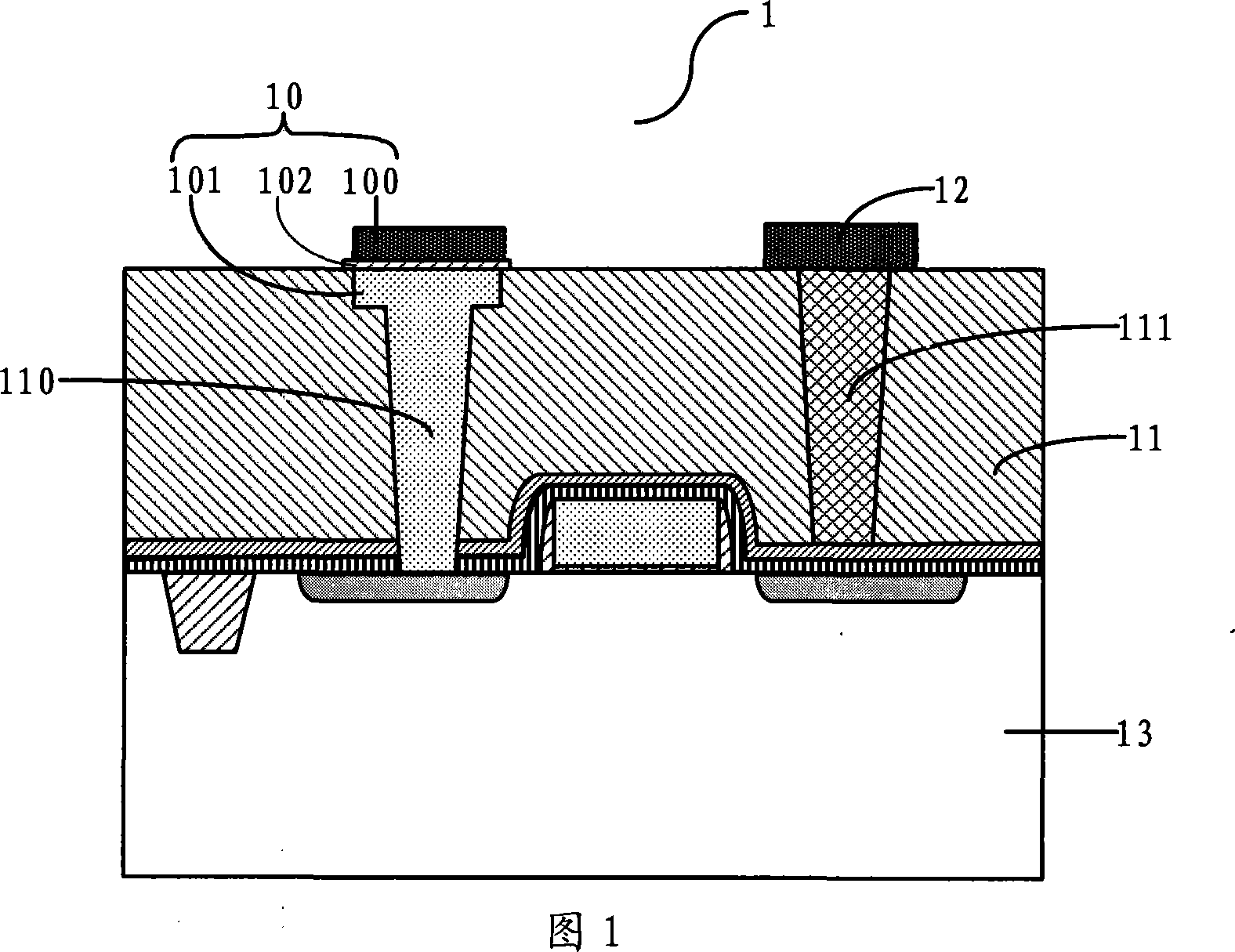

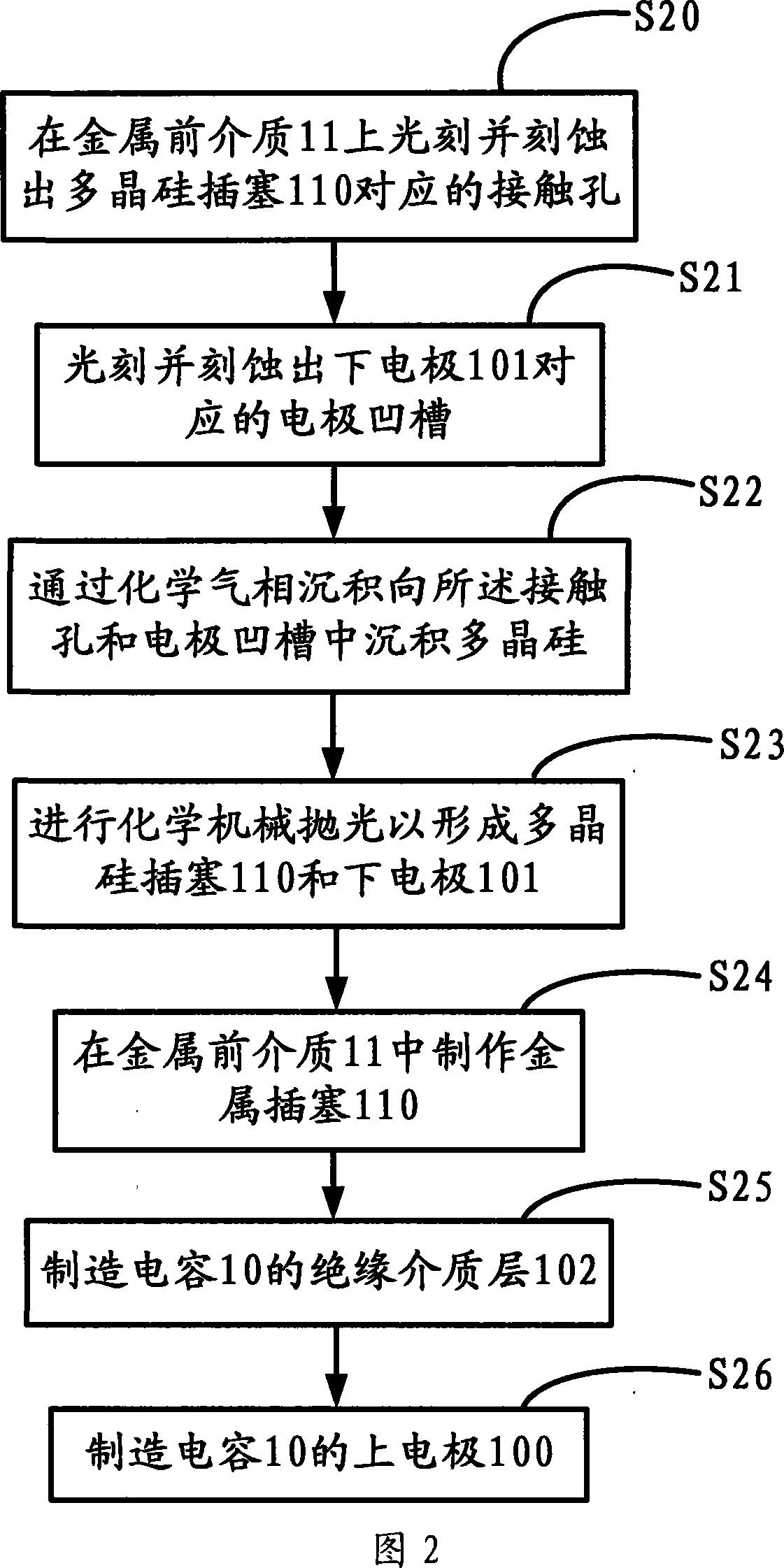

[0021] Referring to FIG. 1, the improved capacitor 10 of the present invention is arranged in a semiconductor device 1 that has fabricated a pre-metal dielectric 11 and a first metal layer 12, and the pre-metal dielectric 11 is provided with connected electrode grooves and contacts holes (not shown), and the cross-sectional area of the electrode groove is larger than the maximum cross-sectional area of the contact hole. The capacitor 10 includes upper and lower electrodes 100, 101 and an insulating medium layer 102 sandwiched between the upper and lower electrodes 100, 101, the upper electrode 100 is arranged in the first metal layer 12, and the lower electrode 101 is arranged in the first metal layer 12. The bottom electrode 101 is also connected to the silicon substrate 13 of the semiconductor device 1 through the polysilicon plug 110 disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com