A Single Magnetic Core Complicated Waveform Current Sensor

A technology of current sensor and single magnetic core, which is applied in the direction of only measuring current, measuring current/voltage, instruments, etc. It can solve the problems of increasing the volume of the current sensor, complicating the structure, and increasing the cost, so as to expand the measurement range and frequency and reduce the volume , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

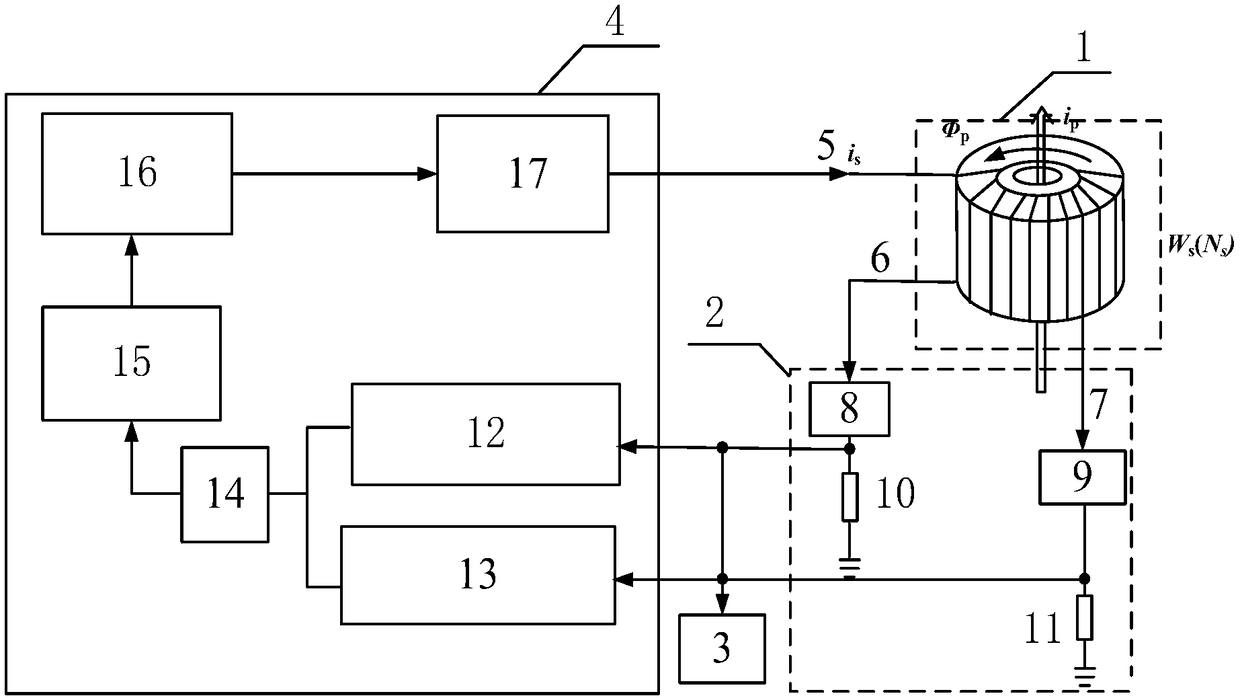

[0057] The composition of a single magnetic core complex waveform current sensor in this embodiment is as follows: figure 1 As shown, the number of turns of the primary coil of the current probe 1 is 1 turn, and the number of turns of the secondary coil is 50 turns. The material used for the magnetic core of the current probe 1 is an ultrafine crystal soft magnetic material, and its saturation magnetic flux density is B s =1.2T, coercive force H c -8 ~10 -6 , the magnetic permeability is 30000-80000H / m, the inner diameter of the ring magnetic core is 5.1mm, the outer diameter is 11.2mm and the height is 5.8mm. The material used for the winding is enameled wire with a diameter of 0.38mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com