Static coil type micromechanical electromagnetic vibration energy collector based on frequency boost conversion

A technology of energy harvester and fixed circle miniaturization, which is applied in the direction of electromechanical devices and electrical components, can solve problems such as the limitation of induced electromotive force, the complexity of device manufacturing process, and the change of cantilever beam stiffness, so as to achieve high output voltage and output power, and realize batch production The effects of modernized production and high frequency adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

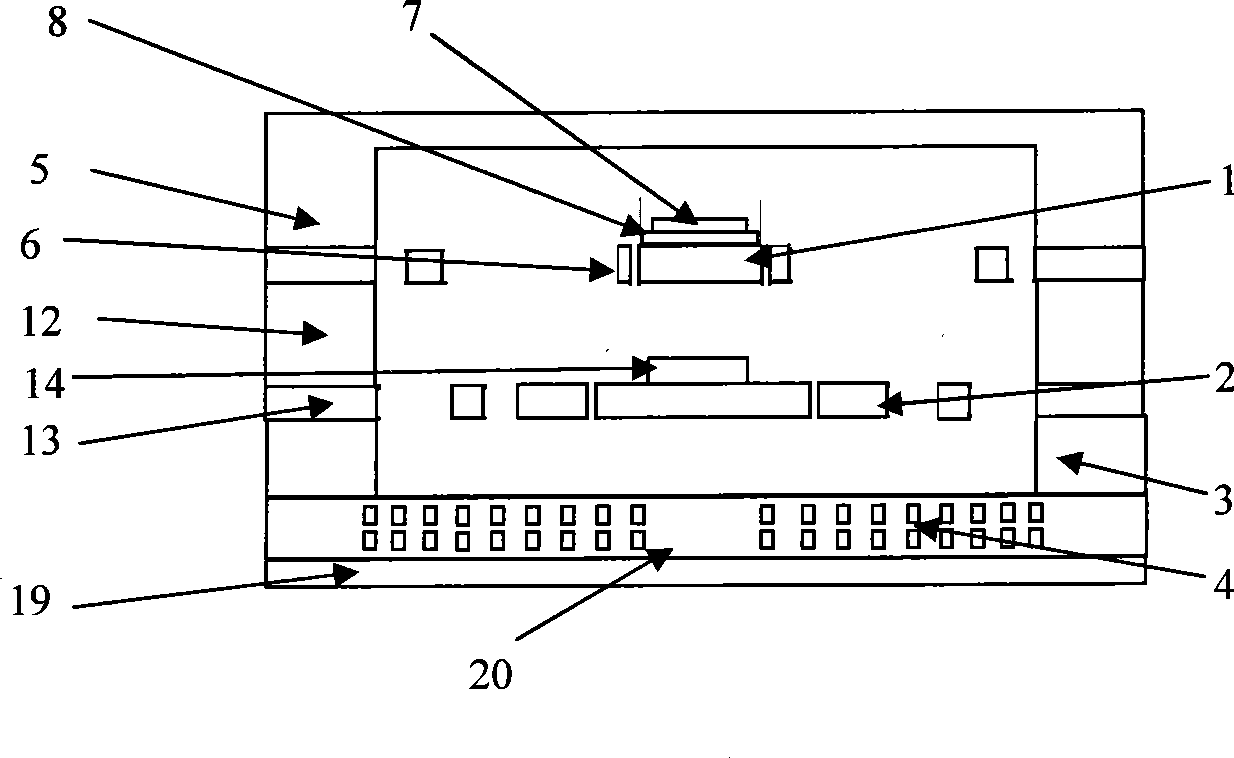

[0034] Such as figure 1 As shown, this embodiment includes: a low-frequency vibration pickup table 1 , a high-frequency resonance table 2 , a spacer 3 and an induction coil 4 . The high-frequency resonance table 2 is located above the induction coil 4 , the high-frequency resonance table 2 is located below the low-frequency vibration pickup table 1 , and the gasket 3 is located between the high-frequency resonance table 2 and the induction coil 4 .

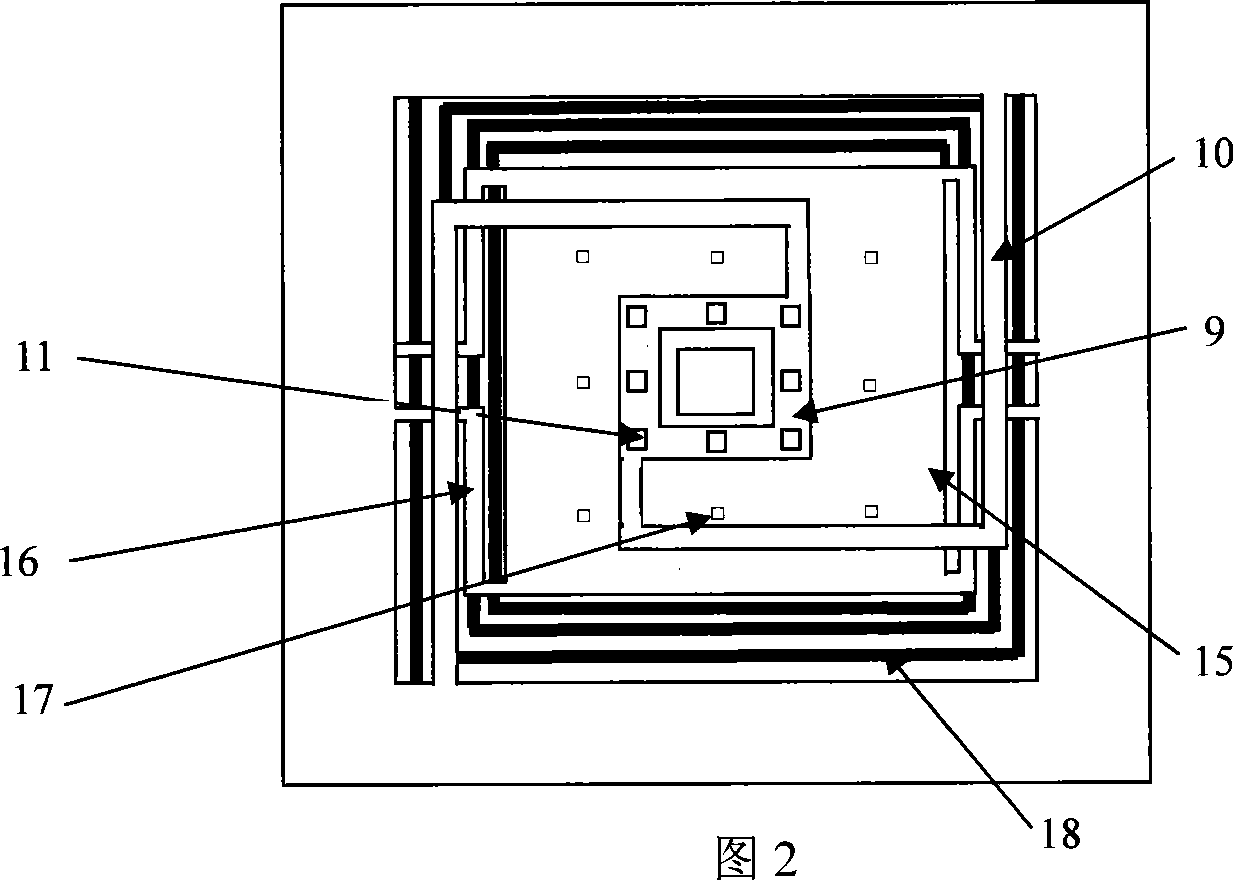

[0035] Such as figure 1 , 2, the low frequency pickup table 1 includes: a top cover 5, a metal plane spring 6, a vibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com