Thermoplastic belt connector with fingers

A technology of connectors and fingers, applied in the field of connectors of thermoplastic endless belts, can solve the problems of inconvenient, broken belts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

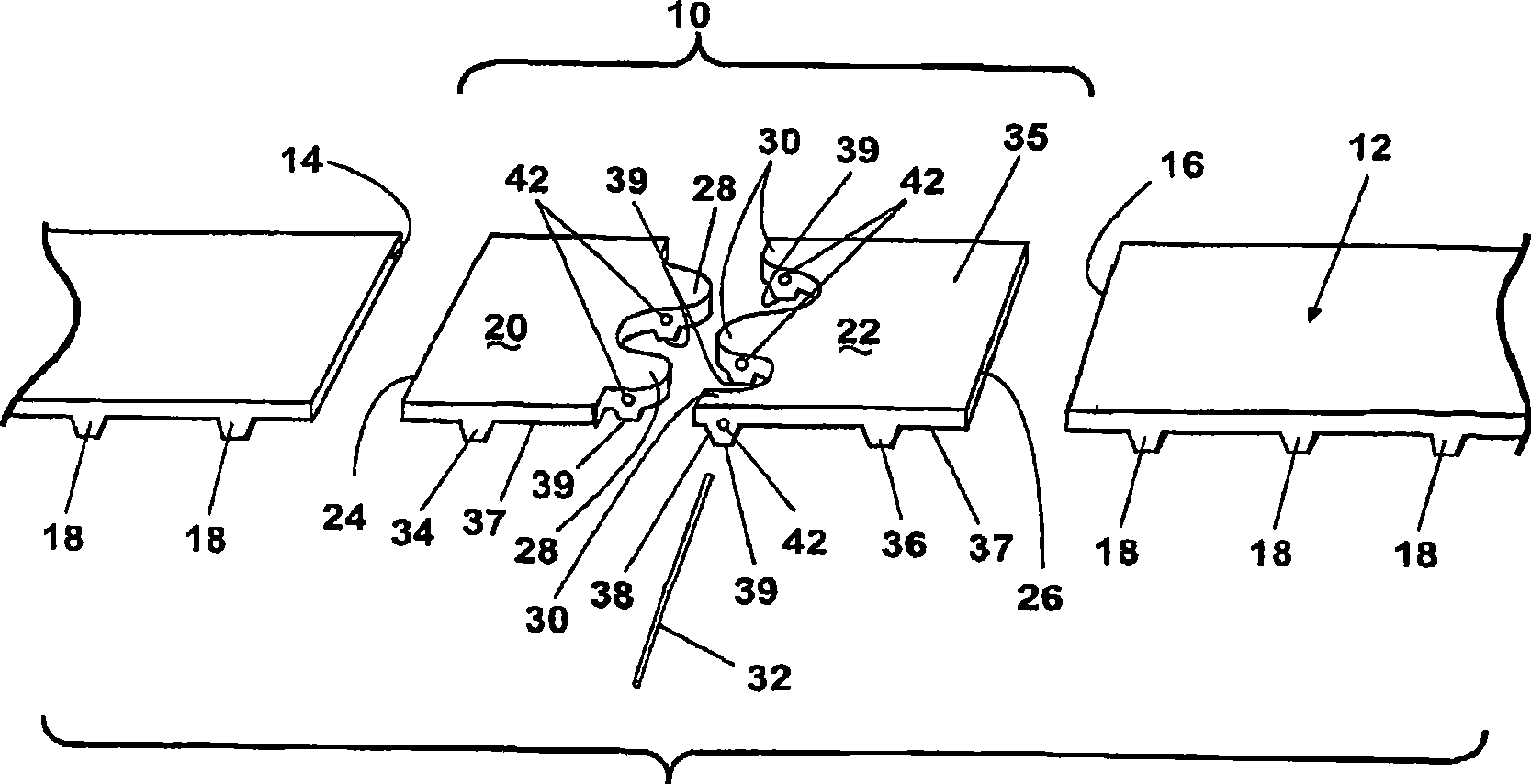

[0032] now refer to figure 2 , the strap connector 10 is shown in conjunction with the strap 12 with which it will be used. The belt 12 is the same as that described above with reference to the prior art, except that it is not endless. Strap 12 is a strap segment having a first end 14 and a second end 16 . Each end preferably forms the middle two teeth 18 . The strip 12 may be made by any method such as rolling, extrusion and / or injection molding.

[0033] The ribbon connector 10 includes two leaves 20,22. Each leaf has butt ends 24, 26 sized for butt welding to respective first and second end portions 14, 16 in conventional manner. Each leaf also has a plurality of knuckles 28 , 30 opposite butt ends 24 , 26 , which when connected by pins 32 will form a connection. Preferably, each leaf has teeth 34, 36 positioned such that when the butt ends 24, 26 are welded to the first and second ends 14, 16 on the belt, the pitch of the teeth will maintain constant.

[0034] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com