Probing robot

A robot and chassis technology, applied in the field of detection robots, can solve the problems that the robot is prone to rollover and unable to complete the exploration task

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

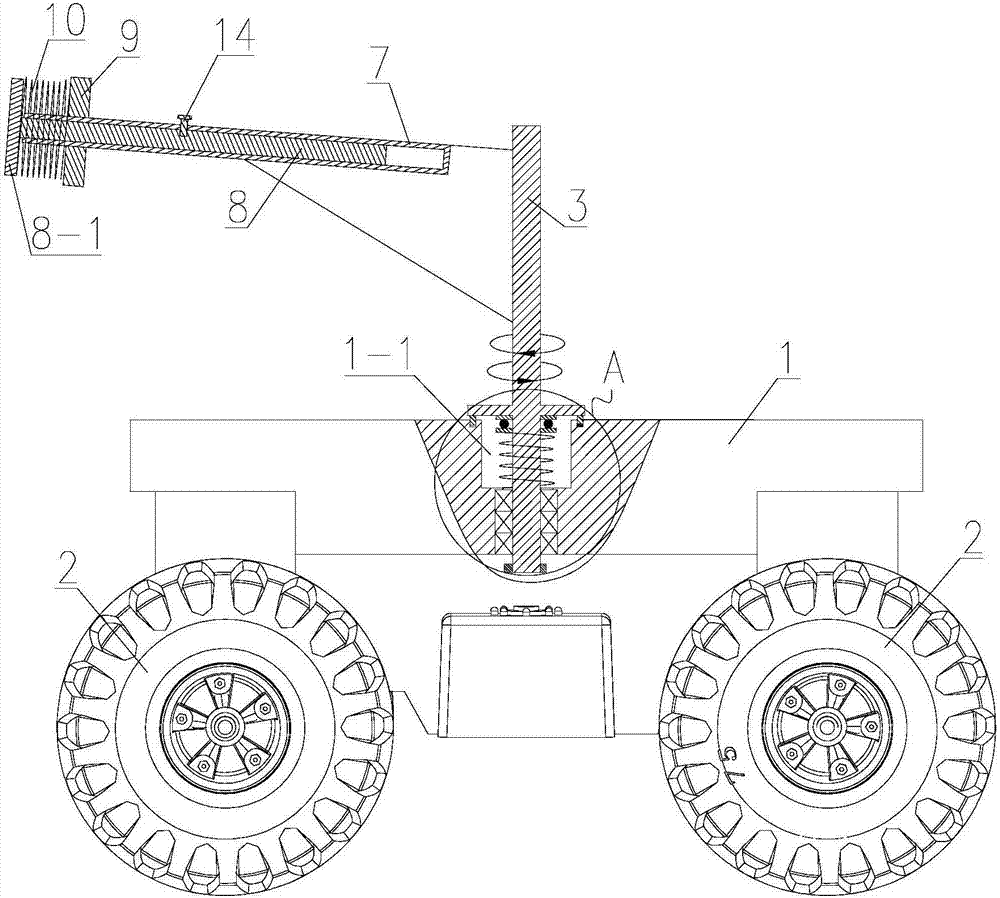

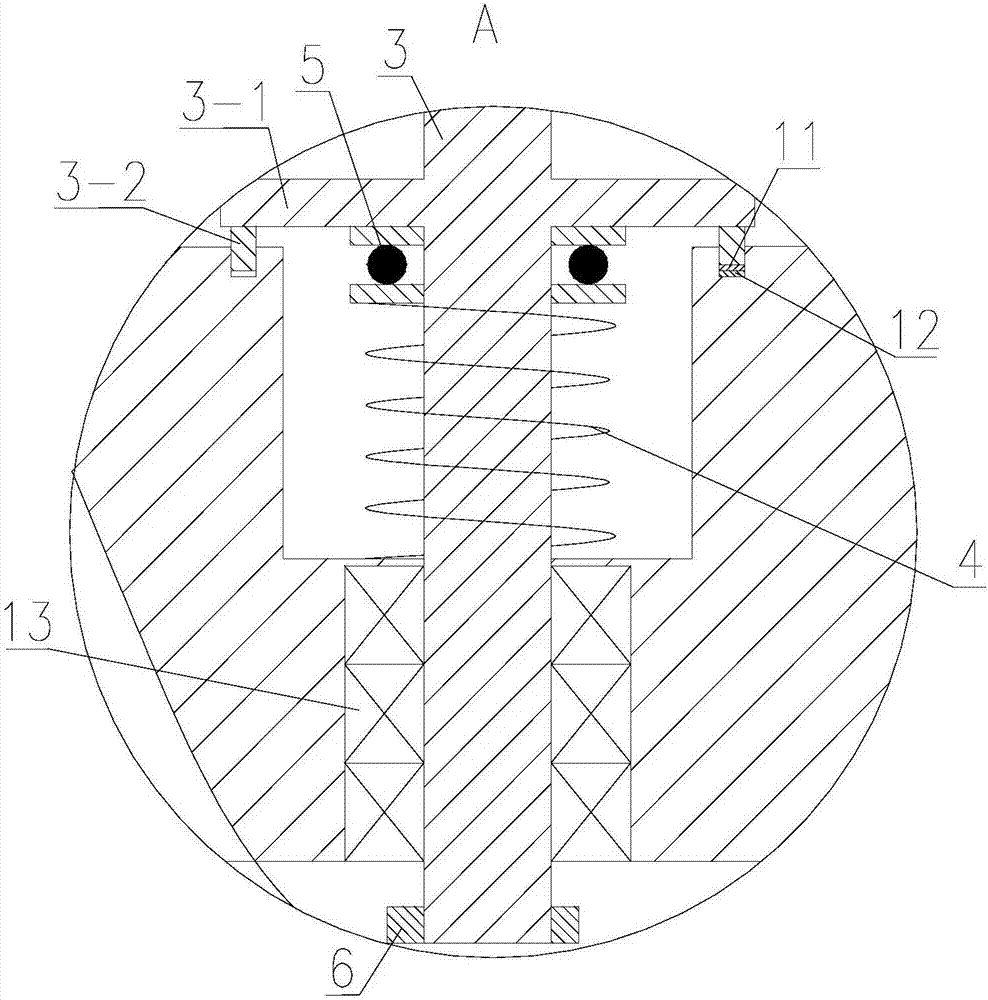

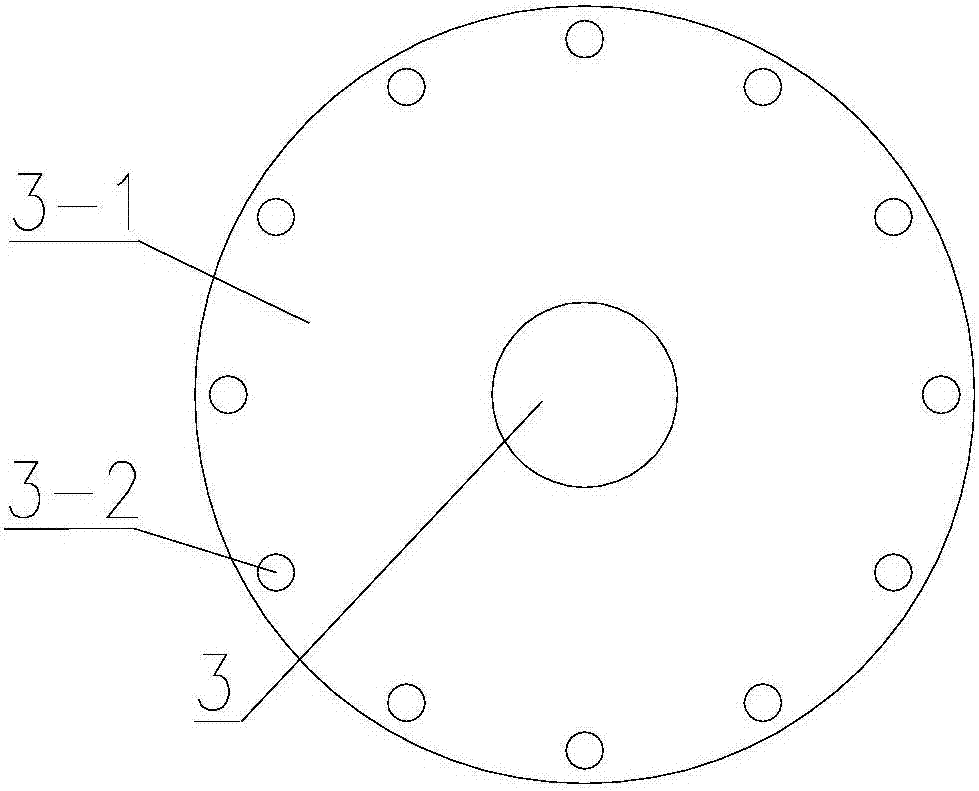

[0019] Such as Figure 1-5 As shown, a detection robot includes a chassis 1 and a roller 2 arranged below the chassis 1. The four sides of the chassis 1 are provided with cameras and sensors for detection, and the upper surface of the chassis 1 is provided with a spring cavity 1-1 downward. , the bottom surface of the spring chamber 1-1 is provided with a shaft hole, a shaft 3 is inserted in the shaft hole, a flange 3-1 is fixed on the shaft 3, a first spring 4 is set on the shaft 3, and the elastic force of the first spring 4 The direction is consistent with the axial direction of the rotating shaft 3. The first spring 4 is located between the flange 3-1 and the bottom surface of the spring chamber 1-1. An end bearing 5 is arranged between the first spring 4 and the flange 3-1. The flange The lower surface of the 3-1 is provided with a number of post 3-2, and the upper surface of the chassis 1 is provided with a number of sockets 1-2 corresponding to the post 3-2, and the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com