High-gradient magnetic separation machine

A high-gradient magnetic separator and sorting technology, applied in the direction of high-gradient magnetic separator, etc., to achieve the effect of reducing maintenance cost, improving service life and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

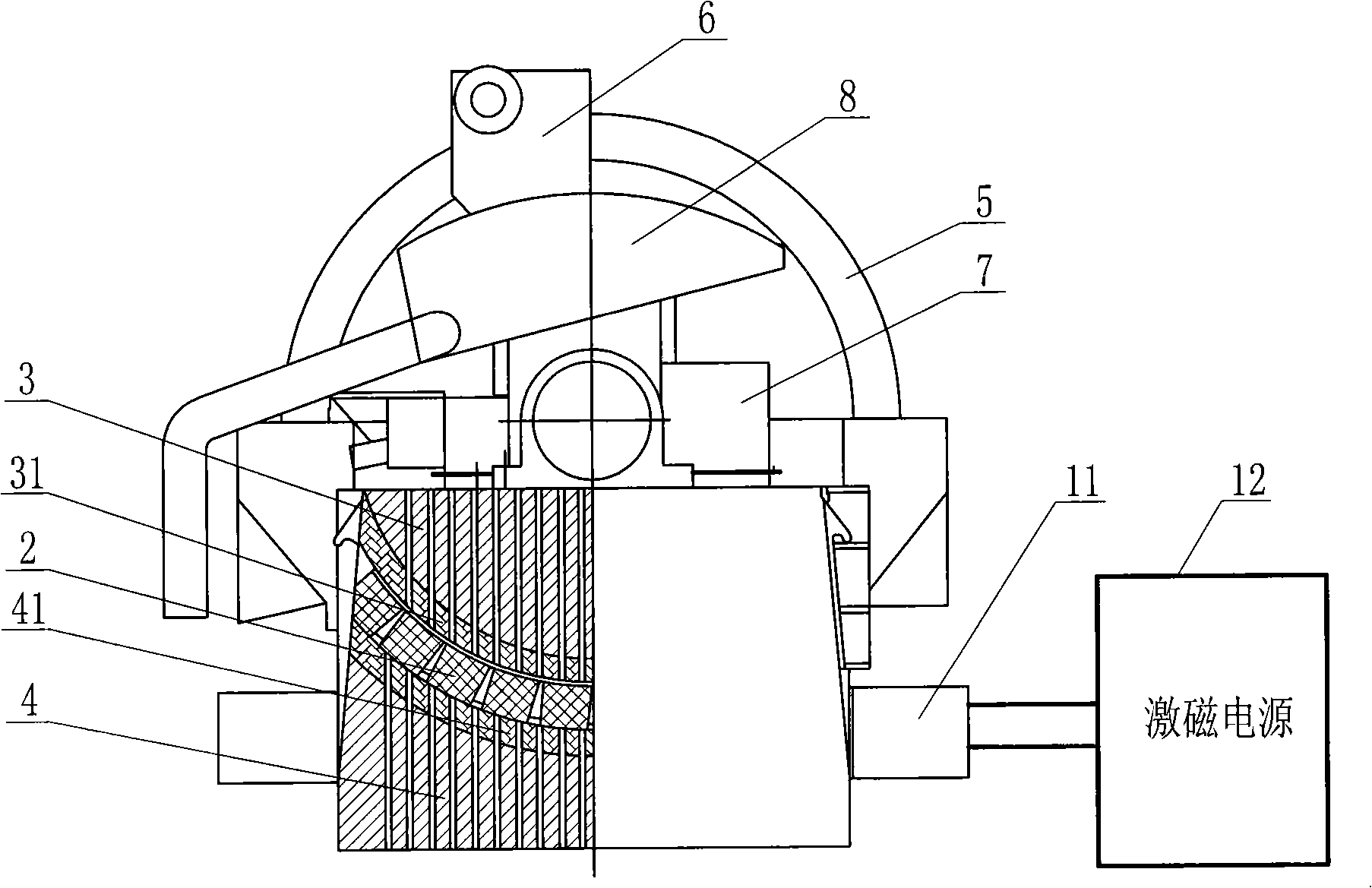

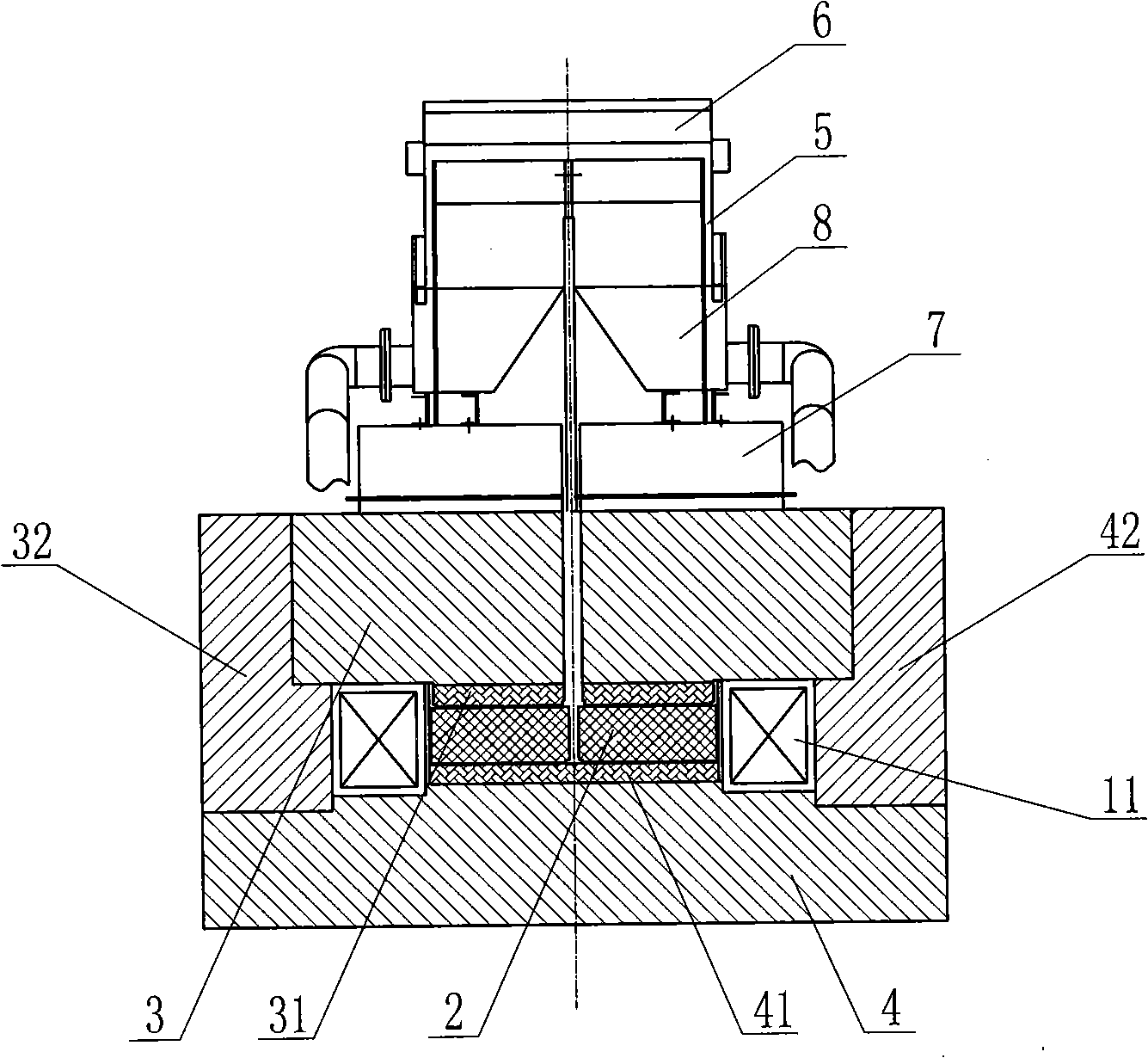

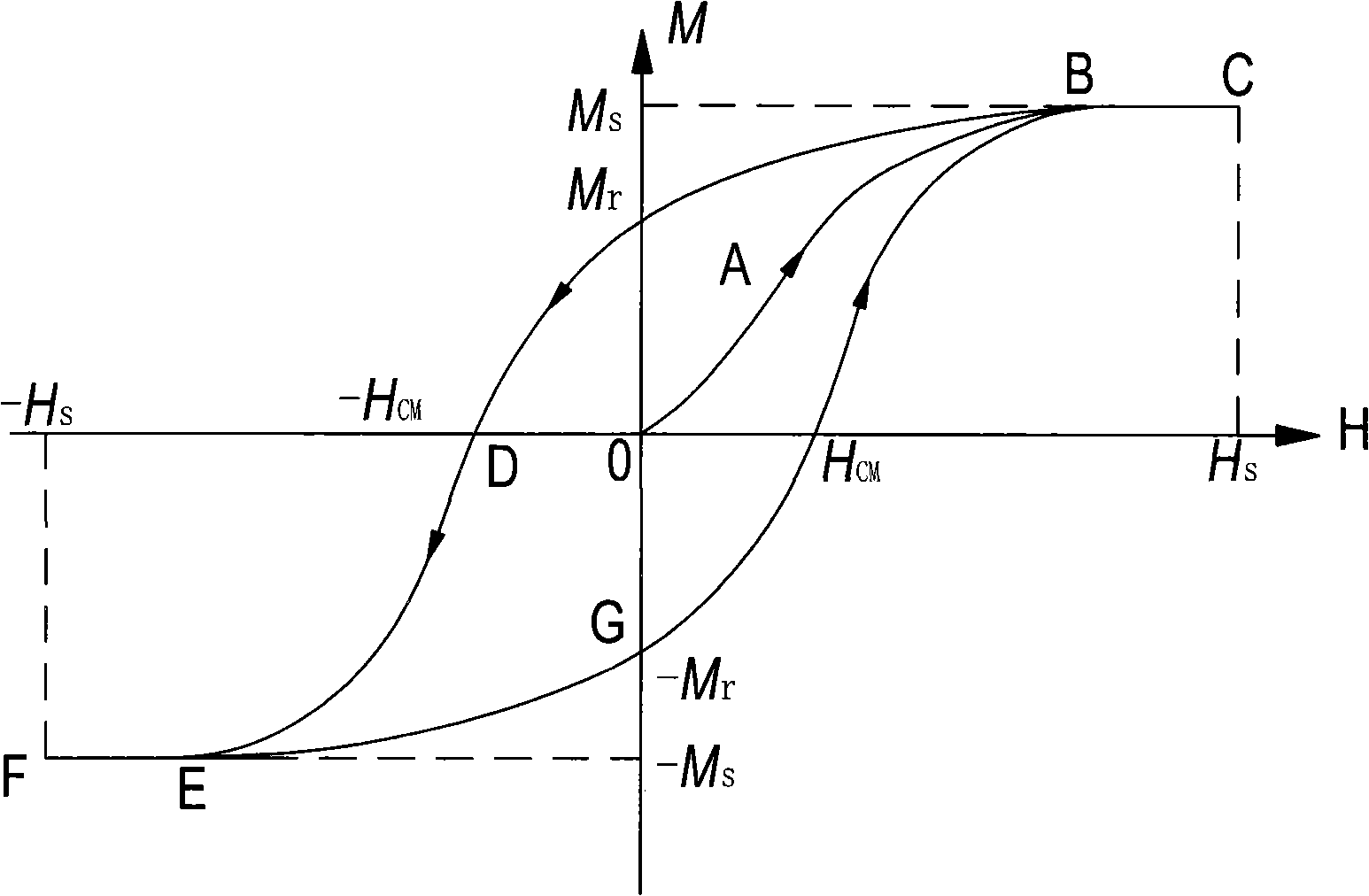

[0014] Such as Figure 1 ~ Figure 2 As shown, a kind of high gradient magnetic separator described in the present invention comprises sorting ring and its driving device, ore feeding device 7, concentrate gas-water unloading device and concentrate collecting device 8, wherein the sorting ring includes a swivel 5 and the magnetic gathering medium stack 2 installed on the swivel 5, the upper yoke 3 located inside and outside the swivel 5, the upper magnet 31, the lower yoke 4, and the lower magnet 41, and the upper magnet 31 corresponds to the lower magnet 41 It is characterized in that it also includes a charging and demagnetizing device installed under the swivel ring, which can charge and demagnetize the upper magnet 31 and the lower magnet 41 respectively. Electromagnetic coil 11 and excitation power supply 12 connected to electromagnetic coil 11 . Among them, the swivel ring 5 is a vertical double-ring structure, and a turntable connecting the double rings as a whole is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com